Combined heavy sliding linear guide rail

A linear guide rail and combined technology, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve the problems that the reliability of the impact machine cannot be guaranteed, and the performance index requirements of the horizontal strong impact machine cannot be met, so as to achieve high precision and reliability. Good performance and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

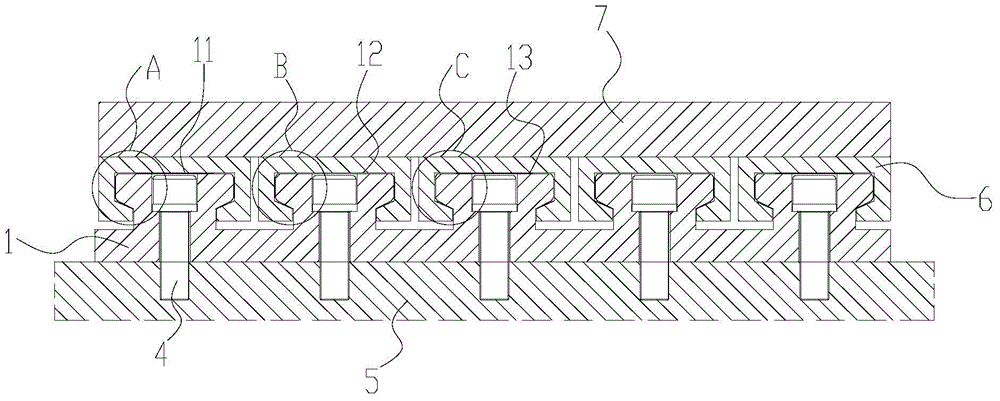

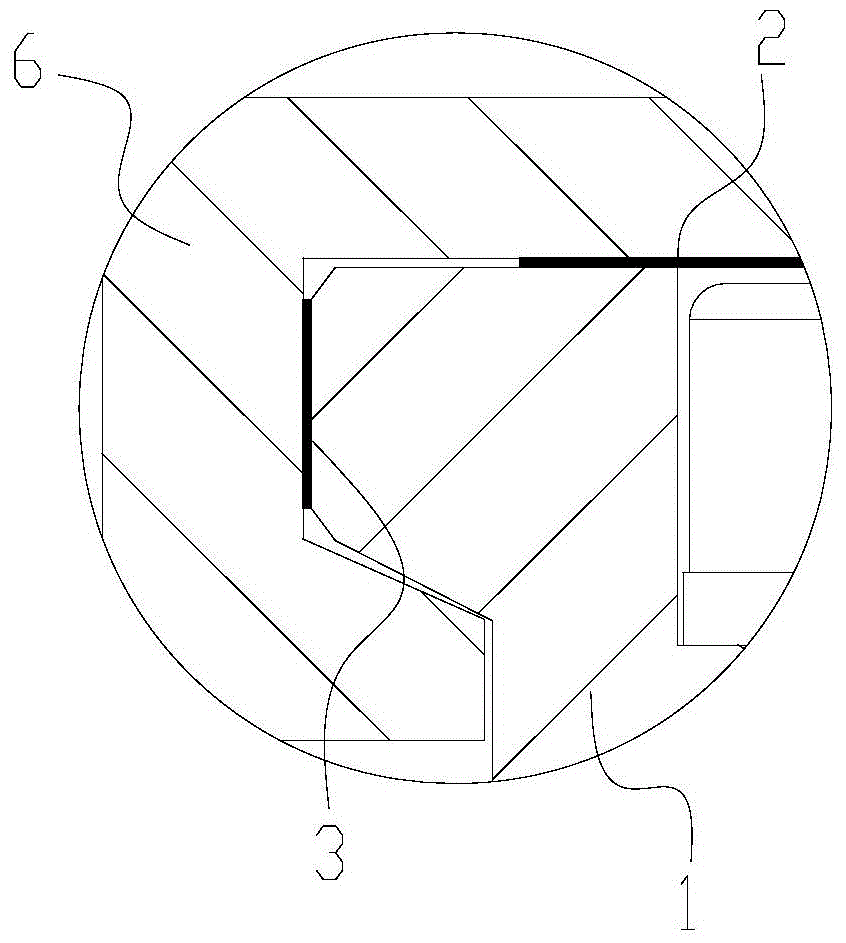

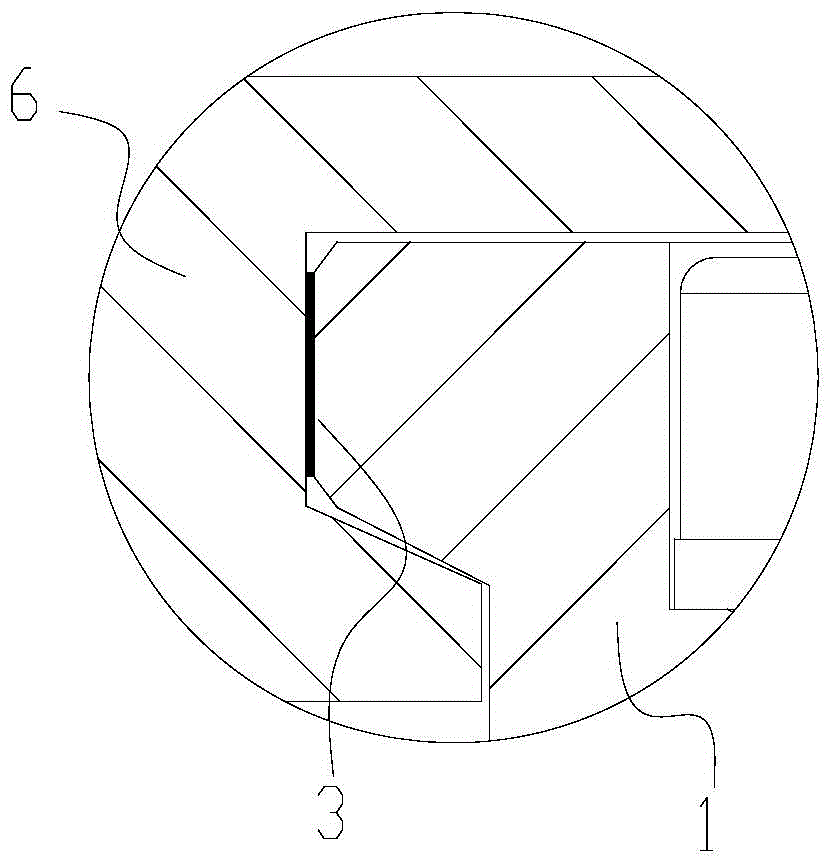

[0036] The following will combine the Figure 1 to Figure 2 , specifically, clearly and completely describe the technical solutions in the embodiments.

[0037] refer to figure 1 As shown, the combined heavy-duty sliding linear guide in this embodiment includes a guide rail body 1 , fixing screws 4 , a mounting base plate 5 , sliders 6 (5 sets) and a guided object 7 .

[0038] The guide rail body 1 includes an upper end face and two side surfaces, and an anti-turnover inclined surface is also provided on the side surface; the guide rail body 1 and the installation base plate 5 are fixedly connected by fixing screws 4, and the slider 6 slides along the guide rail body 1, thereby The guided object 7 can move linearly along the surface of the guide rail body 1 .

[0039] The guide block includes an upper guide block 2 and a side guide block 3 . The upper guide block 2 and the side guide block 3 are set on the guide rail body 1 at the same time, that is, the three-function guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com