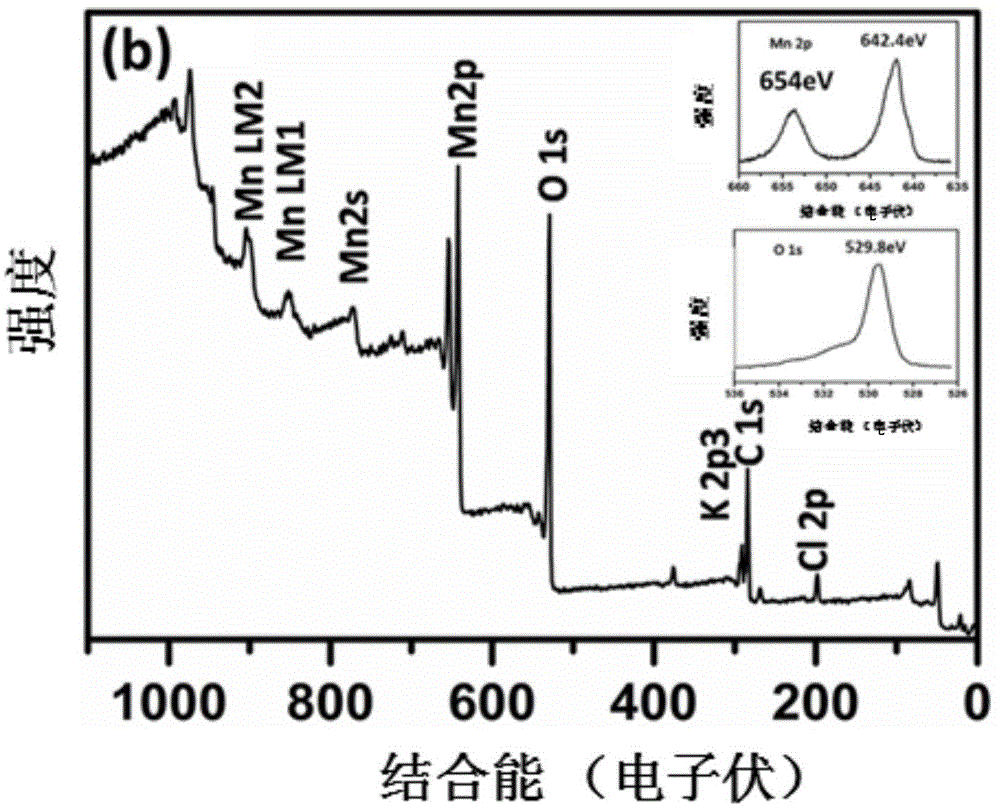

Manganese dioxide dendritic nano array electrode material and preparation method

A manganese dioxide, electrode material technology, applied in nanotechnology, nanotechnology, hybrid capacitor electrodes, etc., can solve the problems of coherent growth without dendritic structure, and achieve excellent high current charge and discharge capacity, high orderliness , the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

