Automatic transfer switch transmission mechanism

A technology of automatic transfer switch and transmission mechanism, which is applied to the power device, electric switch, contact operating mechanism and other directions inside the switch, which can solve the problems of sticking of the push rod, complicated installation and low use efficiency, and improve the reliability of operation. , Improve work efficiency, simple and convenient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

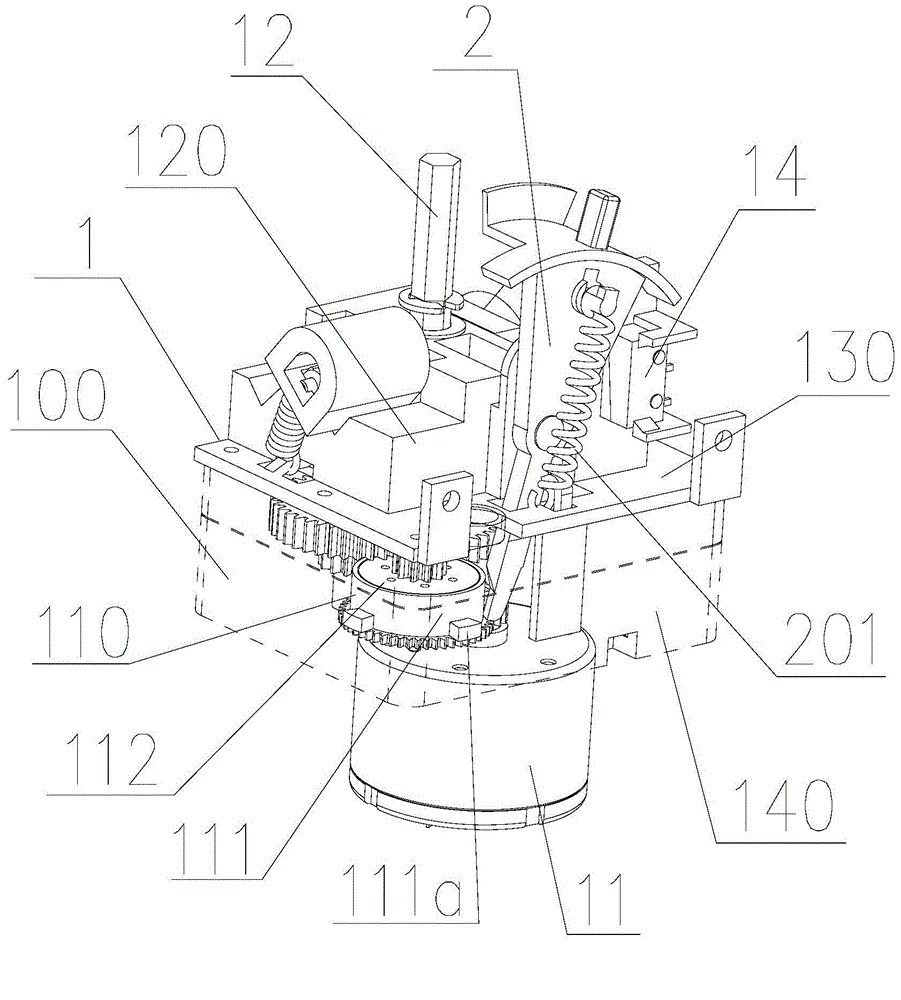

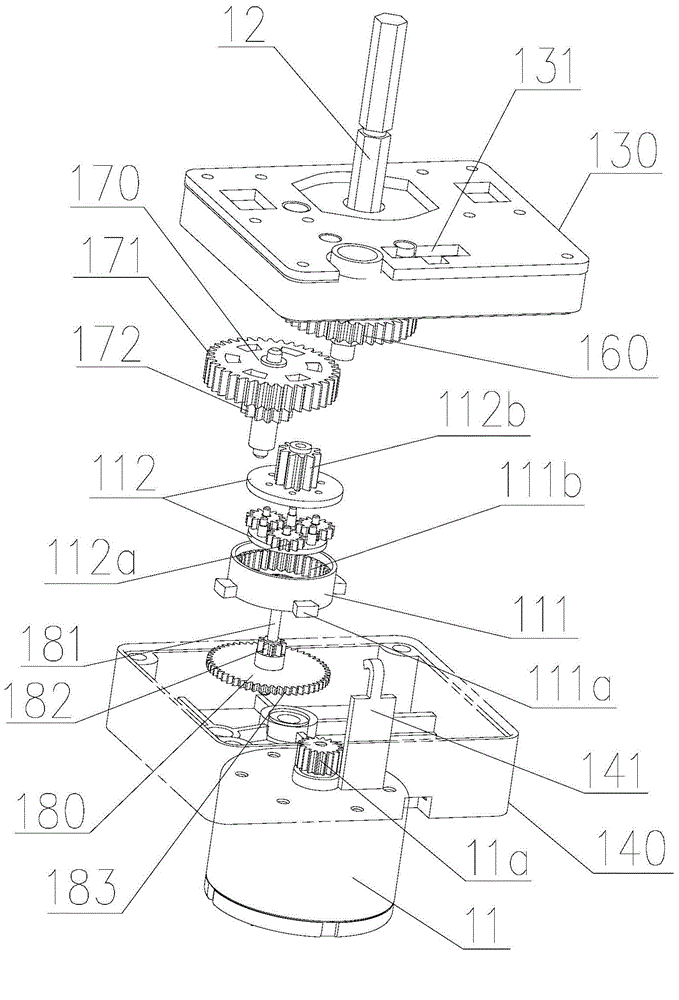

[0024] The following is attached Figures 1 to 8 The embodiment of the present invention is given to further illustrate the specific implementation of the transmission mechanism of the automatic transfer switch of the present invention. The transmission