Mobile and portable strap cutting machine

A shearing machine and a convenient technology, applied in the field of movable and convenient strapping shearing machines, can solve the problems of low work efficiency, self-weight of strapping, easy rust, etc., so as to solve the problems of low efficiency, ensure stable performance and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

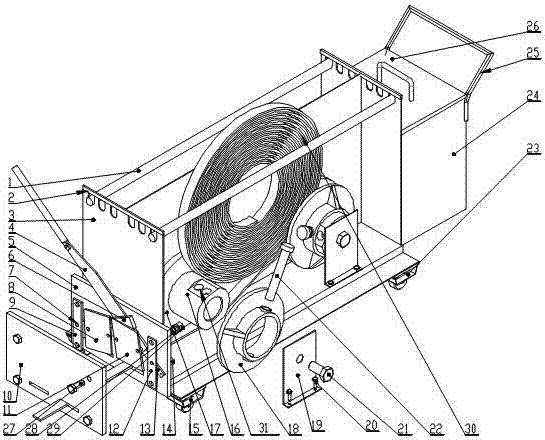

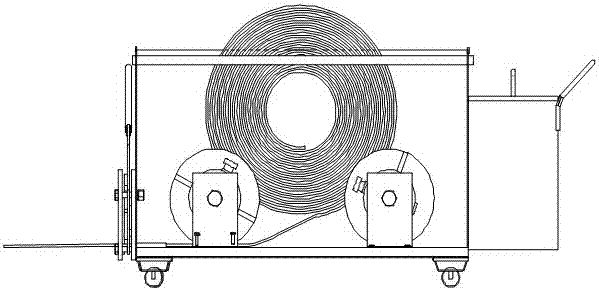

[0020] Such as Figure 1-2 Shown: the mobile and portable strap shearing machine of the present invention includes a main frame, a main frame center plate is installed in the middle of the main frame, and strap fixing adjustment mechanisms are respectively installed on both sides of the main frame center plate A shearing mechanism is installed on one side of the main frame, and storage boxes and handrails are installed on the other side of the main frame.

Embodiment 2

[0022] In the movable and portable strap shearing machine described in Embodiment 1, the shearing frame includes an inner panel welded on the main frame, and a left drive plate and a right drive plate are respectively hinged on the inner panel, and the Both the left transmission plate and the right transmission plate are connected to the operating handle, the left transmission plate is fixedly connected to the left shearing plate, the operating handle is fixedly connected to the right shearing plate, and the inner panel is made The positioning plate and the right positioning plate are connected to the outer panel, and the main frame, the inner panel, and the outer panel are respectively provided with binding outlets, and the binding openings are located between the left shear plate and the outer panel. The right clipboard below.

Embodiment 3

[0024] In the movable and portable strap shearing machine described in Embodiment 1, the strap fixing and adjusting mechanism includes shafts installed on both sides of the center plate of the main frame, and shaft sleeves are installed on the shafts, and the The shaft sleeve is provided with a strap width adjustment hole, and the shaft sleeve is provided with an axial positioning sleeve outside, and the axial positioning sleeve has a pin hole, and the axial positioning sleeve is inserted into the pin hole and The strap width adjustment holes on the shaft sleeve are connected, and the axial positioning sleeve is fixed on the main frame through an axial fixing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com