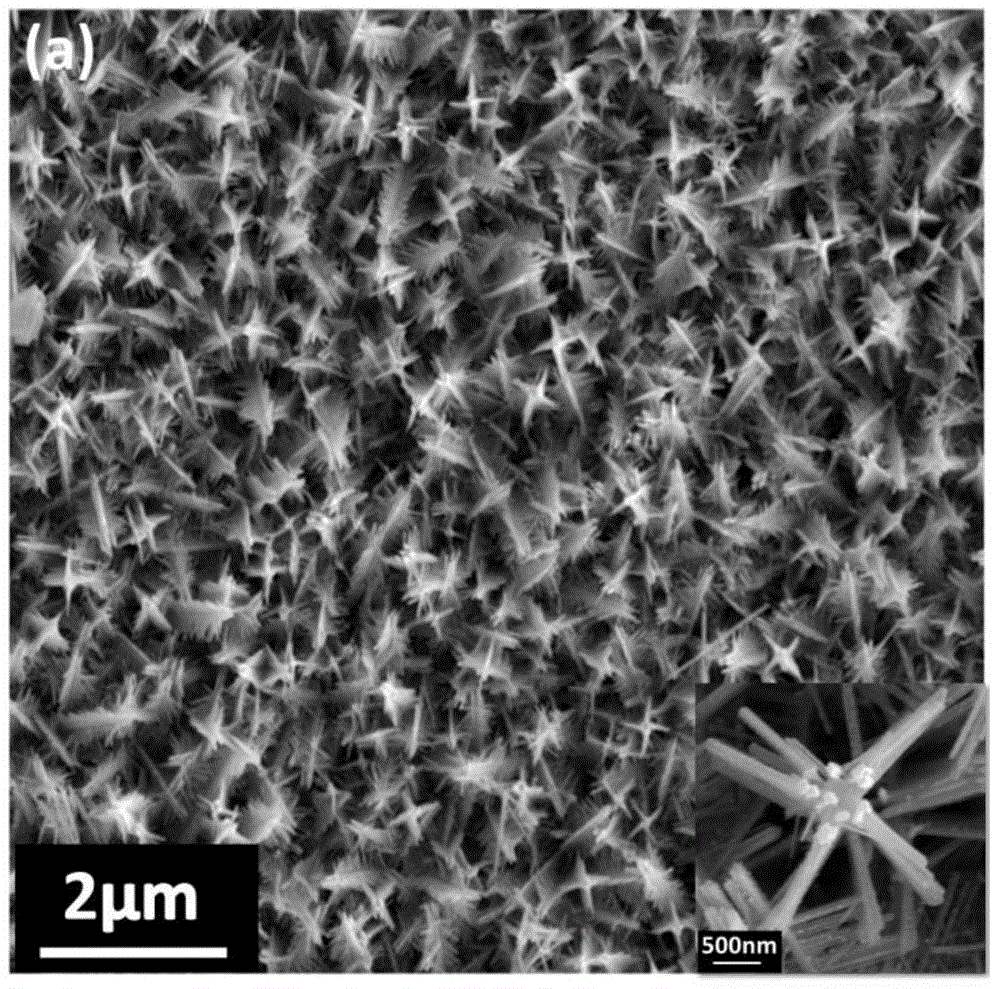

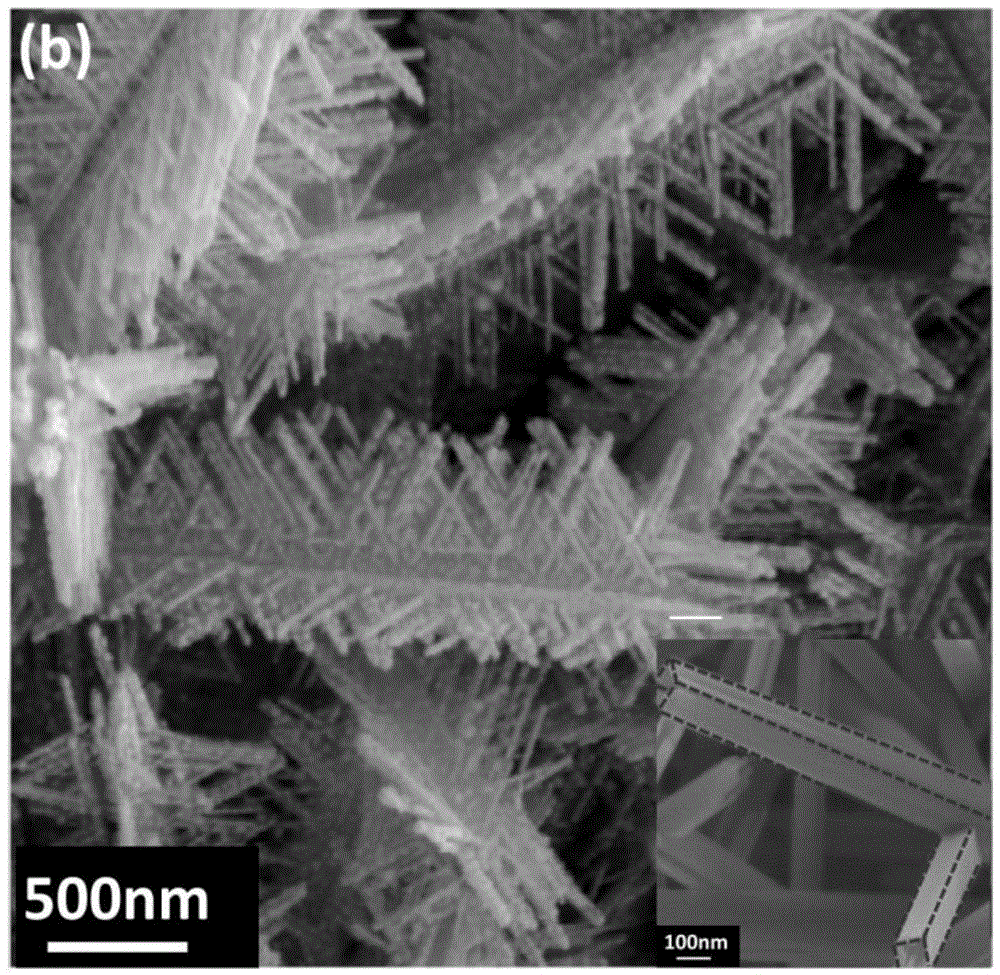

Embodiment 1

[0054] This embodiment provides a method for preparing manganese dioxide dendritic nano-array electrode material, which specifically includes the following steps:

[0055] Step 1, the first step of hydrothermal method:

[0056] Add 1cm×3cm single-throw silicon wafers in turn into a 45mL hydrothermal kettle, add 0.396g potassium permanganate, 0.58mL 38% concentrated hydrochloric acid and about 33mL deionized water into the hydrothermal kettle, so that potassium permanganate and hydrochloric acid The molar ratio of the hydrochloric acid is 1:4, and the concentration of hydrochloric acid is 2 / 7mol / L; the hydrothermal kettle is placed in an oven, and the temperature is adjusted to 140°C for primary crystal growth, and the primary growth time is 12 hours; primary growth Cool down after completion, take out the single-throw silicon wafer; centrifuge the solution in the hydrothermal kettle three times at a centrifugal speed of 5000r / min, and dry to obtain a single-throw silicon wafer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com