Automatic mechanical device for shaft and sleeve cooperation

A sleeve matching and mechanical device technology, applied in the field of mechanical parts assembly device, can solve the problems of difficult continuous production, difficult for small enterprises, heavy work, etc., and achieves the effects of tight equipment, high degree of automation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

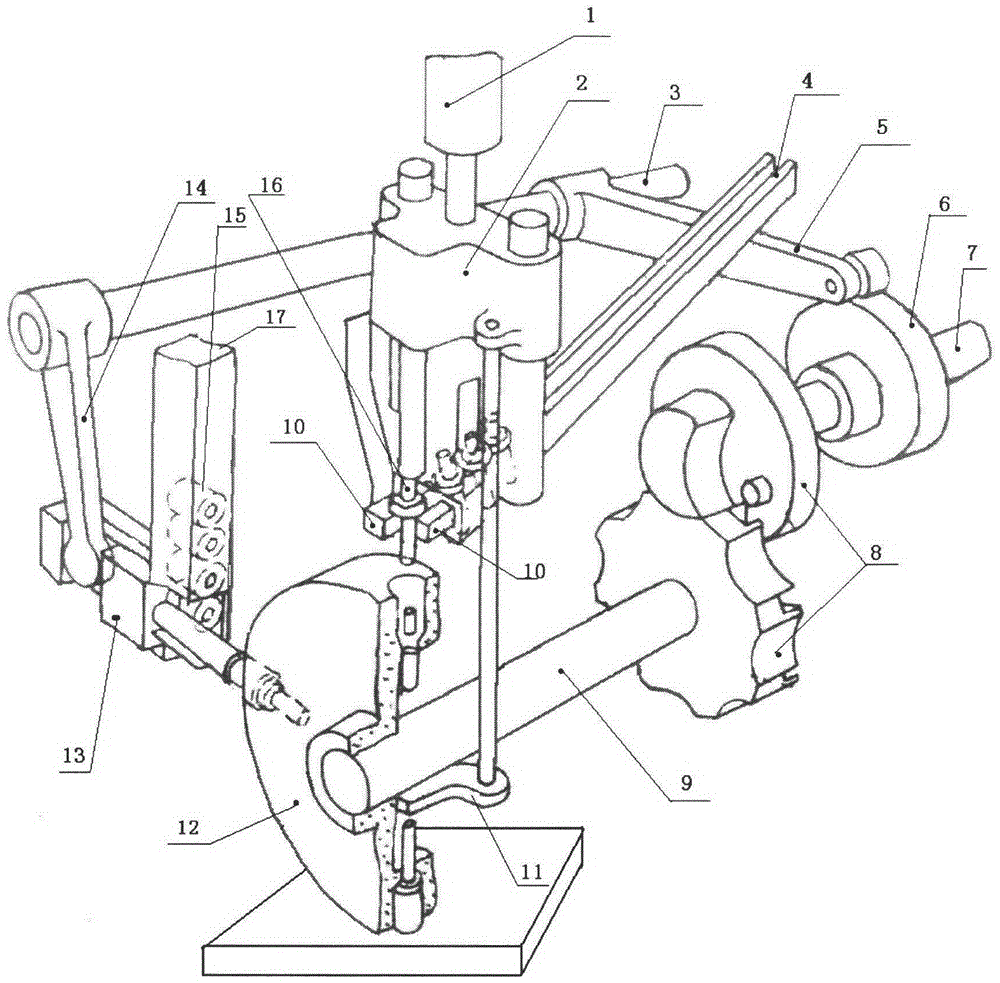

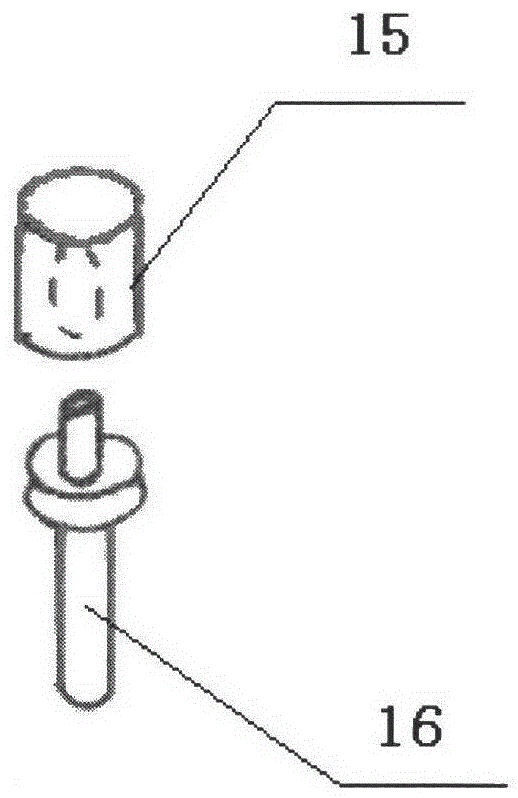

[0025] Such as figure 1 As shown, when a batch of plastic sleeves 15 and the stepped shaft 16 need to be press-fitted with a certain pressure, the plastic sleeves 15 can be placed on the slope slideway ( figure 1 Not shown in), the plastic sleeve 15 will slide into the square container 17 along the ramp slide. Place the stepped shaft 16 in the chute 4 in advance, the chute 4 is placed obliquely, the angle between the chute 4 and the horizontal plane is 25 degrees to 35 degrees, the stepped shaft 16 can continuously slide to the bottom of the chute 4, which can make the production continuous to automate. Now turn on the motor (not shown) to drive the camshaft 7, the camshaft 7 drives the cam 6 and the sheave mechanism 8, the sheave mechanism 8 drives the main shaft 9, the main shaft 9 drives the indexing dial 12 to rotate intermittently, and the cam 6 promotes the continuous Bar 5, connecting rod 5 drive rotating shaft 3, and rotating shaft 3 drives pusher 14, and pusher 14 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com