Method for indirectly applying printing liquid to a printing substrate

A printing material and liquid technology, applied in printing, copying/marking methods, printing devices, etc., can solve the problems of printing ink detachment and transmission, and achieve the effect of improving detachment, strong fluidity, and detachment improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

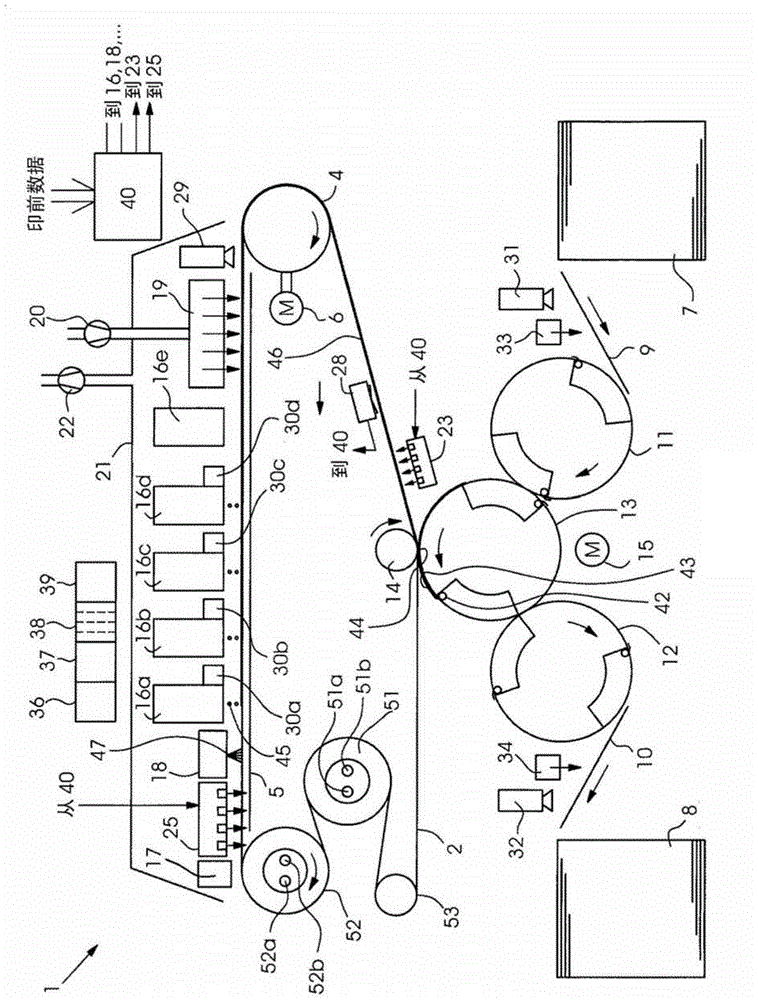

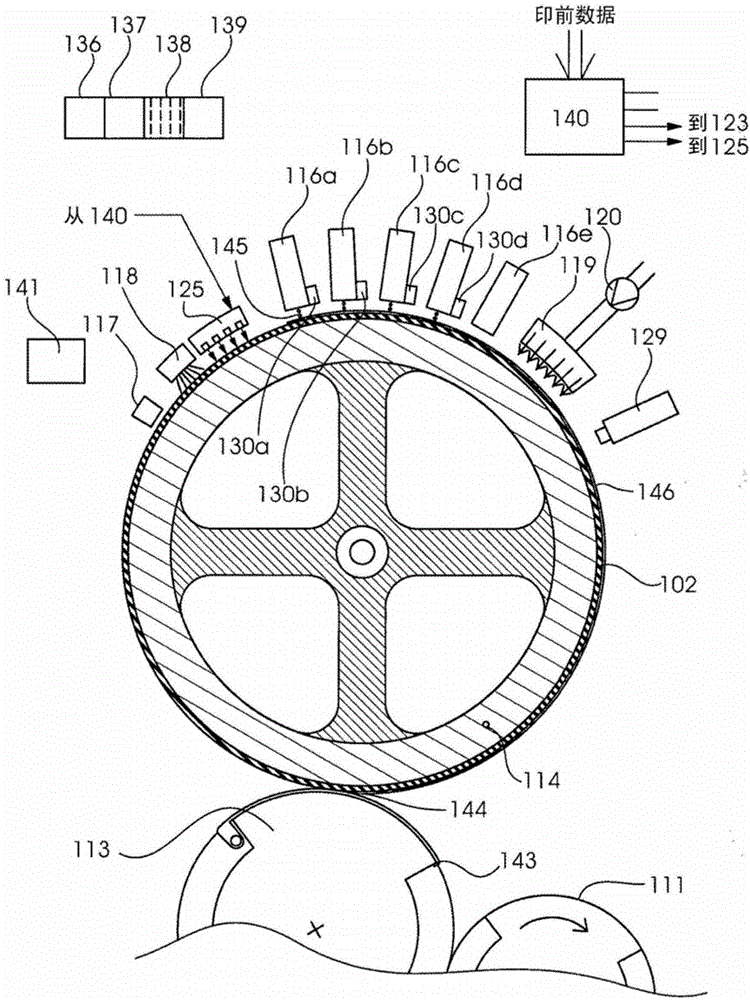

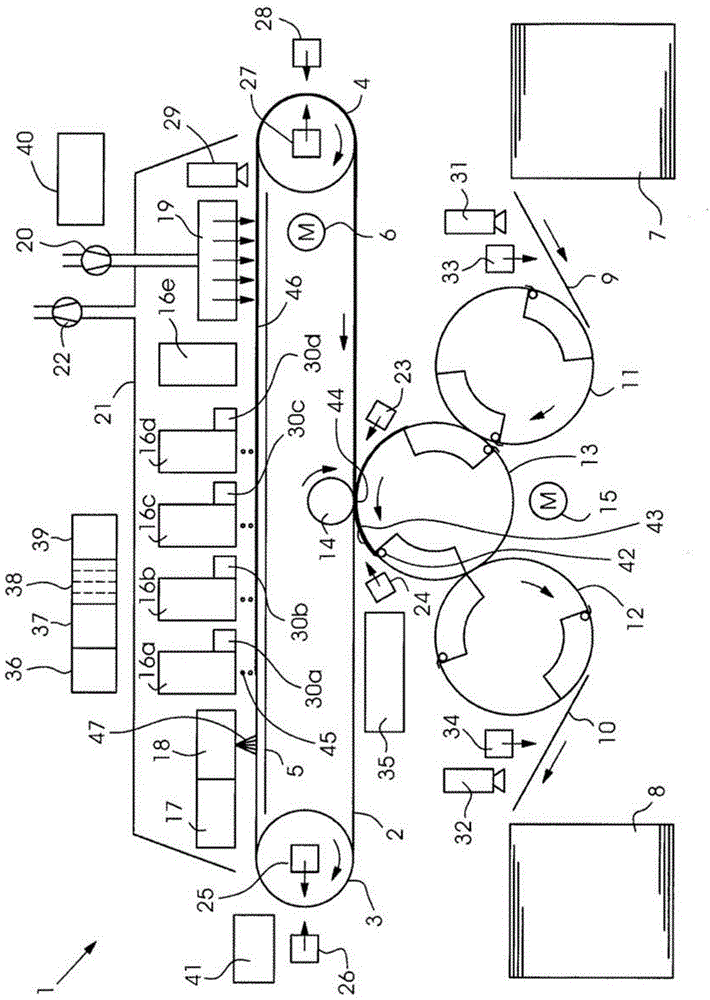

[0128] A rubber belt is provided as intermediate carrier 2 , the structure of which is preferably comparable to that of offset blankets. An approximately 2 μm thick layer of TPnB (tripropylene glycol n-butyl ether, eg product tripropylene glycol butyl ether TPnB) is applied to the rubber belt by means of spray beams 18 . Water-based and binder-based inks are applied last.

example 2

[0130] A Teflon-coated conveyor belt is provided as intermediate carrier 2 . An approximately 4 μm thick layer of DPM is applied thereon as a separating layer (dipropylene glycol methyl ether, eg the product dipropylene glycol methyl ether DPM). The application can be effected by means of a roller system, in particular similar to an offset dampening device. A thin dispersed varnish layer of approximately 0.1 to approximately 1 μm is then applied, which is dried and then forms a skin on the DPM. A separate dryer can be provided for this purpose, in the figure 1 is not shown but can be placed directly behind the application device 18 . Water-based and binder-based inks, in particular so-called latex inks, are applied last.

example 3

[0132] A belt or a roller cover is used as intermediate carrier 2, the material of which is comparable to known offset blankets. A thin oil layer of approximately 0.1 to approximately 1 μm, in particular a vegetable oil such as sunflower oil, is applied as a separating layer to the intermediate carrier. Finally the organic solvent based ink is applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com