Automatic screw tightening control method and device

A control method and screw technology, which can be applied to portable mobile devices, screwdrivers, power tools, etc., can solve the problems of inability to obtain operation effects and operation efficiency, and achieve the effect of reliable confirmation and judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

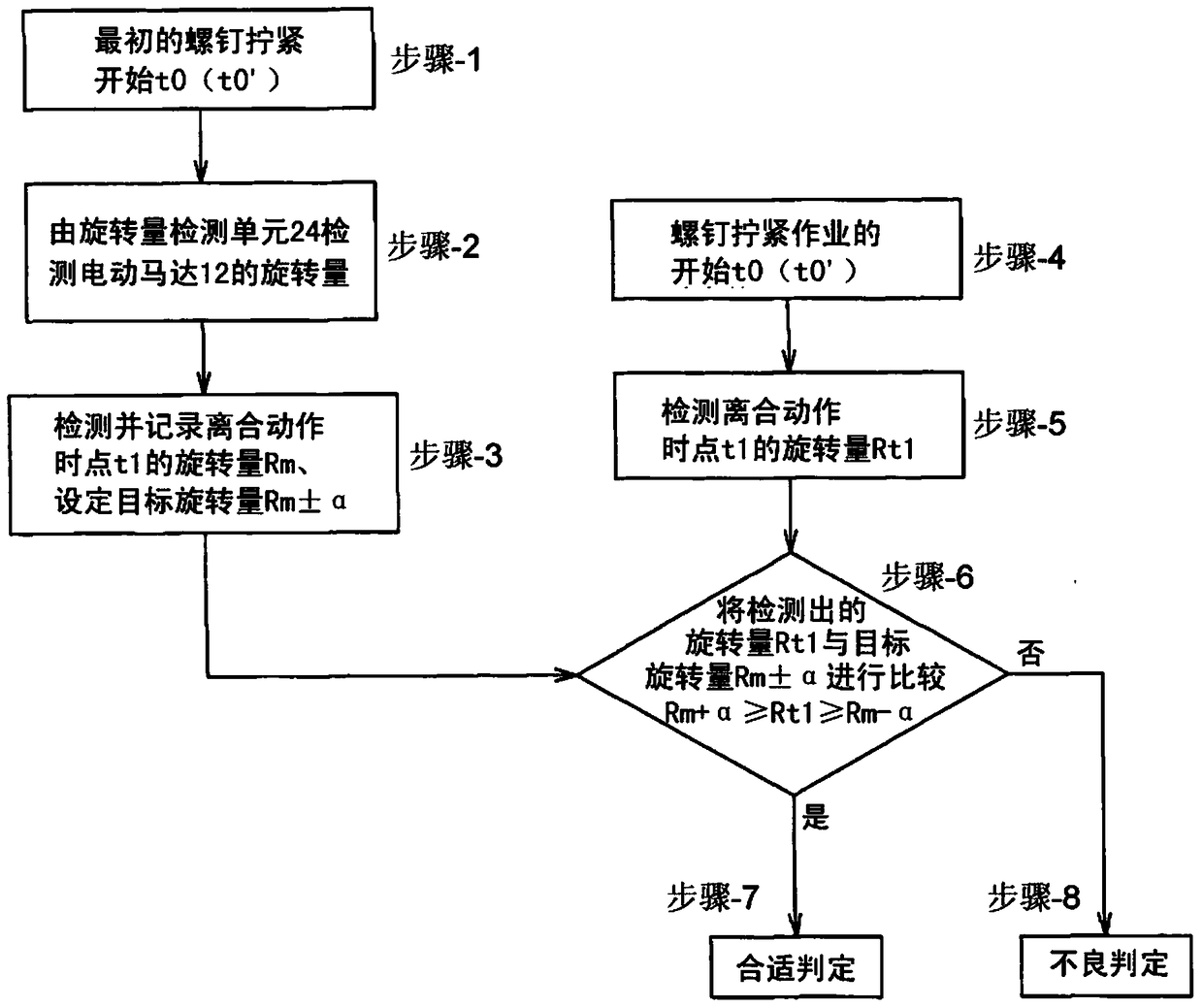

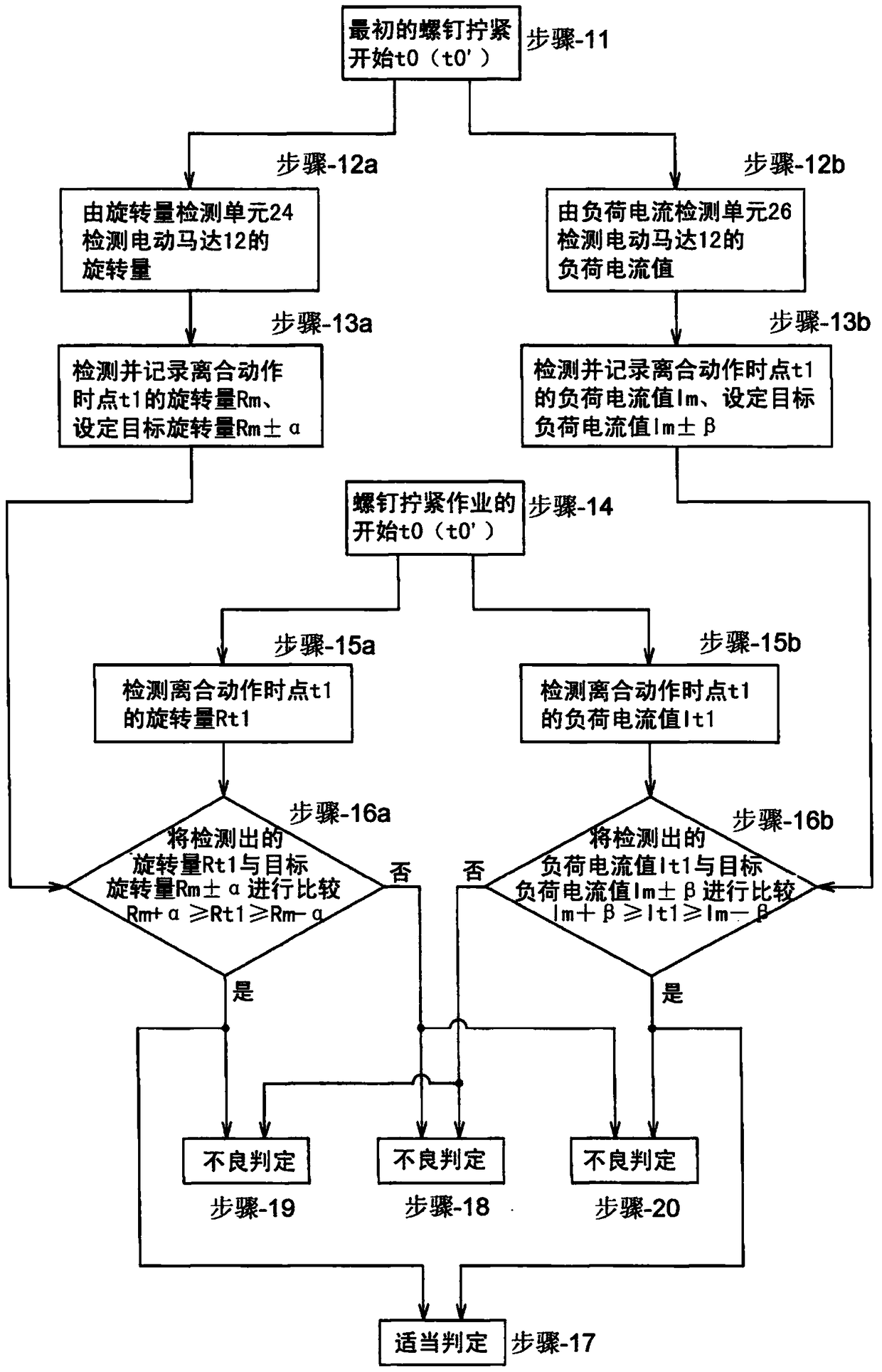

[0070] Next, regarding an embodiment of the automatic screw tightening control method of the present invention, the relationship with the device implementing the method will be described in detail below with reference to the drawings.

