Double-shielded fire-resistant cable

A fire-resistant cable and double-shielding technology, applied in the field of cables, can solve the problems of weak waterproof and fire-resistant ability, poor anti-shielding ability, etc., and achieve high anti-static interference, strong waterproof and fire-resistant ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

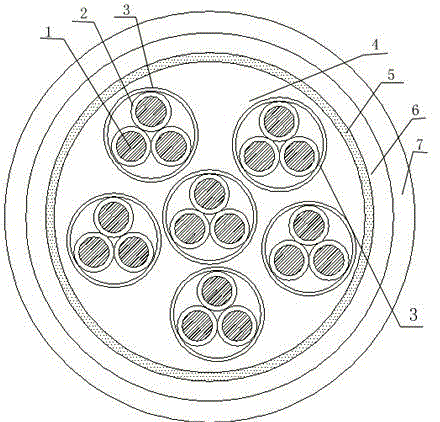

[0016] A double-shielded fire-resistant cable, characterized in that it includes at least three conductors 1, and the conductors are all wrapped with an insulating layer 2, and all the conductors 1 wrapped with the insulating layer 2 are wrapped with an inner shielding layer 3, and the inner shielding layer 3 and the insulating layer 2 The gaps between are filled with fillers 4, the inner shielding layer 3 wraps the outer shielding layer 5, the outer shielding layer 5 wraps the flame-retardant layer 6, the flame-retardant layer 6 wraps the sheath layer 7, the inner shielding layer and the outer shielding layer Each layer includes copper foil with aluminum foil on both sides.

[0017] The filling material 7 is a fire-resistant water-blocking tape, which includes a mica layer, and the two sides of the mica layer are respectively bonded with a reinforcing layer made of glass fiber mesh, and a film composed of water-blocking powder is bonded on the reinforcing layer to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com