Full automatic cashew nut hull breaking machine

A shell breaking machine, fully automatic technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of poor safety performance, low productivity, high operating costs, improve production efficiency, reduce labor intensity, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

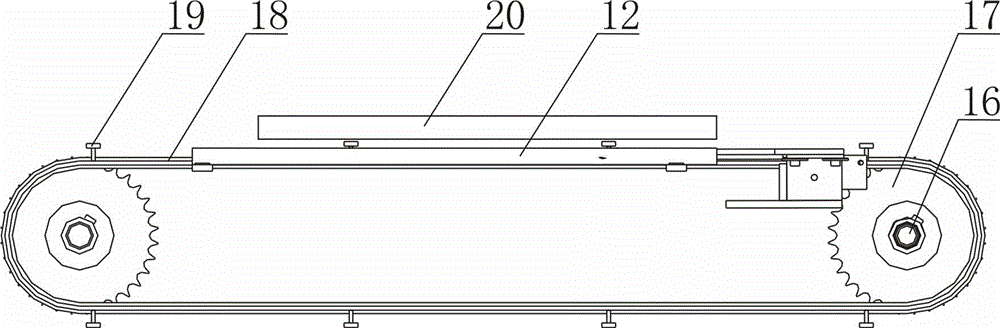

[0025] Such as figure 1 As shown, the fully automatic cashew cracker is mainly composed of a frame 1, a motor 2, a feeding mechanism 3, a conveying mechanism 4 and a cutting mechanism 5, and the motor 2 is the power of the feeding mechanism 3, the conveying mechanism 4 and the cutting mechanism 5 source. The feeding mechanism 3 is arranged on the frame 1 and is located at one end of the guide rail 15 , and the cutting mechanism 5 is arranged on the frame 1 and is located at the other end of the guide rail 15 .

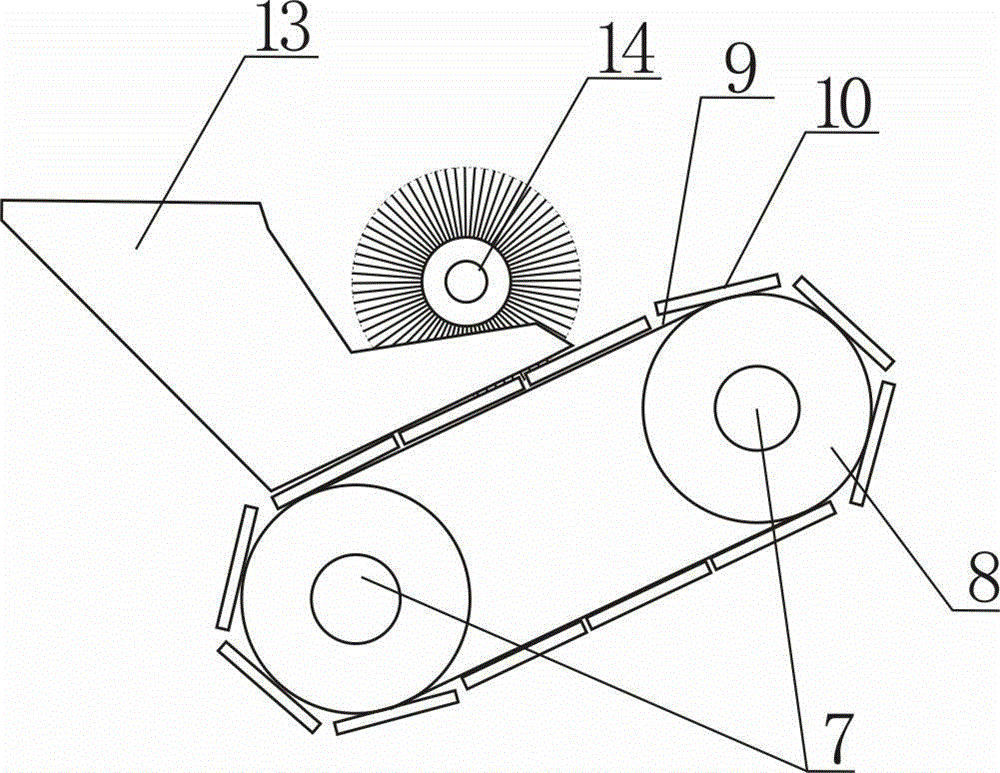

[0026] Such as figure 2 As shown, the feeding mechanism 3 is mainly composed of a feeding hopper 13, a brush roller 14, a fruit plate assembly and a protective funnel 6, wherein the fruit plate assembly consists of two drive shafts 7, a sprocket wheel 8 and two chains 9, 12 fruit plates 10 components, two transmission shafts 7 are located on the frame 1, two chains 9 are located on the two transmission shafts 7 through the sprocket 8, the two chains 9 form a 30 ° in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com