Mobile blanking frame of automatic receiving system

A blanking and automatic technology, applied in the field of mobile blanking racks, can solve the problems of time-consuming and laborious, waste of copper materials, insufficient pressure of the flat winding head, etc., to achieve the effect of expanding the range of processing technology, reducing coil deformation, and improving the efficiency of flat winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

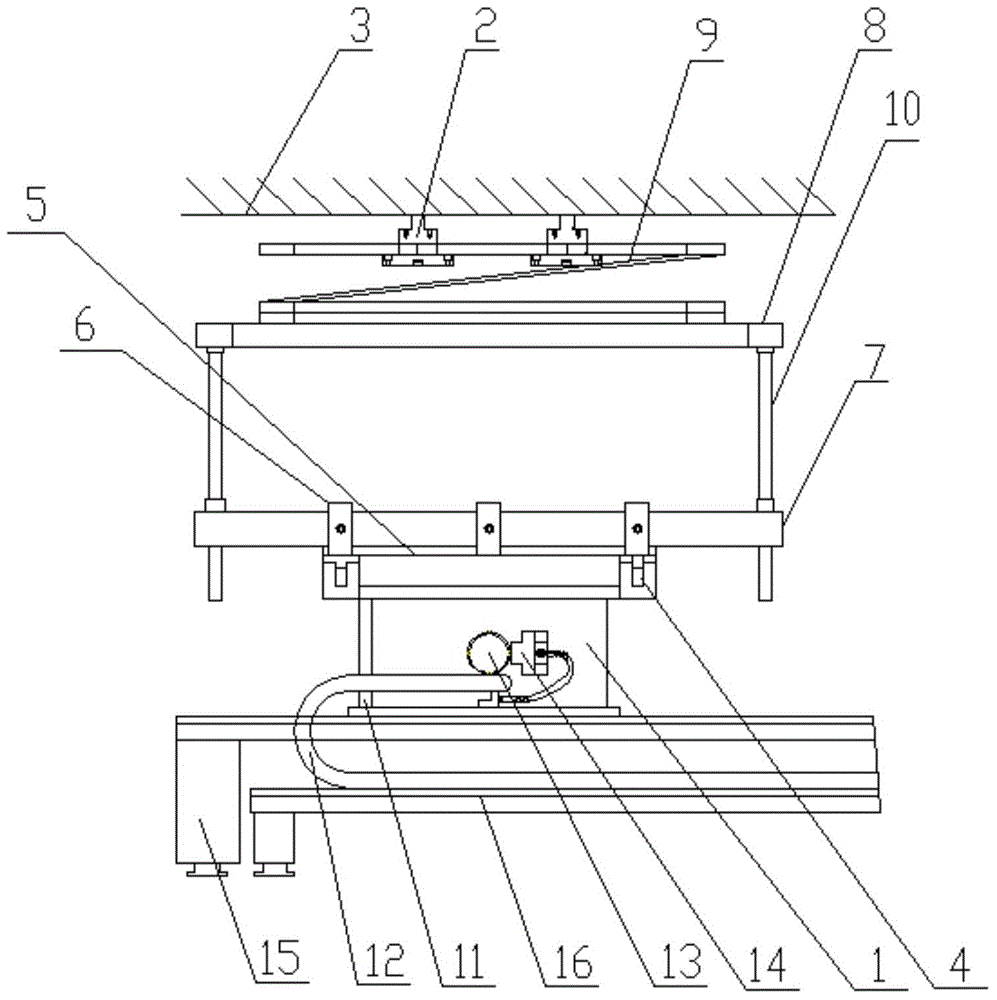

[0016] Such as figure 1 As shown, a mobile blanking frame of an automatic material receiving system of the present invention includes a mounting base 1, a flat winding head 2, a working beam 3 and a vertical support 4, and the working beam 3 is provided with a flat winding head 2, A mounting seat 1 is provided below the flat winding head 2, a vertical support 4 is provided on the mounting seat 1, a slideway 5 is provided on the vertical support 4, and a sliding U-shaped slideway 5 is provided on the slideway 5. Fixture support 6, the sliding U-shaped fixture support 6 is provided with a double-sided guide rail 7, a material-receiving frame 8 is arranged above the double-side guide rail 7, and a material-receiving frame 8 is arranged between the flat winding head 2 and the material-receiving frame 8 There is a magnetic pole coil 9, a screw lifting mechanism 10 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com