Safety shaking frame for constructional engineering

A construction engineering and safety technology, applied in portable hoisting devices, hoisting devices, clockwork mechanisms, etc., can solve problems such as mud shaking, limited arm extension length, awkward posture of construction workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objects and advantages of the present invention more clear, the present invention will be specifically described below with reference to the embodiments. It should be understood that the following text is only used to describe one or more specific embodiments of the present invention, and does not strictly limit the protection scope of the specific claims of the present invention.

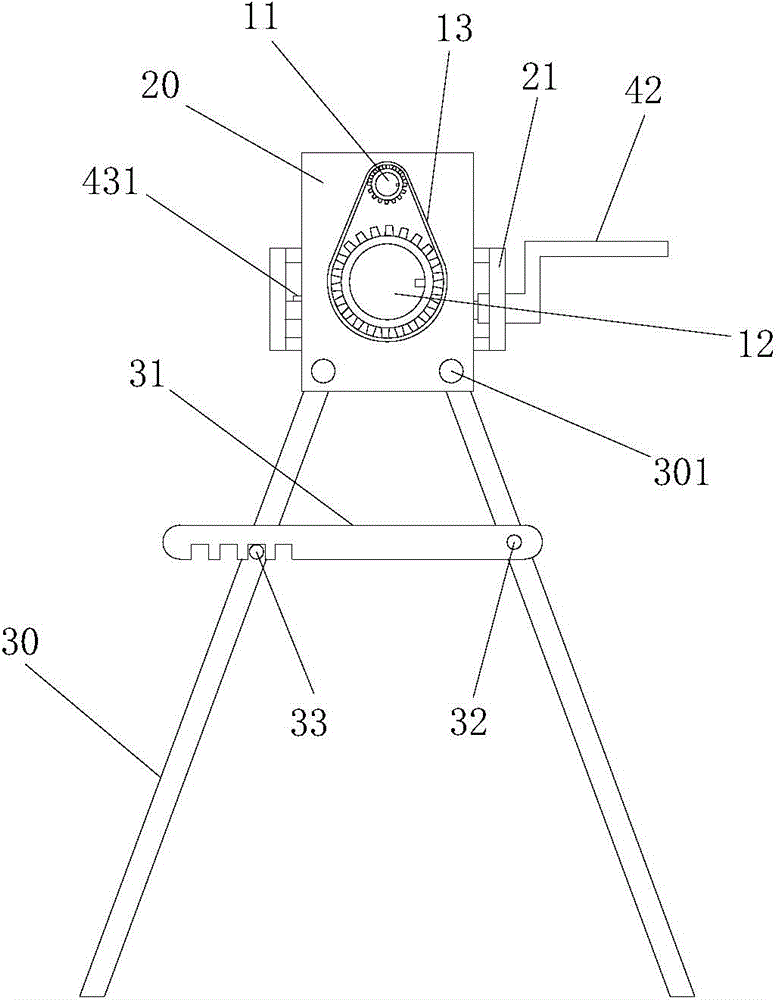

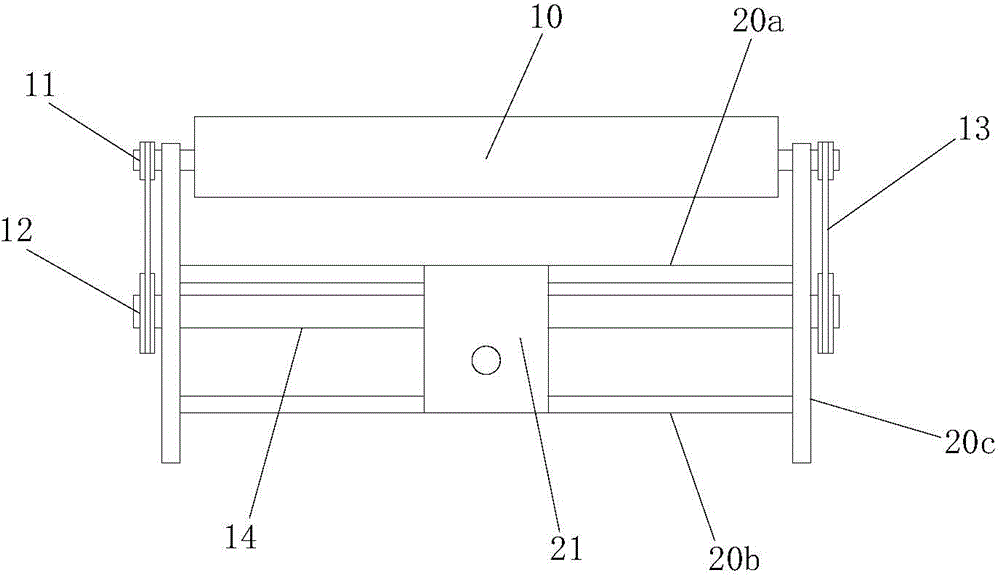

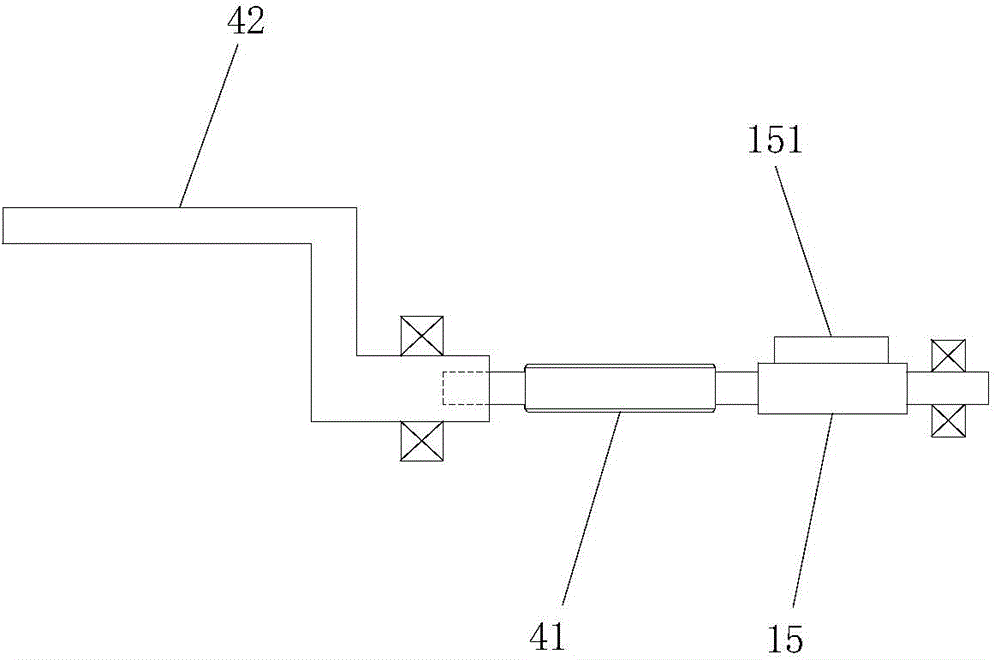

[0018] The technical scheme adopted by the present invention is as follows figure 1 , 2 , 3, 4, and 5, a safety cradle for construction engineering includes a support frame and a rotating drum 10 rotatably installed on the support frame, the rotating drum 10 is connected with the driving mechanism, and a safety rope is wound on the rotating drum 10 , one end of the safety rope is provided with a safety hook, and the support frame includes a mounting seat 20 for mounting the drum 10 and first and second supporting feet 30 for supporting the mounting seat 20. The upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com