Method for rapidly detecting content of polar components in frying oil

A polar component and detection method technology, applied in the oil field, can solve the problems of large amount of organic solvent, long analysis time, complicated operation, etc., and achieve the effect of improving the accuracy of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First-class soybean oil: purchased in supermarkets;

[0033] French fries: purchased from a supermarket, 40×7.2×7.2mm;

[0034] Frequency-domain dielectric spectrum tester: E5062B network analyzer, Agilent, USA;

[0035] Digital thermometer: LR4210, Yokogana, Japan.

[0036] Use 10 liters of commercial grade soybean oil to fry French fries continuously, heat to 168.3°C and maintain 168.3±5°C.

[0037] French fries of a set size and equal quality were put into a pan for frying, frying for 12 hours a day for 10 days, and samples were taken every 6 hours. The collected samples were transferred to stoppered vials and stored at 4°C.

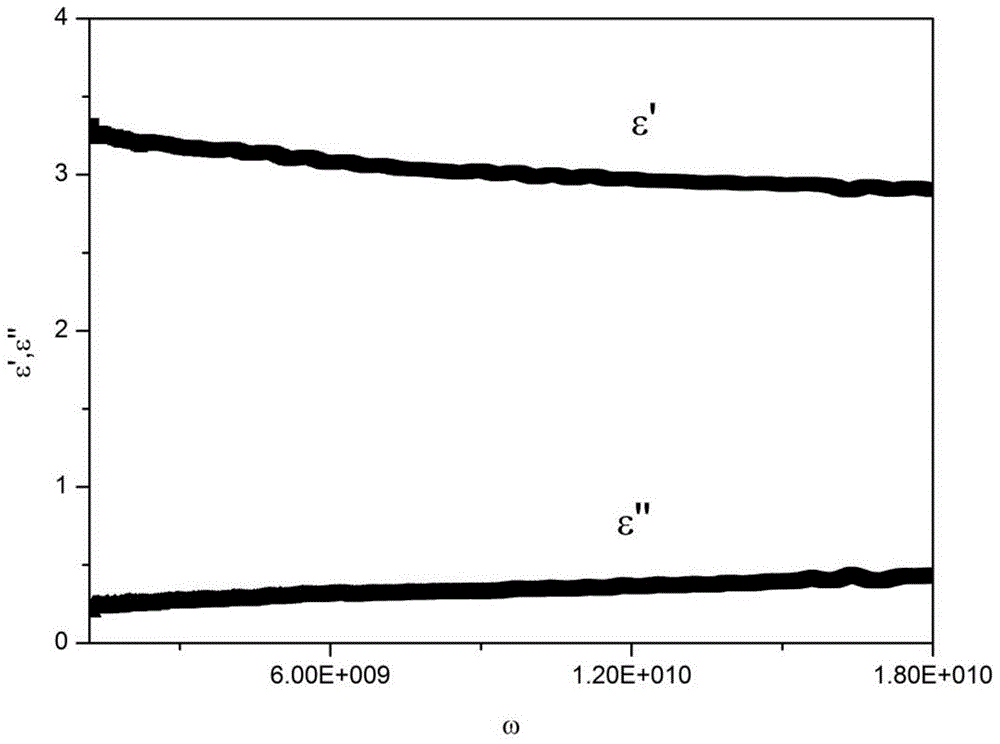

[0038] Add the collected frying oil sample to the detection pool, insert the detection probe, and when the detection probe of the frequency domain dielectric spectrum tester is put into the detection pool of the frying oil sample to be tested, ensure that the detection probe is not in contact with the wall of the detection pool. Contact eac...

Embodiment 2

[0049] Palm oil: purchased in supermarkets;

[0050] Chicken nuggets: purchased from a supermarket, 40×30×10mm;

[0051] Frequency-domain dielectric spectrum tester: E5062B network analyzer, Agilent, USA;

[0052] Digital thermometer: LR4210, Yokogana, Japan.

[0053] Use about 10 liters of commercially available palm oil to fry chicken nuggets continuously, heat to 182.5°C and maintain 182.5±5°C.

[0054] Put chicken nuggets of set size and equal quality into the pan for frying, frying for 12 hours a day for 10 days, sampling every 6 hours. The collected samples were transferred to stoppered vials and stored at 4°C.

