Rubber seed shelling equipment

A rubber seed and equipment technology, applied in the field of rubber seed shelling equipment, can solve problems such as uneven shape, low shelling rate, and large wear, and achieve the effects of improving mechanization efficiency, clean production environment, and scientific equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

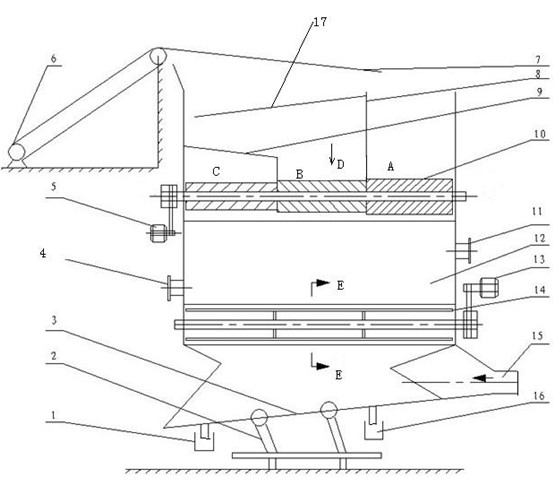

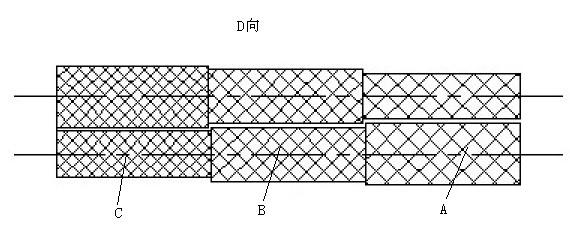

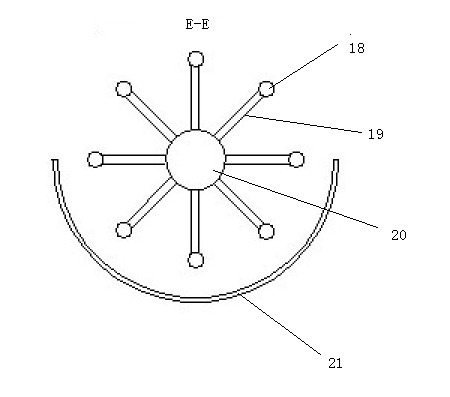

[0019] As shown in the figure, the rubber seed shelling equipment of the present invention consists of a belt bucket elevator 6, primary and secondary screening screens 7, 9, tower wheel shelling gear rollers 10, washboard device 14, primary and secondary air Selector 12, 3, crank rack 2 and power unit (motor 5, 13) constitute; Below the sieve is the tower wheel shelling toothed roller, below the tower wheel shelling toothed roller is the primary winnowing machine 12, below the primary winnowing machine is the washboard device, and below the washboard device is the secondary winnowing machine 3, the crank frame and the two Secondary winnowing machine is connected, and tower wheel shelling gear roller and washboard device are connected motor 5,13 respectively. Wherein: a material guide plate 17 is provided between the primary sorting screen and the secondary sorting screen, and the material guiding plate is connected with the vertical baffle plate 8 . The shelling toothed roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com