Thermal-insulating apparatus of reaction barrel

A technology of heat preservation device and reaction barrel, which is used in heat storage heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of incomplete reaction of raw materials, uneven heating of the reflected barrel, etc., and achieve the effect of ensuring a constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

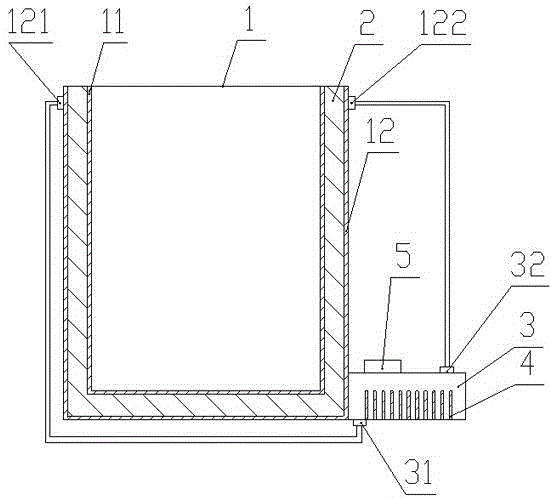

[0008] Such as figure 1 As shown, the present invention includes a reaction barrel body 1, the reaction barrel body 1 includes an inner barrel 11 and an outer barrel 12, the inner barrel 11 is located in the outer barrel 12, and an airtight cavity is arranged between the inner barrel 11 and the outer barrel 12 2. The cavity 2 is filled with a heat-conducting liquid, and the reaction barrel body 1 is provided with a heating container 3 for storing the heat-conducting liquid. The heating container 3 is provided with an electric heating rod 4 for treating The heat-conducting liquid placed in the heating container 3 is heated, and the sealed cavity 2 communicates with the heating container 3 . The outer barrel 12 is provided with a liquid outlet 121 and a liquid inlet 122, the liquid outlet 121 is connected to the liquid inlet 31 of the heating container 3, and the liquid inlet 122 is connected to the liquid outlet 32 of the heating container The heating container 3 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com