Amine-functionalized graphene/tio with selective photocatalytic degradation 2 Preparation method of composite material

A composite material and photocatalytic technology, which is applied in the field of preparation of amine-functionalized graphene/TiO2 composite materials, achieves the effects of low equipment requirements, simple operation, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

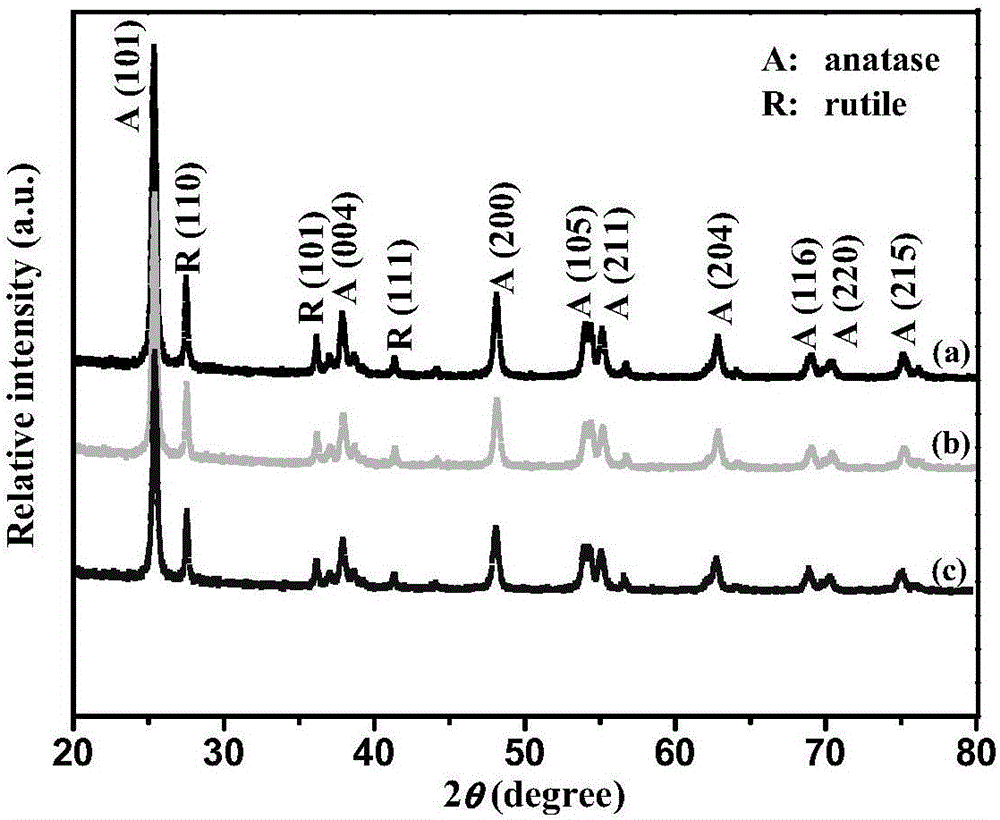

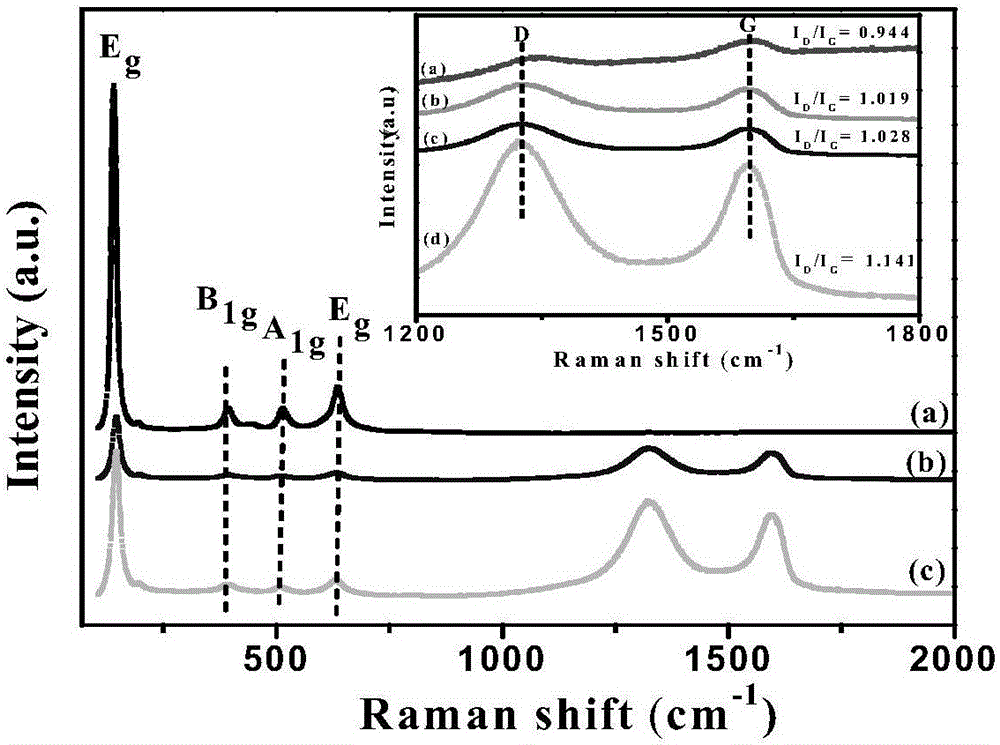

Embodiment 1

[0027] PhNH 2 / rGO-TiO 2 The preparation process of the photocatalyst is as follows: (1) 0.2g commercial P25TiO 2 Add the powder into 10mL graphene oxide (0.2mg / mL) solution, stir evenly to form a stable suspension solution, in which graphene oxide and TiO 2 The mass ratio of is 1wt%; (2) the TiO of step (1) configuration 2 Transfer the blackene oxide suspension to a hydrothermal kettle, and conduct a hydrothermal reaction at a constant temperature of 160°C for 8 hours to obtain a reduced graphene-modified titanium dioxide composite material; (3) uniformly disperse the product obtained in step (2) into the aniline The impregnation treatment is carried out in the ethanol solution, wherein the mass ratio of aniline to graphene oxide is 30:1; (4) under stirring, the mixed solution obtained in step (3) is placed at a constant temperature of 35 ° C for 5 hours, and the obtained product After being washed three times with alcohol and water respectively, and then dried at a consta...

Embodiment 2

[0036] In order to examine the effect of hydrothermal reaction temperature on PhNH 2 / rGO-TiO 2 Influence of photocatalyst photocatalytic selectivity, in addition to hydrothermal reaction temperature, other reaction conditions such as hydrothermal reaction time (8h), mass