Bogie frame structure for traveling system of paver

The technology of a traveling system and a trolley frame is applied in the field of road machinery and equipment, and can solve the problems of inconsistent machining datums of the mounting plate and the mounting plate hole on the side of the body, difficulty in assembling the trolley frame and the paver frame, and the assembling of the trolley frame. There are many problems such as welding parts, so as to achieve the effect of easy guarantee of welding quality, convenient assembly and welding, and reasonable and beautiful layout of hydraulic oil pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

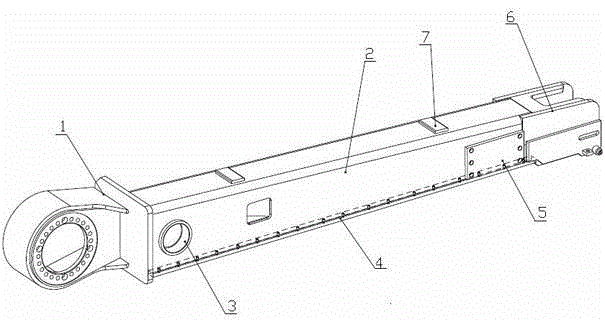

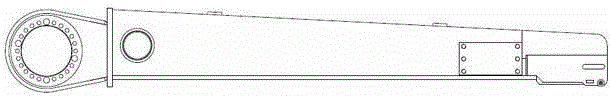

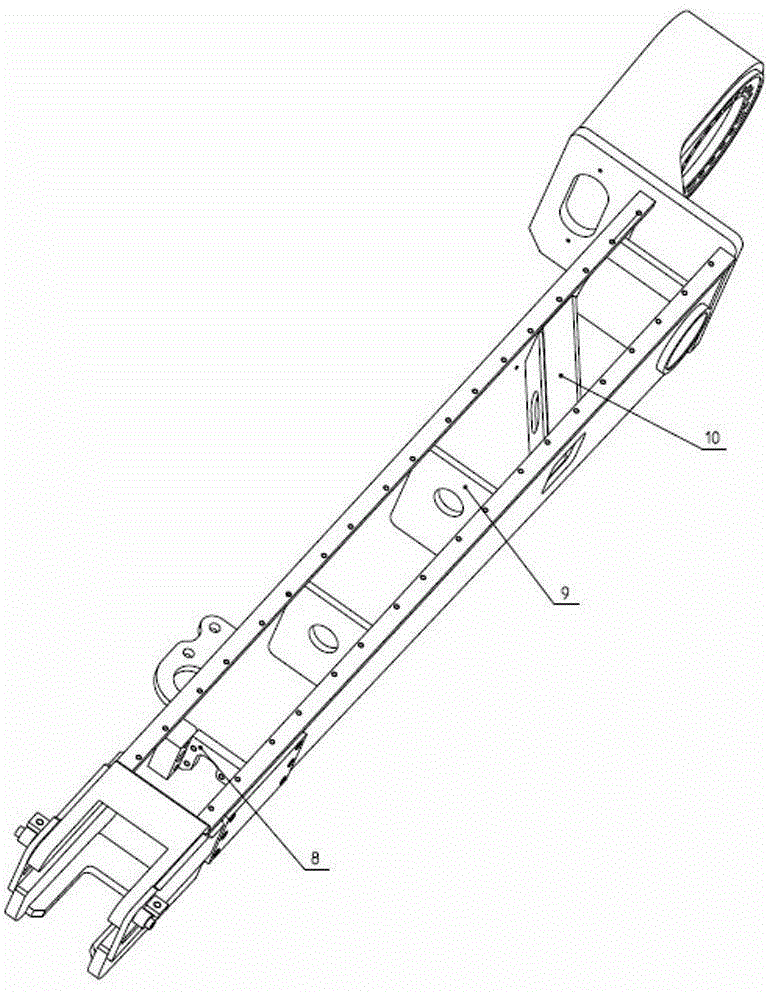

[0022] see Figure 1~6 , the present invention relates to a trolley frame structure for a paver walking system, the structure includes a box bending plate 2, the box bending plate 2 is an inverted groove structure, and the box bending plate 2 The top surface of the box is set along its length as an inclined plane, one end of the box bending plate 2 is connected with the reducer mounting seat 1, and the other end is connected with the guide wheel mounting seat 6, and the speed reducer mounting seat 1 and the box bending plate 2 The connection is located at the high position of the top slope of the box bending plate 2, and the connection between the guide wheel mounting seat 6 and the box bending plate 2 is located at the low position of the top slope of the box bending plate 2, and the box is set in an inverted groove shape. Bottoms of the two side plates of the body curved plate 2 are equipped with strip-shaped bottom plates 4; the top slope of the box body curved plate 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com