A mobile airflow guiding air supply rack for a hot air drying room

A technology of airflow guidance and hot air drying, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of uneven drying of wood stacking, poor sealing of drying room, low efficiency, etc., to improve the operation of personnel. Safety, improving the level of mechanized operation, and the effect of huge economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

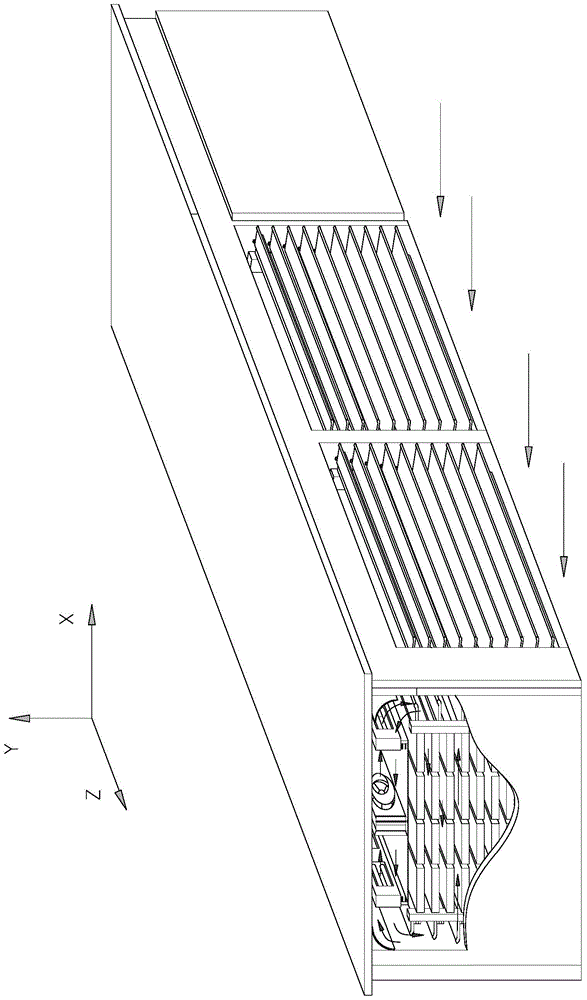

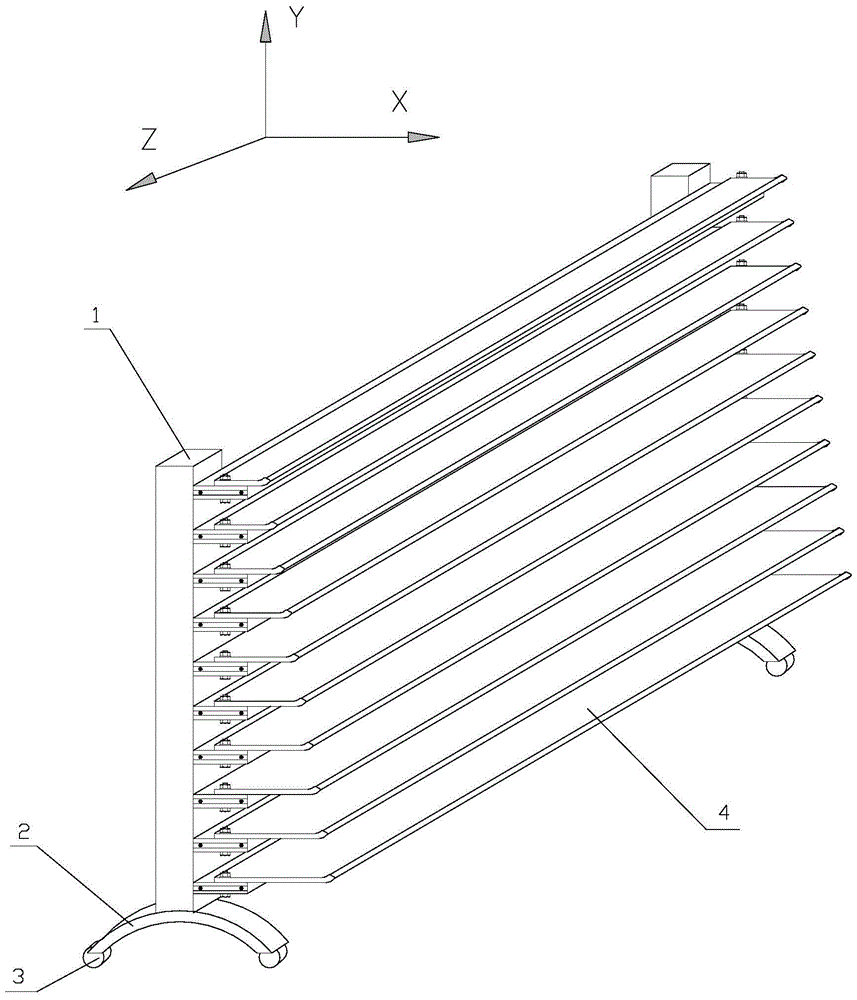

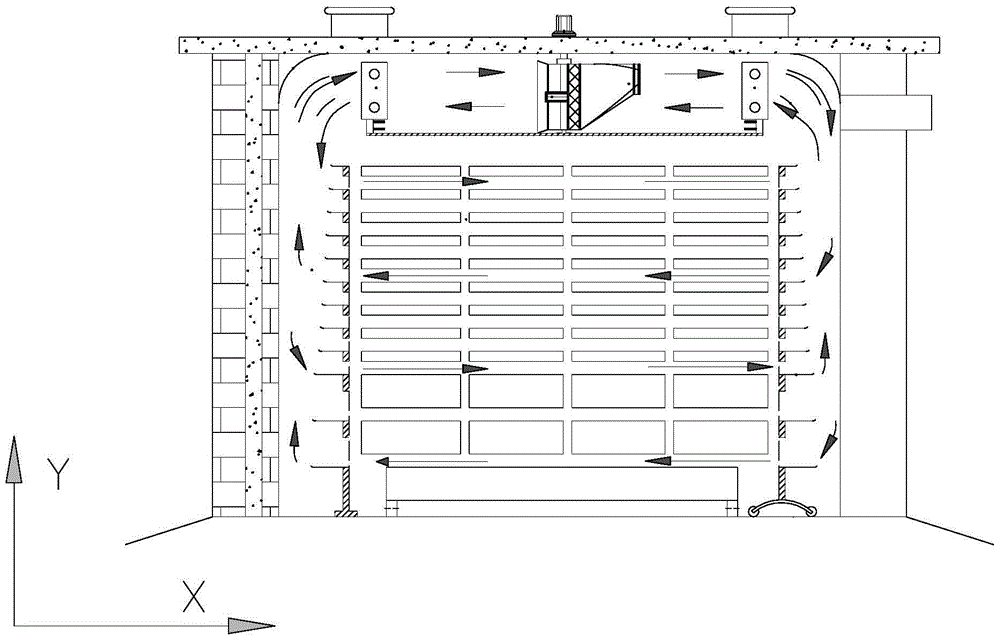

[0039] A mobile airflow guiding air supply rack for a hot air drying room. Let the upward direction of the drying room be Y direction, the width direction be X, and the length direction of the drying room be Z. The stacked plates are pushed into the drying room by the gate along the X direction, and the two exhaust flow guiding air supply racks are respectively arranged on the inner wall side of the drying room and the side close to the gate. The air supply rack is composed of a plurality of single mobile airflow guiding air supply racks arranged along the Z direction;

[0040] The single mobile airflow guide air supply frame is two vertical support frames at both ends, and the middle is composed of several deflector components arranged horizontally;

[0041] The support frame is a Y-shaped steel vertical bar 1, the bottom of which is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com