Nozzle-adjustable steam ejector

An injector and adjustable technology, which is applied in jet pumps, non-displacement pumps, machines/engines, etc., can solve problems such as poor sealing effect, achieve low processing and manufacturing costs, save power steam, and be easy to disassemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

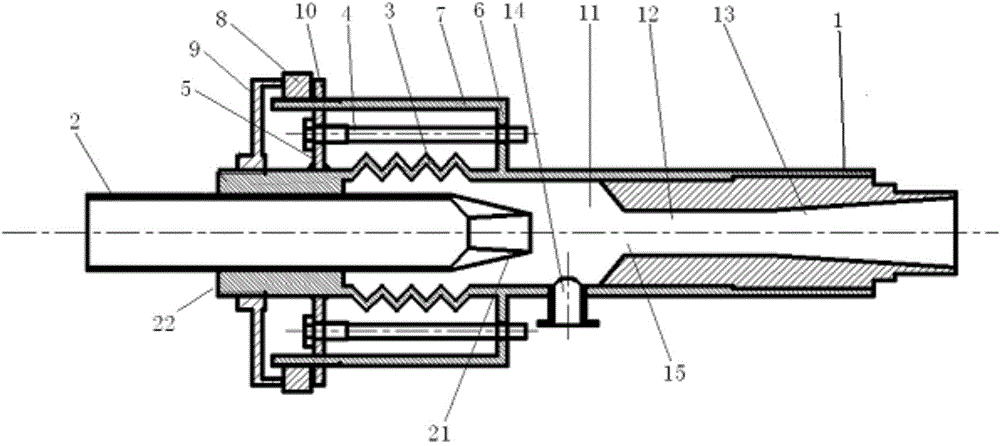

[0029] Such as figure 1 As shown, a steam injector with an adjustable nozzle includes an injector housing 1 , a spray pipe 2 and a bellows 3 . The injector housing 1 has a suction chamber 11, a mixing chamber 12 and a diffuser chamber 13 inside. The connection between the suction chamber 11 and the mixing chamber 12 is a throat 14. The injector housing 1 is also provided with a valve communicating with the suction chamber 11. Introduce steam inlet 15. The nozzle 2 has a nozzle 21 extending into the suction chamber 11, the nozzle 21 is facing the throat 14, and the axis of the nozzle 2 is at the center of the throat 14.

[0030] The periphery of the nozzle pipe 2 is sealed with a fixed ring 22, and the fixed ring 22 and the nozzle pipe 2 are welded into an integral structure. One end of the bellows 3 is fixedly connected to the fixed ring 22, and the other end is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com