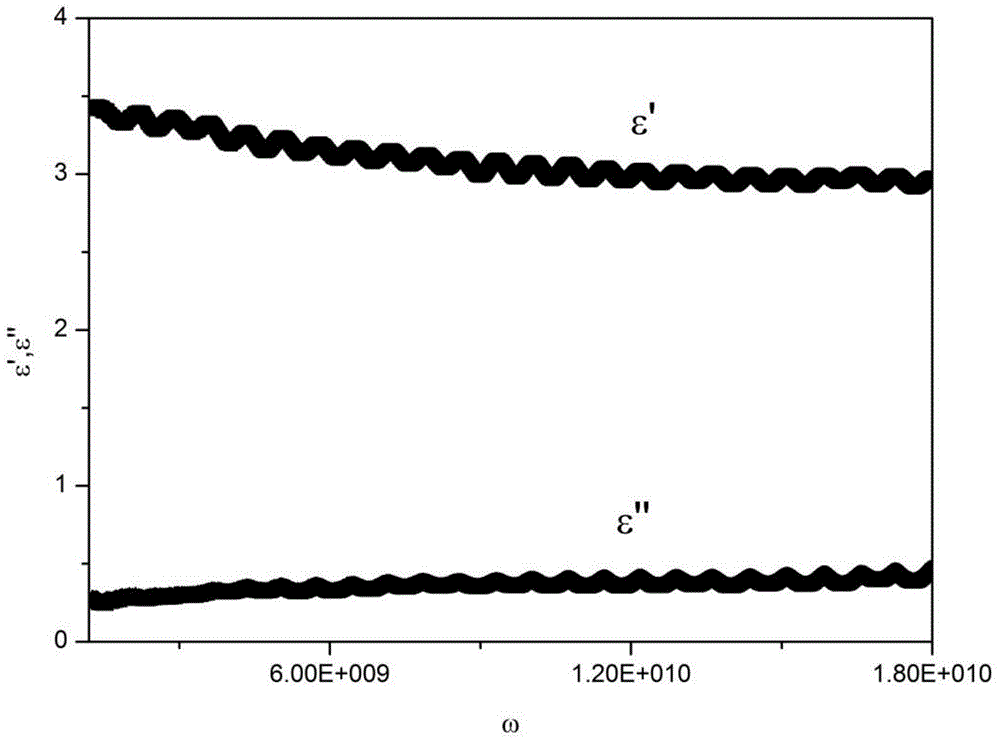

[0055] Add the collected frying oil sample to the detection pool, insert the detection probe, and when the detection probe of the frequency domain dielectric spectrum tester is put into the detection pool of the frying oil sample to be tested, ensure that the detection probe is not in contact with the wall of the detection pool. Contact each other, make the fr...

Embodiment 3

[0066] Blending oil: purchased in supermarkets;

[0067] Fish steak: purchased from a supermarket, 70×60×13mm;

[0068] Frequency-domain dielectric spectrum tester: E5062B network analyzer, Agilent, USA;

[0069] Digital thermometer: LR4210, Yokogana, Japan.

[0070] Use about 10 liters of commercially available blended oil to fry fish fillets continuously, heat to 182.5°C and maintain 182.5±5°C.

[0071] Fish fillets with a set size and equal quality were put into a pan for frying, and they were fried for 12 hours a day for 10 days, and samples were taken every 6 hours. The collected samples were transferred to stoppered vials and stored at 4°C.

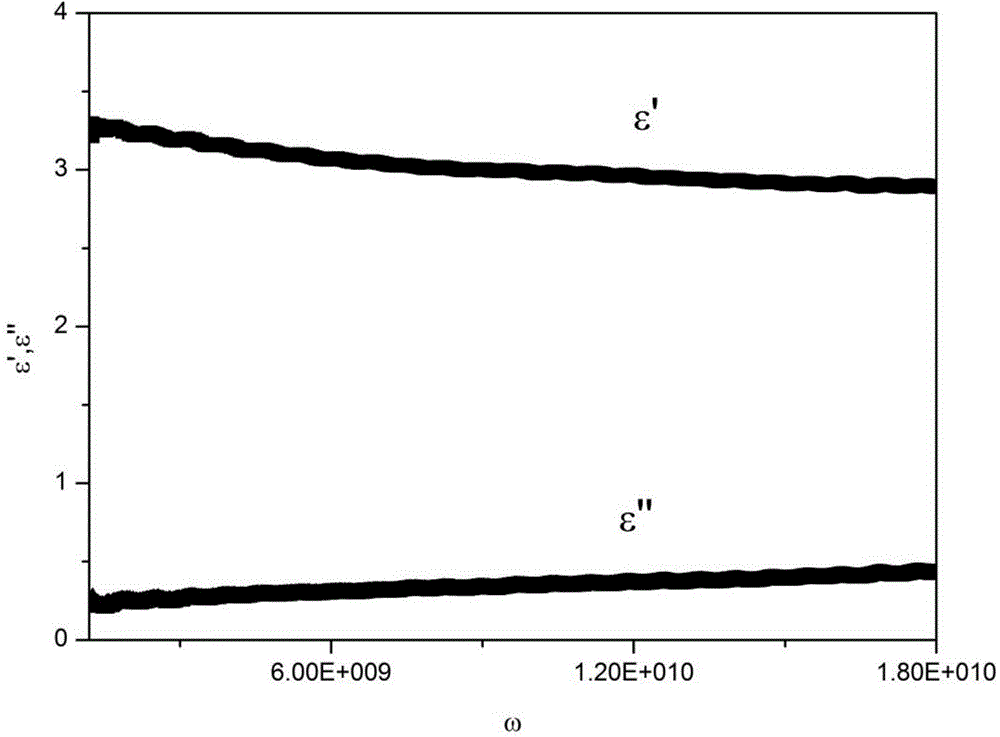

[0072] Add the collected frying oil sample to the detection pool, insert the detection probe, and when the detection probe of the frequency domain dielectric spectrum tester is put into the detection pool of the frying oil sample to be tested, ensure that the detection probe is not in contact with the wall of the detection pool. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com