Automatic conveyor for forklift differential assembly

A technology of automatic conveying device and forklift differential, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc. It can solve the problems of high labor intensity, easy falling off of workpieces, time-consuming and labor-intensive problems, so as to reduce labor intensity and transport The effect of complete process safety and reliable conveying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

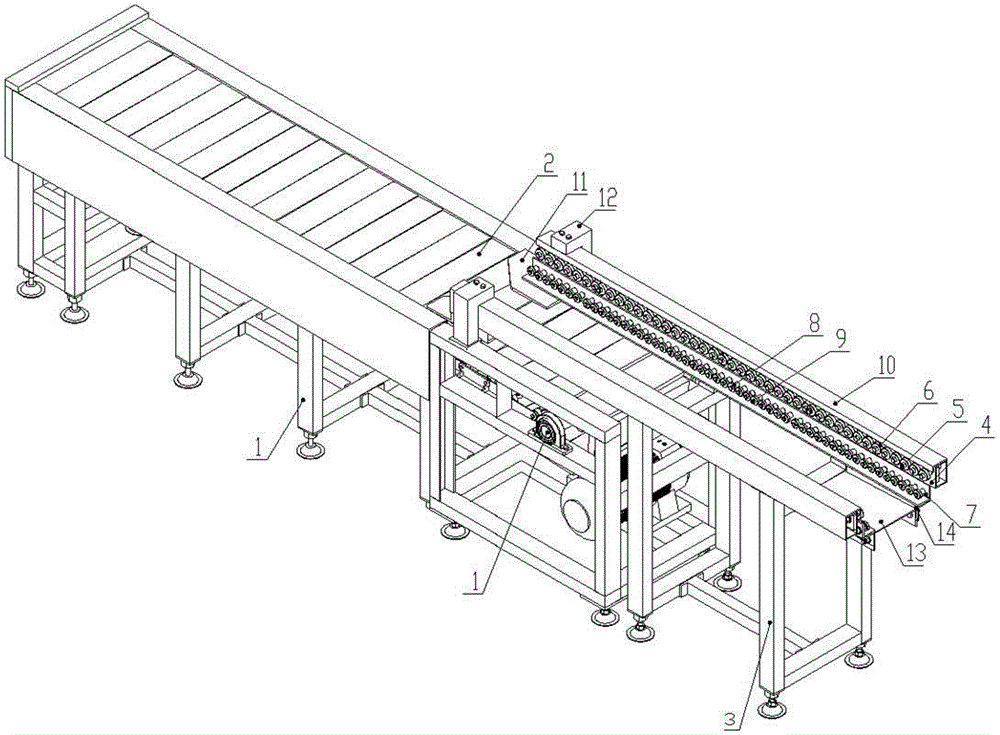

[0027] see figure 1 , the automatic conveying device for forklift differential assembly includes a plate chain conveying mechanism 1 and a roller conveying mechanism composed of a frame, a chain transmission mechanism and a motor. The chain transmission mechanism includes a transmission chain, which is straddled on two parallel chain shafts, and the transmission chain is equipped with a chain plate 2 to form a plate surface.

