Self-adjusting lower valve head of crushed coal pressurized gasifier ash lock

A crushed coal pressurized gasification and self-adjusting technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problem of the vulnerability of the lower valve seat, the damage of the contact surface of the lower valve seat, and the inability of the valve head and the valve seat to fit and seal and other issues, to achieve reasonable structural design, improve service life, and ensure tightness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

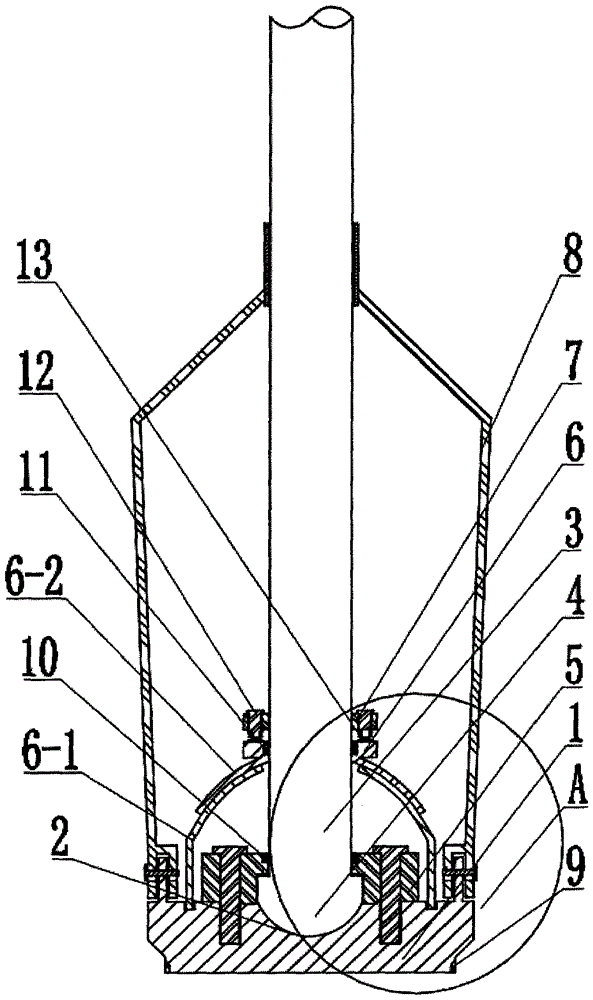

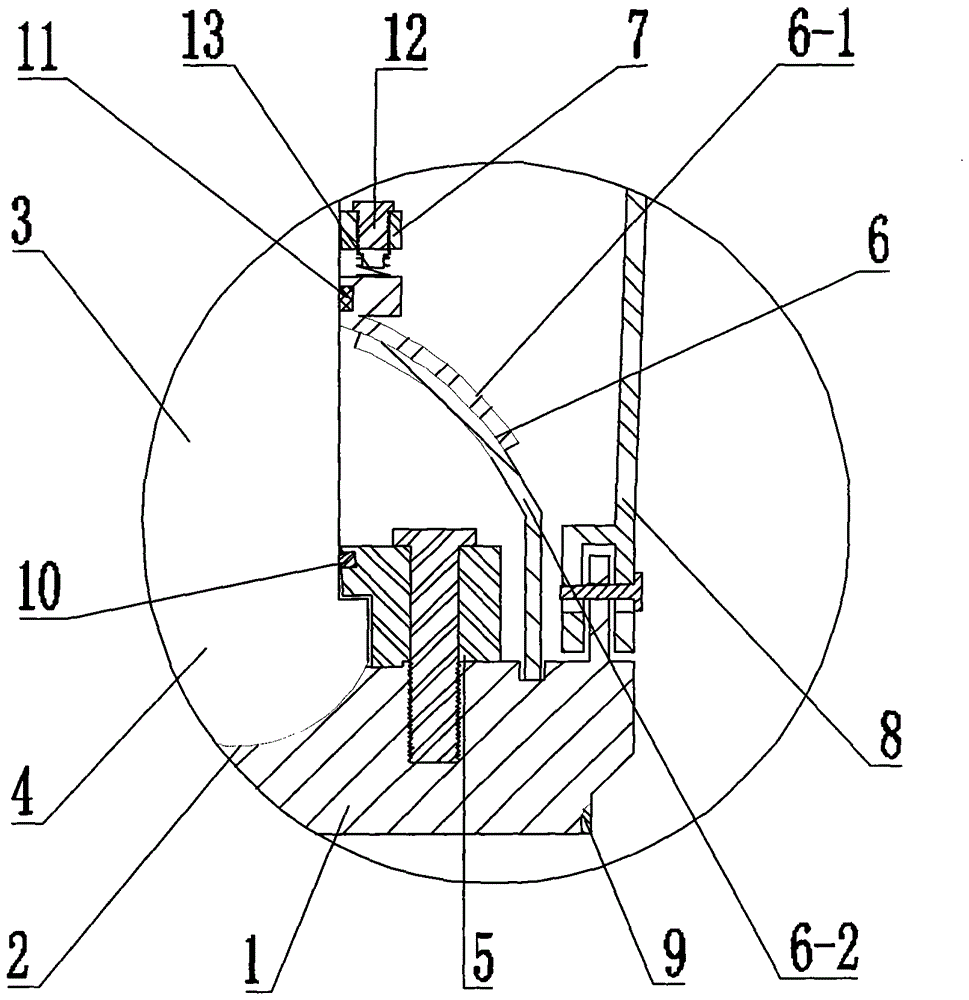

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0016] Such as figure 1 and 2 As shown, the ash lock self-adjusting lower valve head of the crushed coal pressurized gasifier is characterized in that it includes a valve head 1, a concave arc 2 is arranged in the middle of the valve head 1, and a valve stem 3 is embedded in the concave arc 2, The valve stem 3 is set in cooperation with the arc head 4 at the lower end and the concave arc 2. The periphery of the arc head 4 is correspondingly provided with a flange 5, and a pressure cap 6 is arranged on the periphery and above of the flange 5, and a pressure plate is arranged above the pressure cap 6. 7. The outer periphery of the pressure cap 6 and the pressure plate 7 is provided with an ash shield 8 .

[0017] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com