An automatic control device for mesh tension in a weaving machine

A technology of automatic control device and net weaving machine, which is applied in the directions of knotting netting, textile and papermaking, knotting, etc. , the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

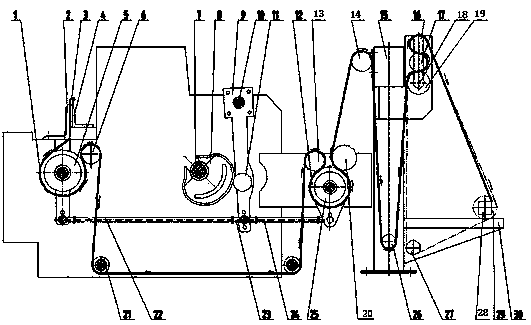

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] An automatic control device for mesh tension in a net weaving machine, which is provided with a swing arm 9, a group of active roll rolls, a set of passive roll rolls and a set of take-up rolls, the swing arm 9 is connected to the inner and outer wall panels through a short shaft 10, The bottom of the swing arm 9 is provided with a bearing assembly 11, the bottom of the bearing assembly 11 is fixed with a joint bearing 23, the side of the swing arm 9 is provided with a main shaft 7, the main shaft 7 is provided with a roll net cam seat, and the roll net cam seat is fixed with a roll net cam 8 , the active web roll group is provided with a main web roll 1 and a main web overrunning clutch 5, a shuttle hook 3 is provided on the main web roll 1, and a shuttle hook angle iron 2 and a net guide angle are respectively arranged on both sides of the hook 3. Iron 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com