Automatic and fast spiral tooth-shaped butt joint structure of foundation piles

A foundation pile and tooth shape technology, which is applied in the field of automatic fast spiral tooth shape butt joint structure of foundation piles, can solve the problems of cumbersome operation, time-consuming and costly, etc., and achieve the effect of simple structure, low cost, automatic fast spiral tooth shape butt joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

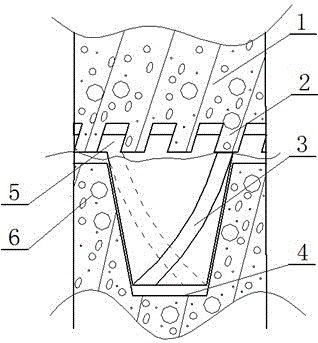

[0012] In the figure, the foundation pile automatic fast spiral tooth-shaped docking structure includes the upper foundation pile 1 to be connected, the frustum teeth 2, the external thread frustum 3, the internal thread frustum groove 4, the cone wall teeth 5 and the lower foundation pile to be connected. Pile 6; at the end of the lower end of the foundation pile 1 to be connected on the upper part, an externally threaded conical frustum 3 with raised threads is axially provided, and the outer threaded conical frustum 3 is evenly distributed around the upper end of the externally threaded conical frustum 3. The frustum teeth 2 and the frustum alveolar grooves of the conical frustum 3 are spaced in the same helical direction as the threads on the threaded conical frustum 3. At the end of the lower end to be connected to the upper end of the foundation pile 6, an inner thread that matches the external threaded conical frustum 3 is axially provided. Threaded frustum of conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com