Rotation axis spatial state calibrating method for swinging arm-type contourgraph

A technology of space state and calibration method, which is applied to instruments, measuring devices, optical devices, etc., can solve the problem that the calibration of the rotation axis of the swing arm profiler cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and features of the present invention clearer, the present invention will be further described in detail below in combination with specific implementation cases and with reference to the accompanying drawings.

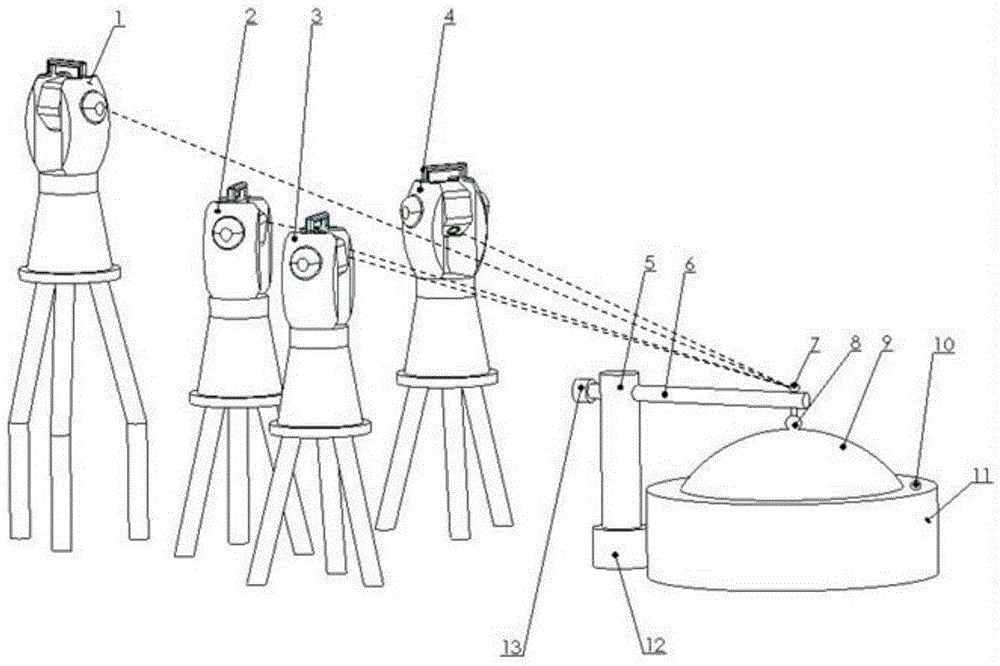

[0017] Such as figure 1 As shown, the equipment for the calibration method of the spatial state of the rotating axis of the swing arm profiler includes: 4 laser trackers 1, 2, 3, 4; cross arm shaft 5; cross arm 6; laser tracker target ball 7; Profilometer measuring head 8; workpiece to be measured 9; peephole 10; workpiece turntable 11; swing arm turntable 12; counterweight 13. in:

[0018] 4 laser trackers 1, 2, 3, 4 respectively track the target ball 7 and the cat's eye 10 of the laser tracker when calibrating the axis of the cross arm and the axis of the workpiece turntable;

[0019] The laser tracker target ball 7 and cat's eye 10 are installed on the cross arm 6 and the workpiece turntable 11 through a spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com