Front traction device for low-speed motor tractor

A front traction and tractor technology, which is applied to traction connectors, vehicle components, transportation and packaging, etc., can solve the problems of small output and increase production costs, and achieve the effect of increasing costs, saving costs and realizing the traction function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

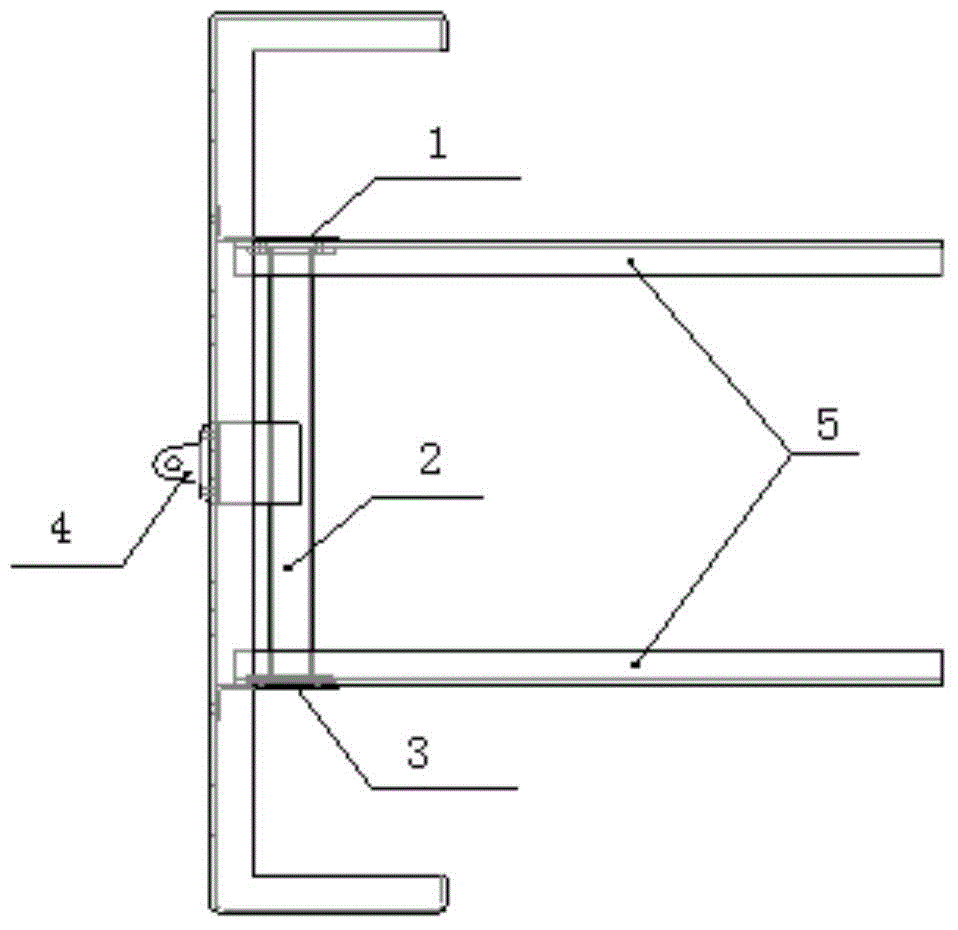

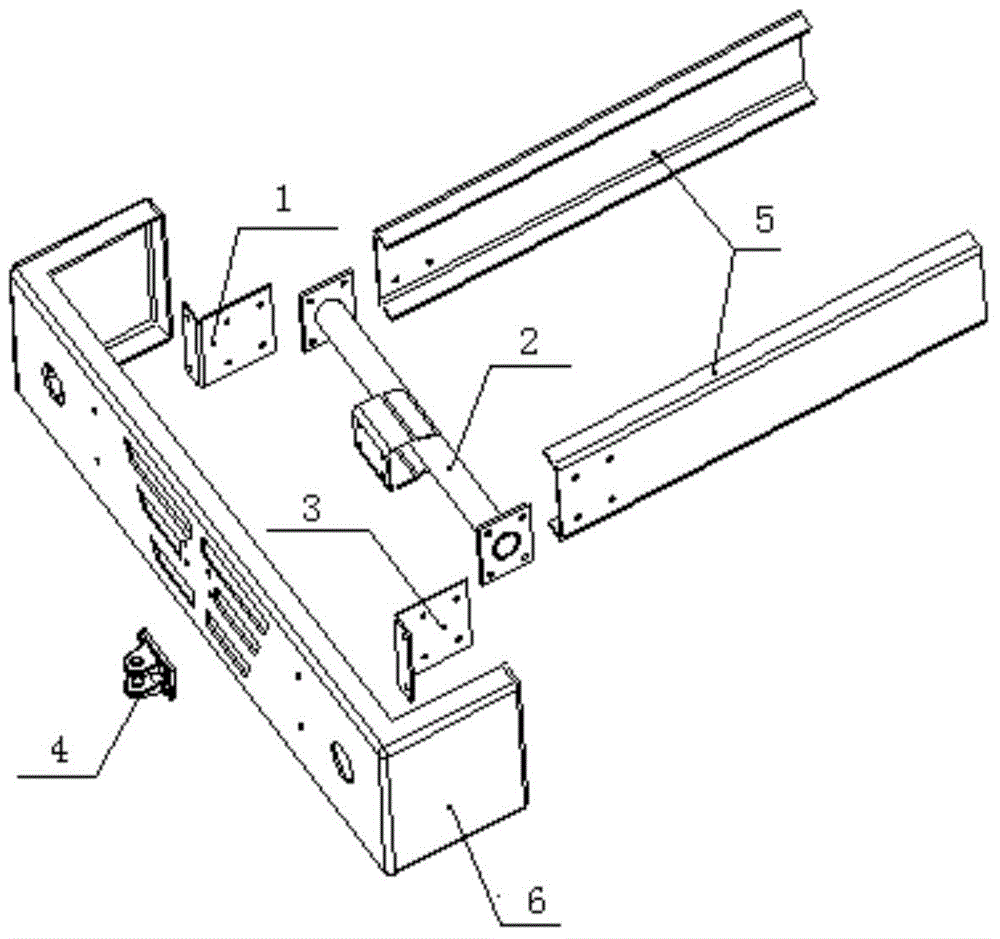

[0019] Depend on figure 1 with figure 2 It can be seen that a front traction device for a low-speed tractor includes a front traction lug assembly 4, a bumper 6, a fixed beam 2 and a vehicle frame assembly 5, wherein the front traction lug assembly 4 is installed on the bumper 6 At the front