Revolving shaft calibration method under binocular vision

A technology of binocular vision and calibration method, applied in the field of computer vision, can solve the problems of low calibration efficiency and complex calibration device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

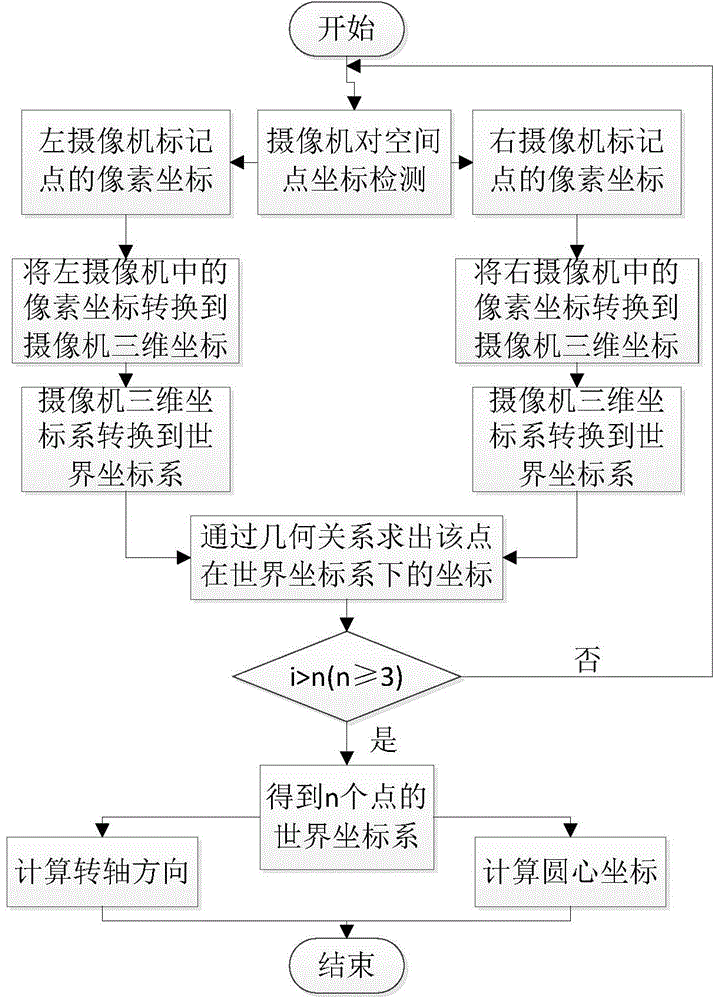

[0074] The present invention provides a method for calibrating the rotating shaft under binocular vision, such as figure 1 As shown, the specific steps are as follows:

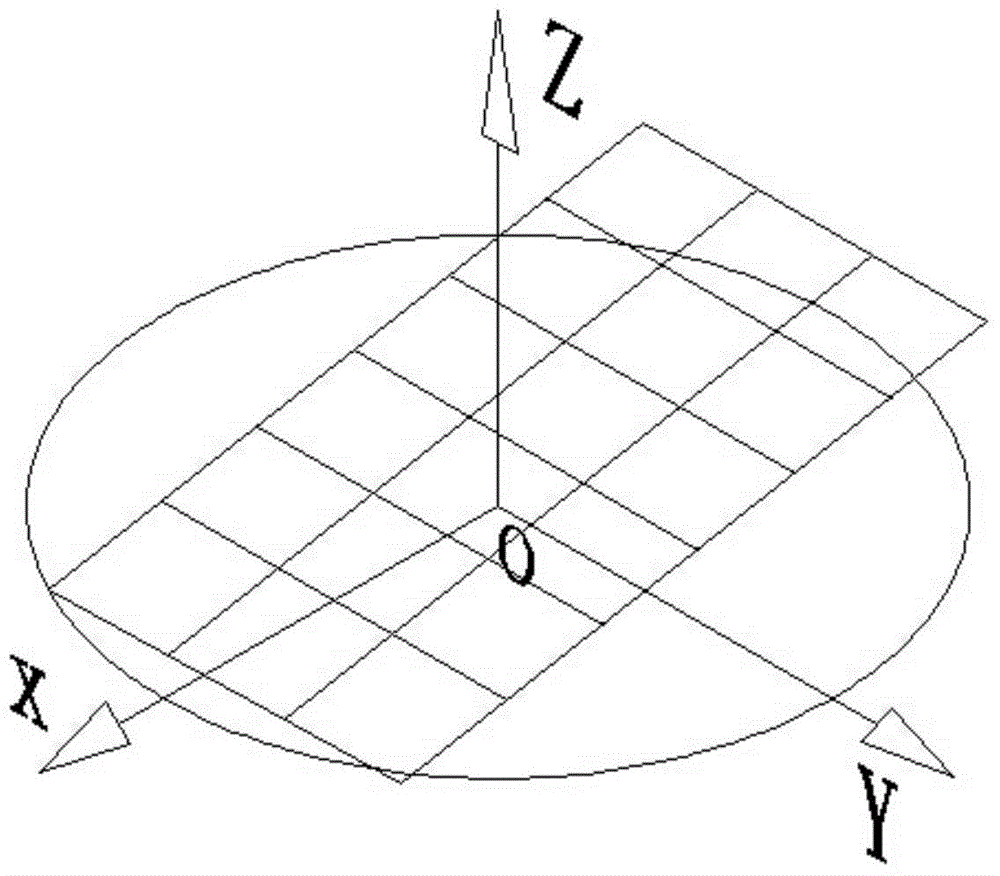

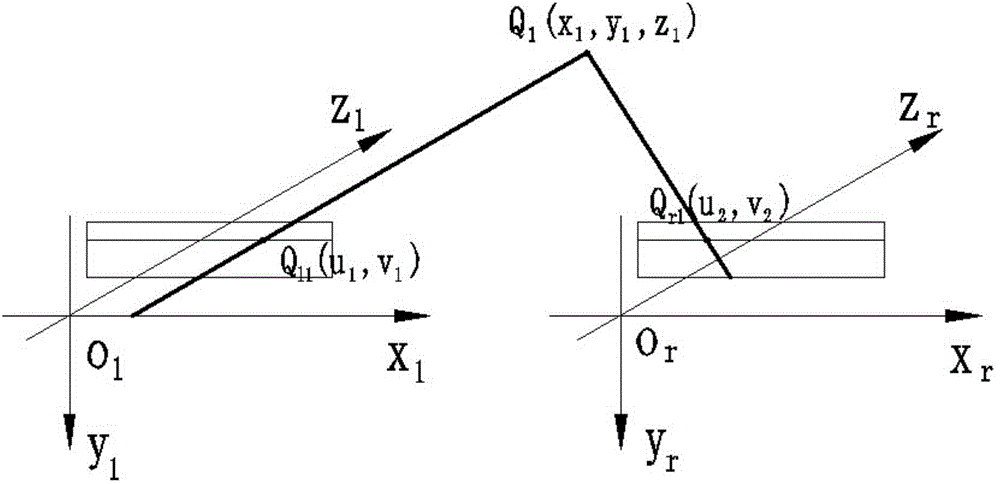

[0075] Step 1, place the rotating platform in the field of view of the two cameras, and place the calibration plate on the rotating platform; record the two cameras as the left camera and the right camera respectively; where the positioning of the calibration plate depends on The relative position of the two cameras and the rotary table, when placing the calibration board, it is necessary to ensure that the calibration board as a whole is within the common field of view of the two cameras before and after the rotation of the rotary table, and the corner points of the checkerboard can be detected. , when the camera lens is higher than the plane of the turntable, the calibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com