Mixed silage containing sweet sorghum and alfalfa, and preparation method of mixed silage

A technology for mixing silage and sweet sorghum, which is applied in the field of mixed silage of sweet sorghum and alfalfa and its preparation, can solve problems such as unretrieved patents, and achieves improvement of animal appetite and feed intake, low pH value, and improved digestion and utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

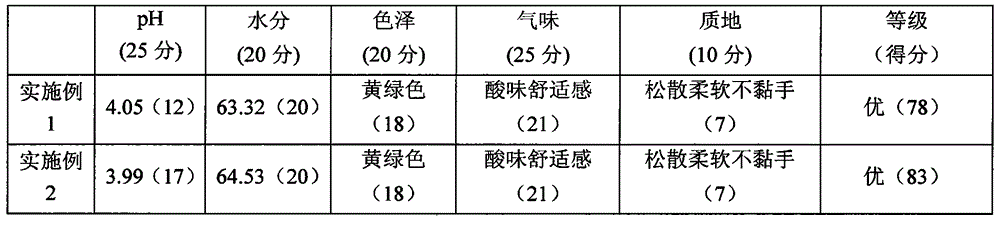

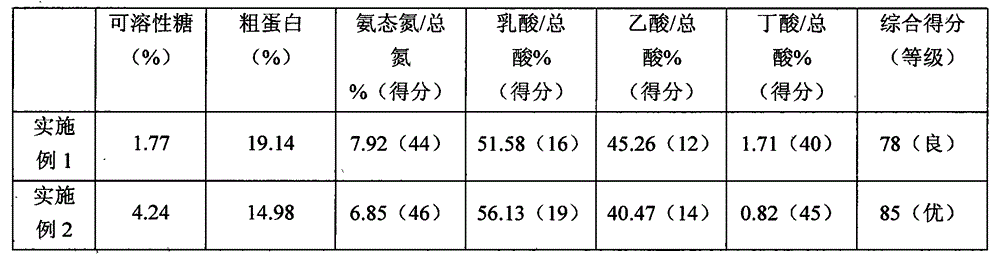

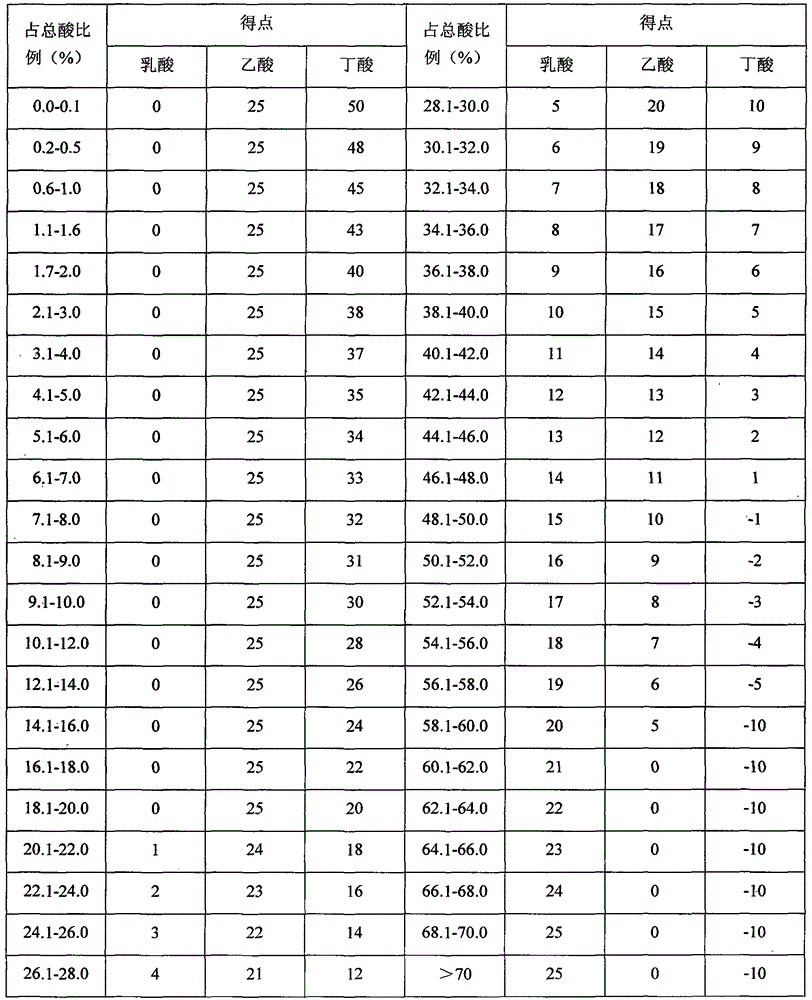

Embodiment 1

[0024] The technical scheme that present embodiment takes is: sweet sorghum and alfalfa mixed silage are made by following steps:

[0025] (1) Harvesting of raw materials: sweet sorghum is harvested at the stage of milk maturity, and alfalfa is harvested at the early flowering stage (5% of alfalfa blooms);

[0026] (2) Chopping: Cut sweet sorghum and alfalfa into 2-4cm long sections respectively;

[0027] (3) Mixing: 20% by weight sweet sorghum and 80% alfalfa are evenly mixed to make filling material.

[0028] (4) Filling and compacting: Fill the above-mentioned fillers in layers in the silo, the thickness of each layer is 50-60cm, and compact them layer by layer, so that the density of the filler after compaction reaches 650-750g / L. The final compacted filling material is 30cm higher than the silage pit mouth.

[0029] (5) Sealing: Cover the silage pit completely with a thick plastic cloth, and the plastic cloth for sealing the mouth of the silage pit is 50 cm more than th...

Embodiment 2

[0032] The technical scheme that present embodiment takes is: sweet sorghum and alfalfa mixed silage are made by following steps:

[0033] (1) Harvesting of raw materials: sweet sorghum is harvested at the stage of milk maturity, and alfalfa is harvested at the early flowering stage (10% of alfalfa is blooming);

[0034] (2) Chopping: Cut sweet sorghum and alfalfa into 2-4cm long sections respectively;

[0035] (3) Mixing: mix 40% sweet sorghum and 60% alfalfa evenly by weight to make filling.

[0036] (4) Filling and compacting: Fill the above-mentioned fillers in layers in the silo, the thickness of each layer is 50-60cm, and compact them layer by layer, so that the density of the filler after compaction reaches 650-750g / L. The final compacted filling material is 50cm higher than the silage pit mouth.

[0037] (5) Sealing: Cover the silage pit completely with a thick plastic cloth, and the plastic cloth for sealing the mouth of the silage pit is 50 cm more than the edge of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com