Lockable reversing valve

A reversing valve with lock technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of increasing the difficulty of valve body casting, reducing operating comfort, increasing operating force, etc., to achieve convenient Processing, ensuring the comfort of operation, and the effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

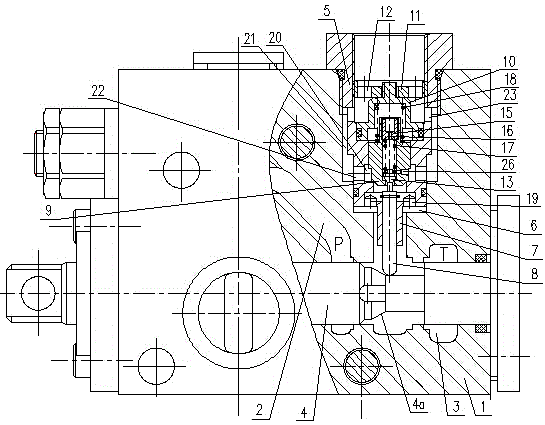

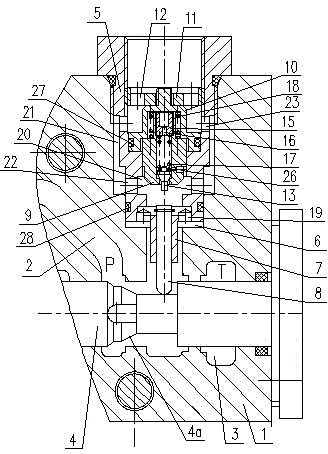

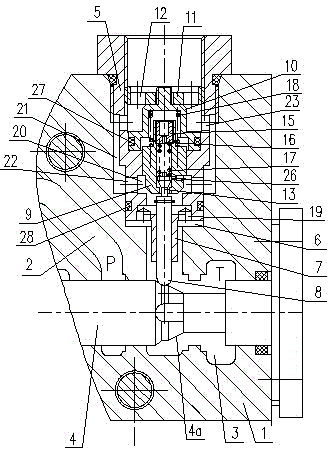

[0018] Such as Figure 1 to Figure 3 As shown, the reversing valve with lock includes a valve body 1, an oil inlet 2 located in the valve body 1, an oil return port 3, two working oil ports and a slide valve 4, and passes through one of the working oil ports 6 The thread is equipped with a valve sleeve 5 with an inner hole, and the end of the valve sleeve 5 close to the slide valve 4 is provided with a guide sleeve 7 which is set in a radial gap with the front end of the working oil port, and a push rod 8 is provided for sliding in the guide sleeve 7 , the slide valve 4 between the push rod 8 and the oil inlet 2 is provided with a gradually rising conical surface 4a; a valve core 9 is provided sliding in the valve sleeve 5 above the push rod 8, and above the valve core 9 A limit seat 10 is provided in the valve sleeve 5, and a limit screw plug 11 in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com