mechanism of the automatic transfer switch of the present invention is not limited to the description of the following embodiments.

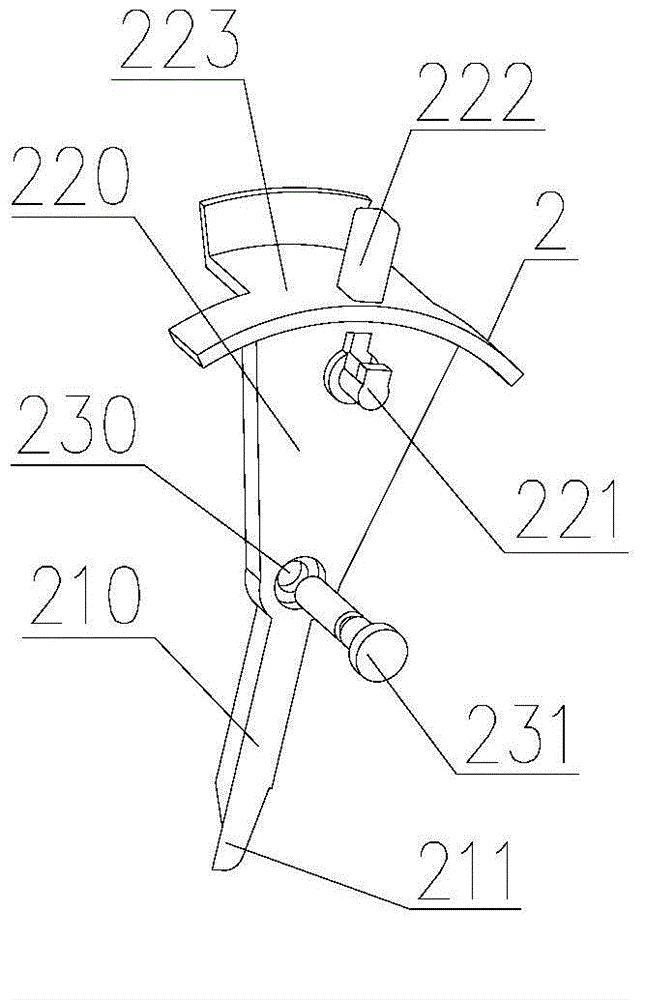

[0025] The automatic transfer switch of the present invention comprises the transmission mechanism 1 fixedly installed on the base plate 300, the executive switch 3 and the controller 15, such as Figure 8 As shown, execution switches 3 are respectively installed on both sides of the transmission mechanism 1 so that the transmission mechanism 1 can be mechanically coupled with two execution switches 3 nearby. The execution switch 3 includes a push rod 301 that can drive the execution switch 3 to act. The above-mentioned push rod is connected with the rocker arm 12c of the transmission mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com