A Rotor Rubbing Fault Detection Method and System Based on Nonlinear Compression Transform

A non-linear compression and fault detection technology, applied to vibration measurement in solids, testing of machine/structural components, measuring vibration and other directions, it can solve problems such as difficulty in locating rotor system rubbing faults, and achieve fast and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

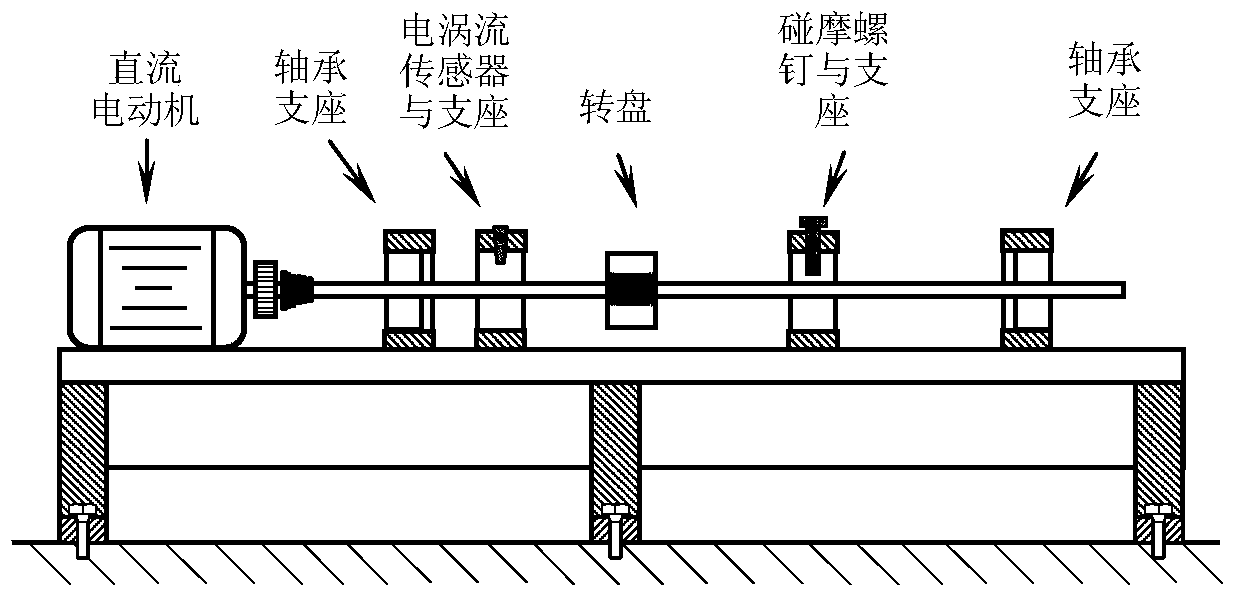

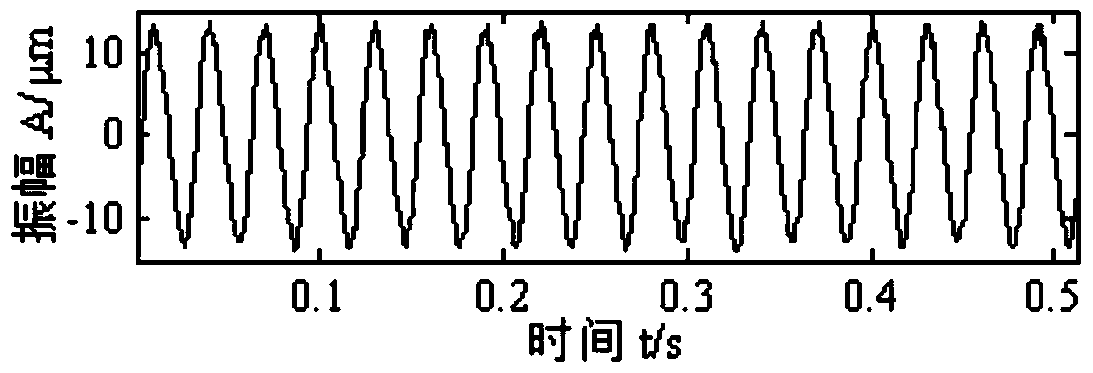

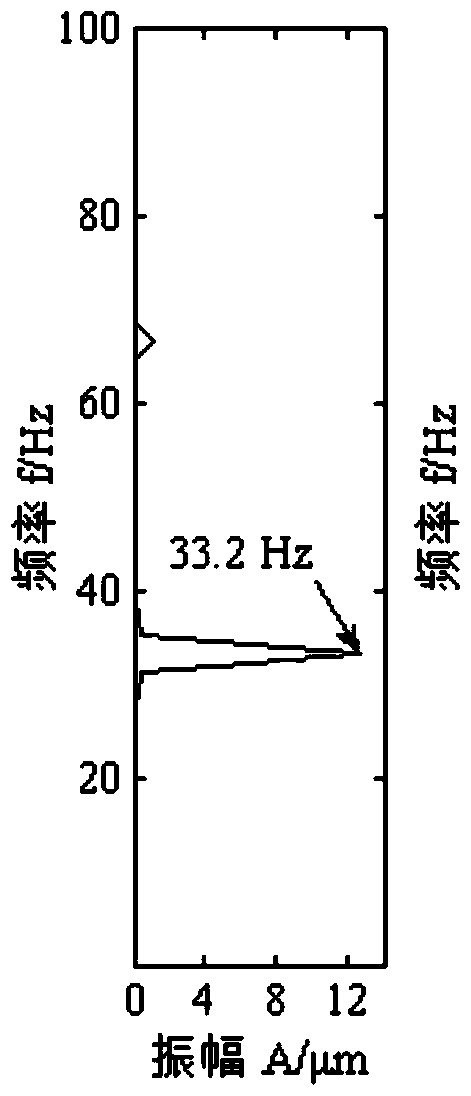

[0035] In a basic embodiment, a rotor rubbing fault detection method based on nonlinear compressive transformation is provided. The method obtains the time-frequency representation of the vibration signal by performing nonlinear compressive transformation on the vibration signal of the rotor system, and combines the The time-frequency representation calculates the instantaneous frequency of the vibration signal, and then further calculates the frequency spectrum of the oscillation part of the instantaneous frequency; assuming f r is the rotation frequency of the rotor system, if the maximum spectral peak of the spectrum is located at [0.99f r , 1.01f r ] range and the amplitude exceeds 2% of the rotational frequency, it can be determined that the rotor system has a rubbing fault; otherwise, it is determined that the rotor system does not have a rubbing fault; the nonlinear compression transformation includes the following steps:

[0036] S100: Calculate the short-time Fourier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com