Inner hole sleeve pulling device

An inner hole sleeve and puller technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency, time-consuming and laborious, and difficult disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

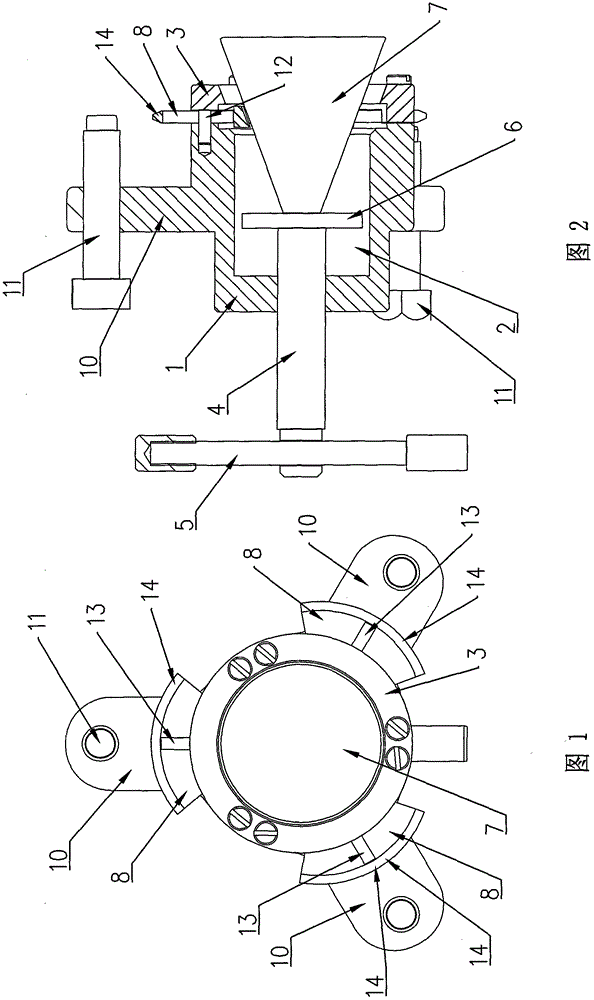

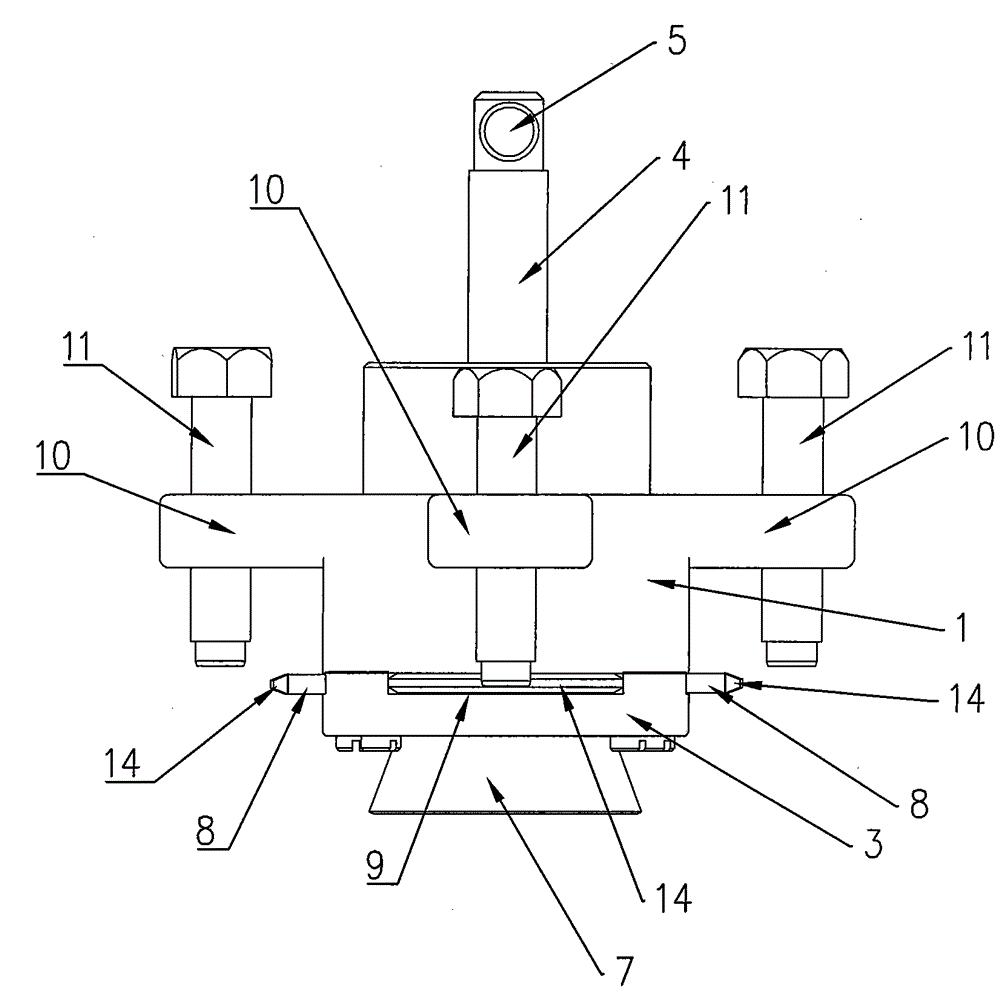

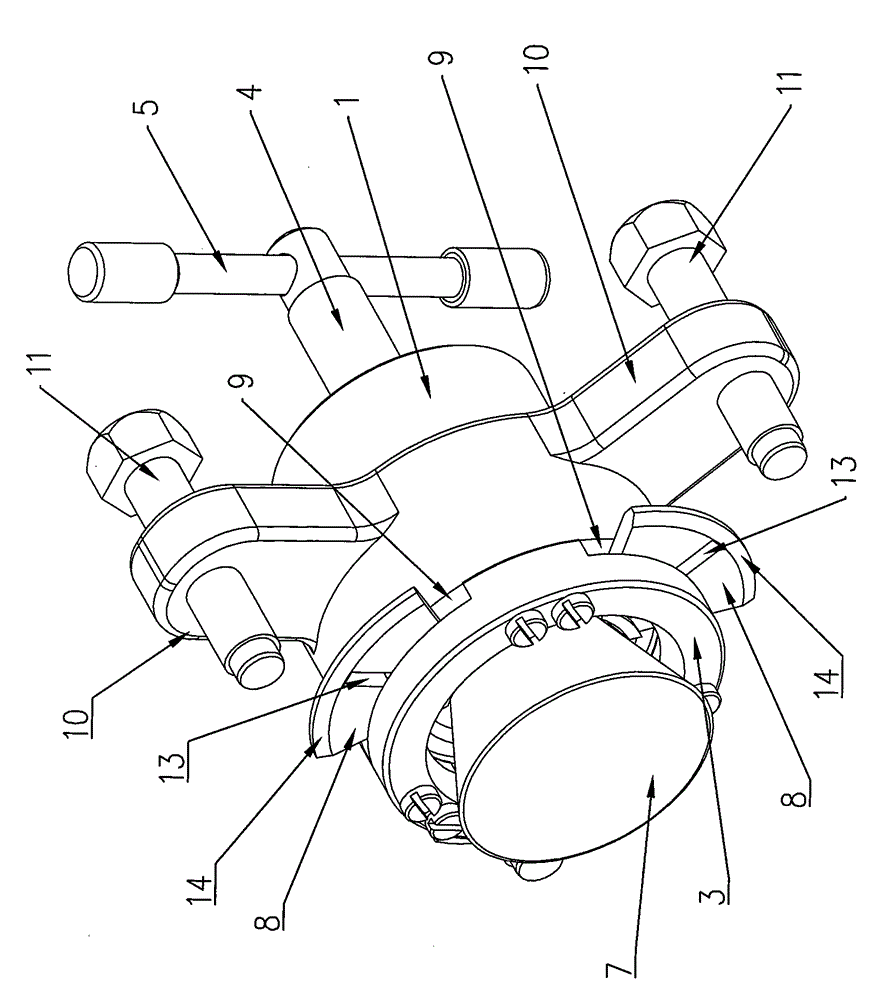

[0019] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the inner hole sleeve pulling device of the present invention includes a cylindrical lifting base 1, the axis of the lifting base 1 is located in the front and rear horizontal direction, and the middle part of the front end face of the lifting base 1 is provided with a cylindrical shape. Cavity 2, the middle part of the outer wall of the lifting base 1 is fixedly connected to the inner end of a plurality of lifting plates 10, and the plurality of lifting plates 10 are evenly distributed around the circumferential surface of the lifting base 1, and each lifting plate The plate surfaces of 10 extend outward along the radial direction of the cylindrical lifting base 1, and each lifting plate 10 is respectively screwed with lifting bolts 11 along the front and rear horizontal directions;

[0020] An annular gland 3 is fixed on the forward end surface of the lifting base 1, and a plurality of guide grooves 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com