ratio of aniline to graphene oxide (30:1), immersion temperature (35°C), immersion time (5h), drying temperature (60 DEG C) etc. are all identical with embodiment 1. The results show that when the hydrothermal reaction temperature is 100 °C, TiO 2 It is not well combined with rGO, and the degree of reduction of GO is low, the formed PhNH 2 / rGO-TiO 2 Photocatalysts cannot selectively degrade MO; when the hydrothermal reaction temperature is 140-180 °C, the degree of reduction of GO is high, and uniform and stable TiO can be formed 2 -rGO composite phase, and then formed PhNH 2 / rGO-TiO 2 Photocatalysts have the ability to efficiently and selectively degrade MO; when the hydrothermal reaction temperature...

Embodiment 3

[0038] In order to examine the effect of hydrothermal reaction time on PhNH 2 / rGO-TiO 2 Influence of photocatalyst photocatalytic selectivity, in addition to hydrothermal reaction time, other reaction conditions such as hydrothermal reaction temperature (160°C), mass ratio of aniline to graphene oxide (30:1), impregnation temperature (35°C), impregnation Time (5h), drying temperature (60° C.) etc. are all the same as in Example 1. The results show that when the hydrothermal reaction time is 1 h, the reduction degree of GO is low due to the short hydrothermal time, and the synthesized PhNH 2 / rGO-TiO 2 The photocatalyst does not have the ability to selectively degrade MO; when the hydrothermal reaction time is 6-10h, GO can be effectively reduced to rGO, and the formed PhNH 2 / rGO-TiO 2 The photocatalyst has obvious photocatalytic selective degradation performance on MO. When the hydrothermal time is extended to 15h, PhNH 2 / rGO-TiO 2 The photocatalytic selective perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com