A material cutting mechanism

A material and cutting technology, applied in the field of material cutting mechanism, can solve the problems of high labor cost, low production efficiency, small size of material, etc., to reduce labor intensity, improve production efficiency, and high cutting precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

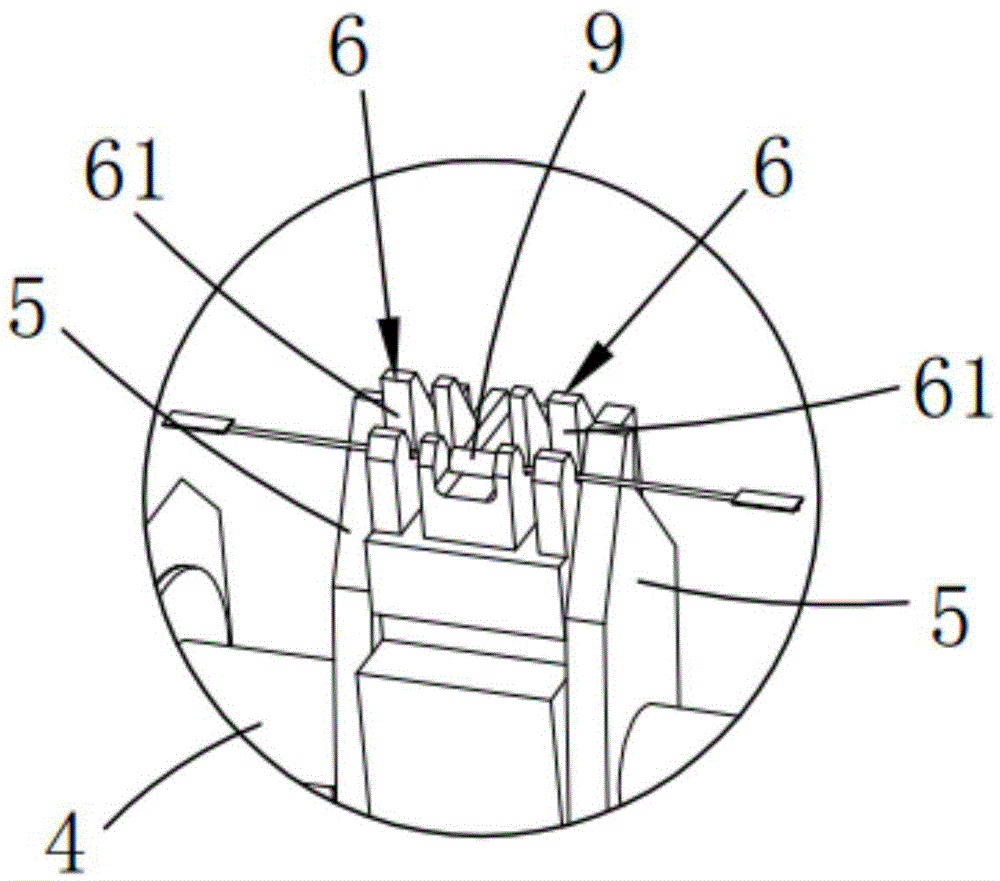

[0019] like figure 1 As shown, a material cutting mechanism includes a support mechanism 1, a pulling mechanism 2, a connecting rod 3, a rotating shaft 4, a cutting knife mold a5 and a cutting knife mold b6, and a support mechanism 1 is horizontally provided plate 7, and the lifting mechanism 2 is vertically fixed on the end of the support plate 7, and placed on the front side of the support mechanism 1; the upper end surface of the support mechanism 1 is provided with a fixing seat 11, and the left and right sides of the fixing seat 11 are respectively A support 8 is vertically provided, and the support 8 is provided with a shaft hole adapted to the rotating shaft 4, and the rotating shaft 4 is rotated and arranged on the support 8; the cutting die a5 and the cutting die b6 are respectively set On the rotating shaft 4, the cutting knife mold b6 is vertically fixed on the fixed seat 11, and the cutting knife mold a5 is placed on the left and right sides of the cutting knife mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com