[0071] [ Structure of automatic screw tightening control device (1) ]

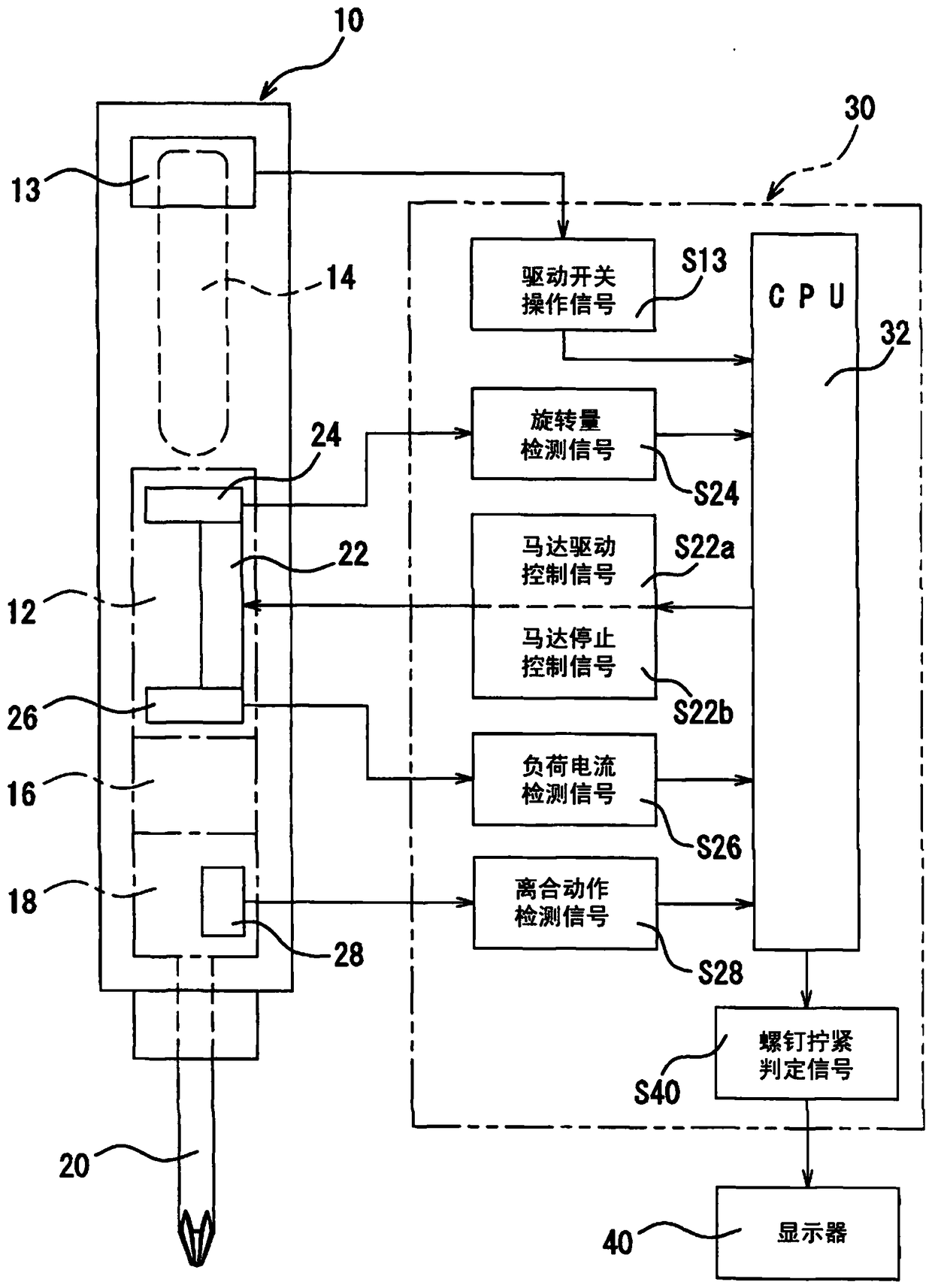

[0072] figure 1 It is a schematic configuration explanatory diagram showing an embodiment of an apparatus for implementing the automatic screw tightening control method of the present invention. That is, in figure 1Among them, reference numeral 10 represents an electric screwdriver. In the grip portion of the electric screwdriver 10, an electric motor 12, a drive switch 13 for driving the electric motor 12, and a drive output shaft of the electric motor 12 (not shown in the figure) are respectively built-in. Shown) combined deceleration mechanism 16 and clutch mechanism 18, through which the screwdriver bit 20 is combined through the clutch mechanism 18.

[0073] The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com