Blue brick firing method

A technology of green bricks and adobes, which is applied in the field of green brick firing, can solve problems such as difficult control of the firing process, discontinuous firing process, and difficult quality control, so as to improve energy utilization, gas utilization, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

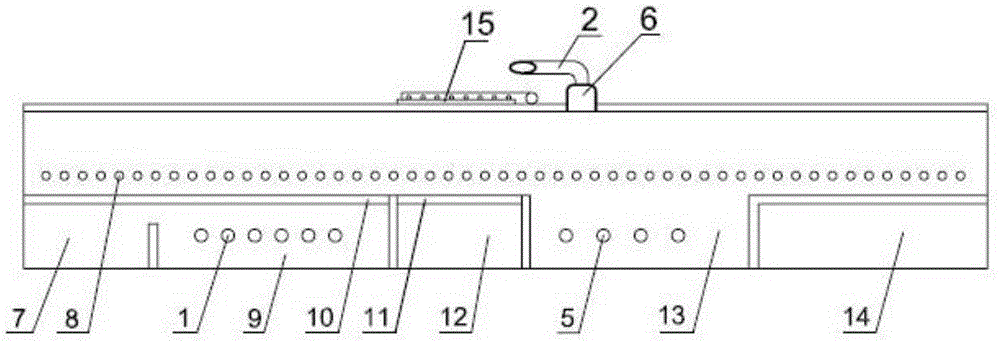

[0021] combined with figure 1 with figure 2 , a green brick firing method, the steps are:

[0022] S1, raw material pulping, by weight 50 parts of red shale, 25 parts of black shale, 25 parts of red sand, 1 part of diluent, put into ball mill, add water until the water content of raw materials is 33-35%, carry out ball milling, and the particle size reaches 250 mesh sieve The remaining 5.5-6.0%, filter out the mud and stir in the slurry tank for 24 hours before use;

[0023] S2, making powder, spraying the mud into the drying tower for drying, after drying, the moisture accounts for 7.8-8.2% by weight, and the mud powder is screened and graded, 20 mesh: 40 mesh: 60 mesh: 80 mesh: 100 mesh, according to the weight ratio 10:40:35:10:5 mixing, the powder is mixed and placed in the silo for more than 24 hours, and set aside;

[0024] S3, compacting, sending the stale mixed powder into the compacting machine to press the adobe for standby;

[0025] S4, preheating, the adobe en...

Embodiment 2

[0032] This embodiment is the following steps:

[0033] S1, raw material pulping, by weight 50 parts of red shale, 25 parts of black shale, 25 parts of red sand, 1 part of diluent, put into ball mill, add water until the water content of raw materials is 33-35%, carry out ball milling, and the particle size reaches 250 mesh sieve The remaining 5.5-6.0%, filter out the mud and stir in the slurry tank for 24 hours before use;

[0034] S2, making powder, spraying the mud into the drying tower for drying, after drying, the moisture accounts for 7.8-8.2% by weight, and the mud powder is screened and graded, 20 mesh: 40 mesh: 60 mesh: 80 mesh: 100 mesh, according to the weight ratio 10:40:35:10:5 mixing, the powder is mixed and placed in the silo for more than 24 hours, and set aside;

[0035] S3, compacting, sending the stale mixed powder into the compacting machine to press the adobe for standby;

[0036] S4, preheating, the adobe enters the preheating section 7 of the kiln, the...

Embodiment 3

[0042] This embodiment is the following steps:

[0043] S1, raw material pulping, by weight 50 parts of red shale, 25 parts of black shale, 25 parts of red sand, 1 part of diluent, put into ball mill, add water until the water content of raw materials is 33-35%, carry out ball milling, and the particle size reaches 250 mesh sieve The remaining 5.5-6.0%, filter out the mud and stir in the slurry tank for 24 hours before use;

[0044] S2, making powder, spraying the mud into the drying tower for drying, after drying, the moisture accounts for 7.8-8.2% by weight, and the mud powder is screened and graded, 20 mesh: 40 mesh: 60 mesh: 80 mesh: 100 mesh, according to the weight ratio 10:40:35:10:5 mixing, the powder is mixed and placed in the silo for more than 24 hours, and set aside;

[0045] S3, compacting, sending the stale mixed powder into the compacting machine to press the adobe for standby;

[0046] S4, preheating, the adobe enters the preheating section 7 of the kiln, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com