A rocker punching machine for water-saving irrigation sprinkler belt

A rocker-type, punching machine technology, applied in metal processing, etc., can solve the problems of uncontrollable air pressure, fast and slow punching speed, easy aging of solenoid valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

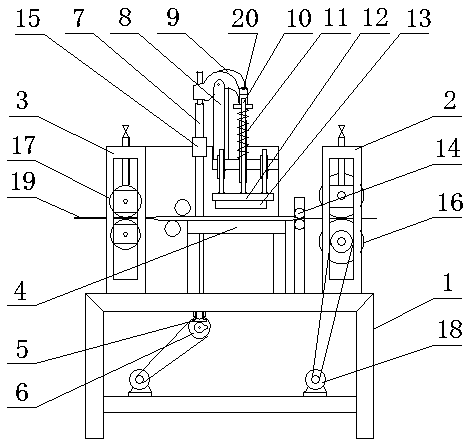

[0015] The rocker type puncher of this water-saving irrigation sprinkler belt consists of a frame 1, a traction bracket 2, a delivery bracket 3, a punching platform 4, a rocker ejector rod 7, a rocker bracket 8, a rocker arm 9, and a slide bar 10. , spring 11, slide plate 12, needle plate 13, backing plate locator 14, servo motor 18, the left and right sides above the frame 1 are respectively equipped with conveying support 3 and traction support 2, conveying roller 17 is housed on the conveying support 3, A traction roller 16 is installed on the traction bracket 2; a punching platform 4 is installed on the middle part above the frame 1, and a backing plate positioner 14 is installed on one side of the punching platform 4. The drilling platform 4 is equipped with a rocker arm push rod 7 through a conduit 15, and the annular gap between the rocker arm push rod 7 and the conduit 15 is 3 to 5 millimeters. One side of the rocker arm push rod 7 is equipped with a rocker arm bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com