Spacecraft controlling force layout optimizing method for improving failure reconfigurability

A layout optimization and spacecraft technology, applied in the field of aerospace control, can solve problems such as poor reconfigurability and failure to fully utilize resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

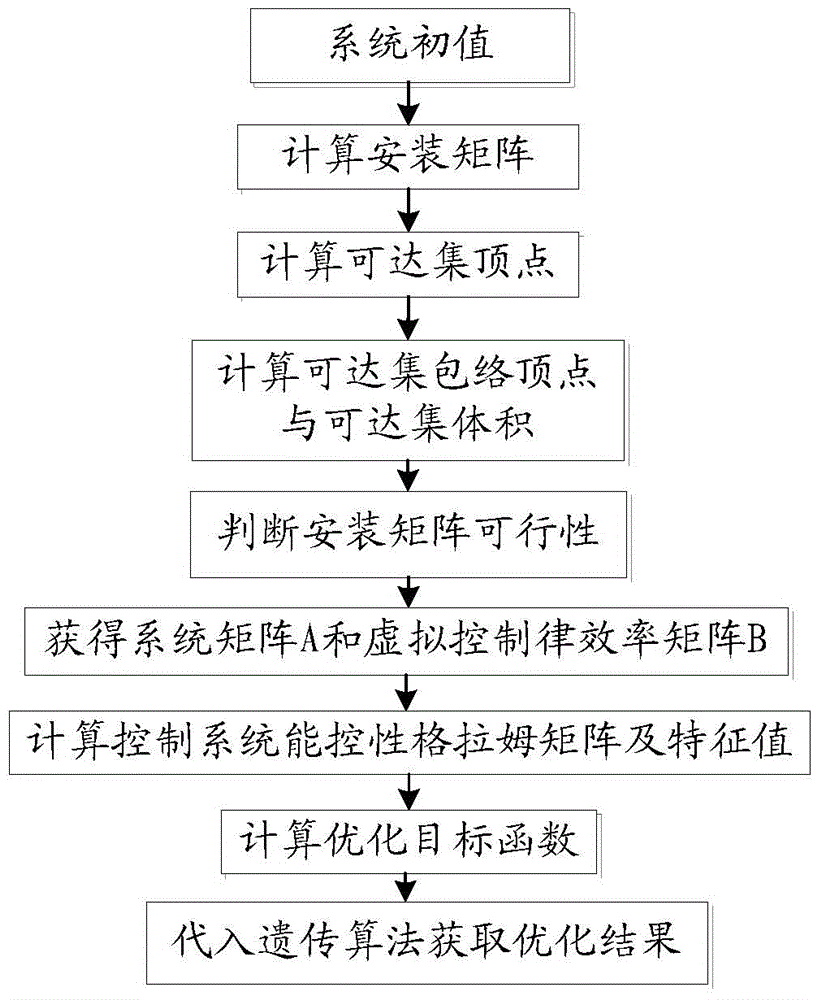

[0026] Such as figure 1 Shown is the flowchart of the method of the present invention.

[0027] Here, it is assumed that there are m thrusters in the spacecraft thruster system, and the number of thrusters to be optimized is p, where p≤m, and both m and p are positive integers. Such as figure 2 As shown, each thruster has two design variables (α i ,β i ), α i and beta i are two mounting angles, i=1,2,3...p. The present invention transforms the reconfigurable design problem into an optimization problem, and the main steps are as follows:

[0028] Step (1): Determine the independent variables and initial values of the optimization problem.

[0029] In the present invention, the independent variable is all (p installation angle pairs to be designed, totally 2p variables) installation angles to be designed, θ=[…α i ,β i …], give the initial value of the simulation. Since the present invention will use the genetic algorithm to iterate later, the initial value can be gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com