end, the fixed beam 2 is installed at the rear end of the bumper 6 , and the vehicle frame assembly 5 is installed at the rear end of the bumper 6 through the fixed beam 2 .

[0020] The front traction device also includes a bumper bracket assembly for fixing the fixed beam 2 and the vehicle frame assembly 5, and the bumper bracket assembly includes a first bumper bracket 1 and a first bumper bracket respectively located at the left and right ends of the fixed beam 2. Second bumper bracket 3. The first bumper bracket 1 and the second bumper bracket 3 are installed on the bumper 6 .

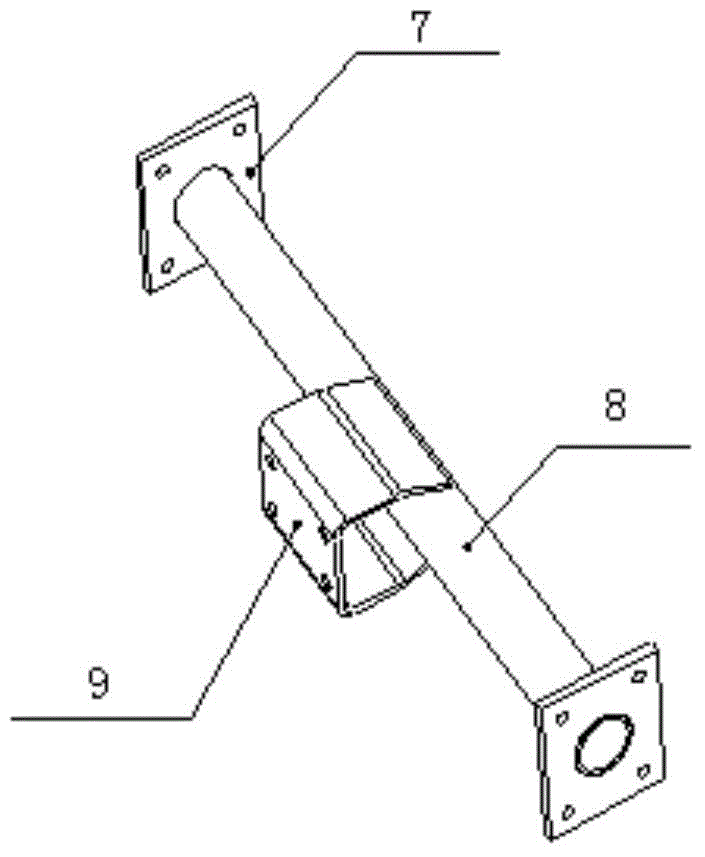

[0021] The fixed beam 2 includes a tubular beam 8 , a first support 7 and a second support located at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com