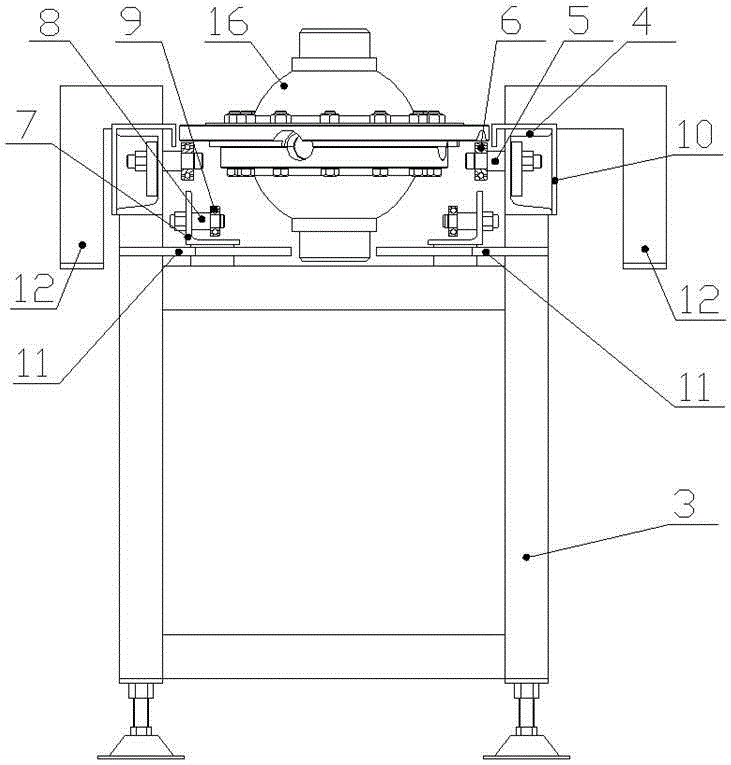

[0028] see image 3 , There is a height difference between the axis lines of two parallel chain shafts in the plate chain conveying mechanism 1, that is, the axis line of one chain shaft is higher than the axis line of the other chain shaft, and the height difference is 25 mm. A downward inclination angle α is formed between the plate surface formed by the chain plate 2 on the relatively low side chain shaft and the horizontal plane, and the inclination angle α is 2 degrees.

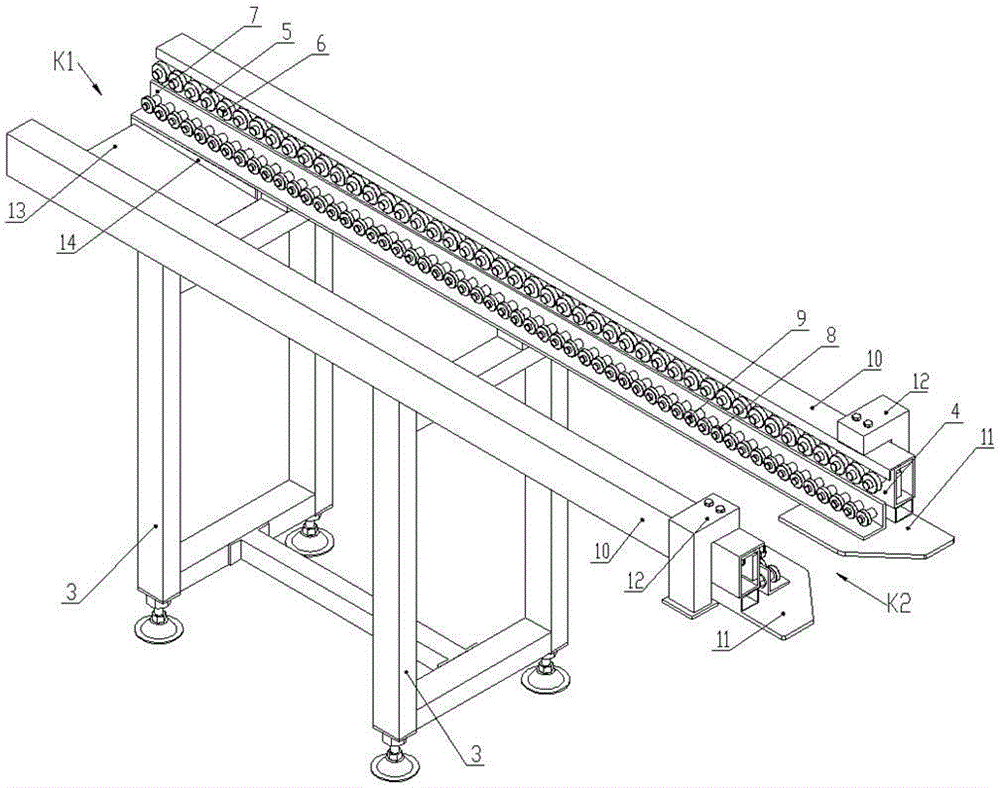

[0029] see figure 2 , the raceway conveying mechanism includes a frame-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com