Method and device for switching a contactor

A technology of contactor and selection scheme, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of uneven corrosion level, contactor service life limit, contact material thickness reduction, etc., and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

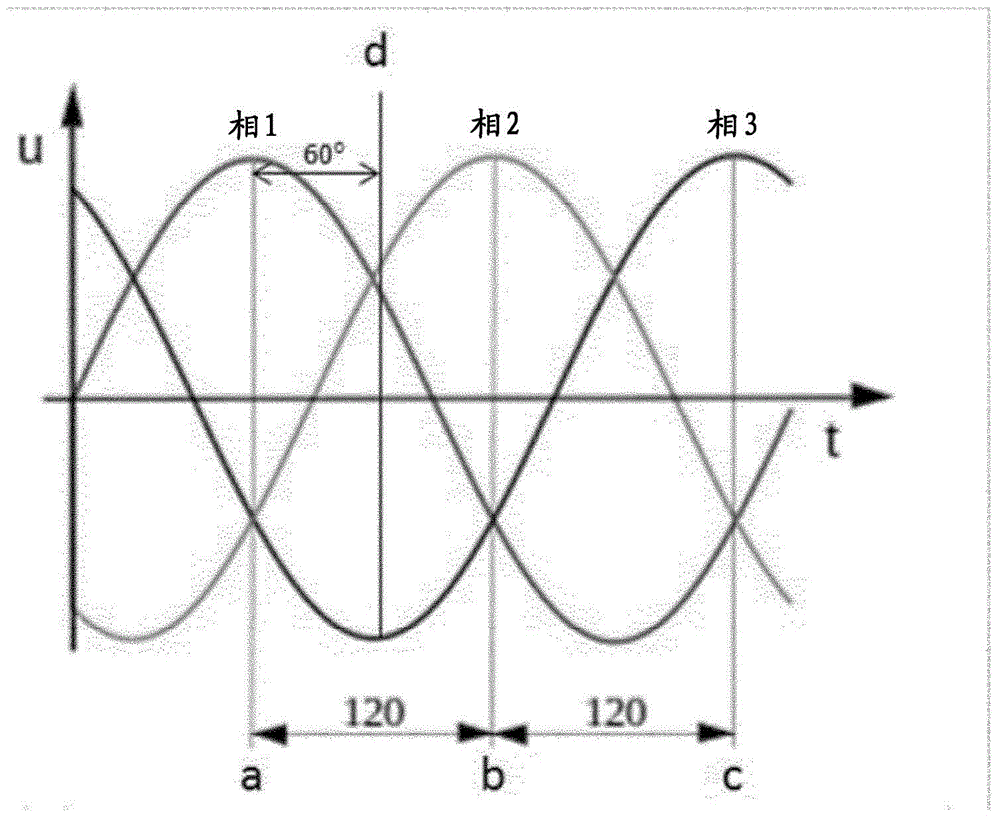

[0028] Figure 4a A low voltage contactor 1 according to an embodiment of the invention is shown. The low-voltage contactor 1 is used to connect the electric load 2 to a three-phase L 1 , L 2 , L 3 or disconnected from the main electrical network of the electrical load 2 in this example the engine.

[0029] The contactor 1 consists of a three-phase L connected to the mains network 1 , L 2 , L 3 Three main contacts 12 in each phase, an actuating unit comprising a coil 10, a fixed magnetic core 16 and a movable iron core 14, electronics for controlling the voltage / power supplied to the coil 10 control circuit 20. Each main contact includes a fixed contact and a movable contact connected to the movable iron core 14 . The coil 10, the fixed magnetic core 16 and the movable iron core 14 are arranged for actuating the main contacts 12, and thus for connecting and disconnecting operations.

[0030] In this example, the control voltage for the electronic control circuit consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com