A railway ballastless track walking type drop shaft test bench

A technology of ballastless track and test bench, which is applied in the direction of track, track maintenance, road, etc., can solve the problems of inability to simulate the transverse stiffness of double-rail track, inability to test long unit track slabs, and inability to transfer test points for falling shafts, so as to avoid Accumulation of lateral offset, elimination of lateral offset, simple and convenient test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

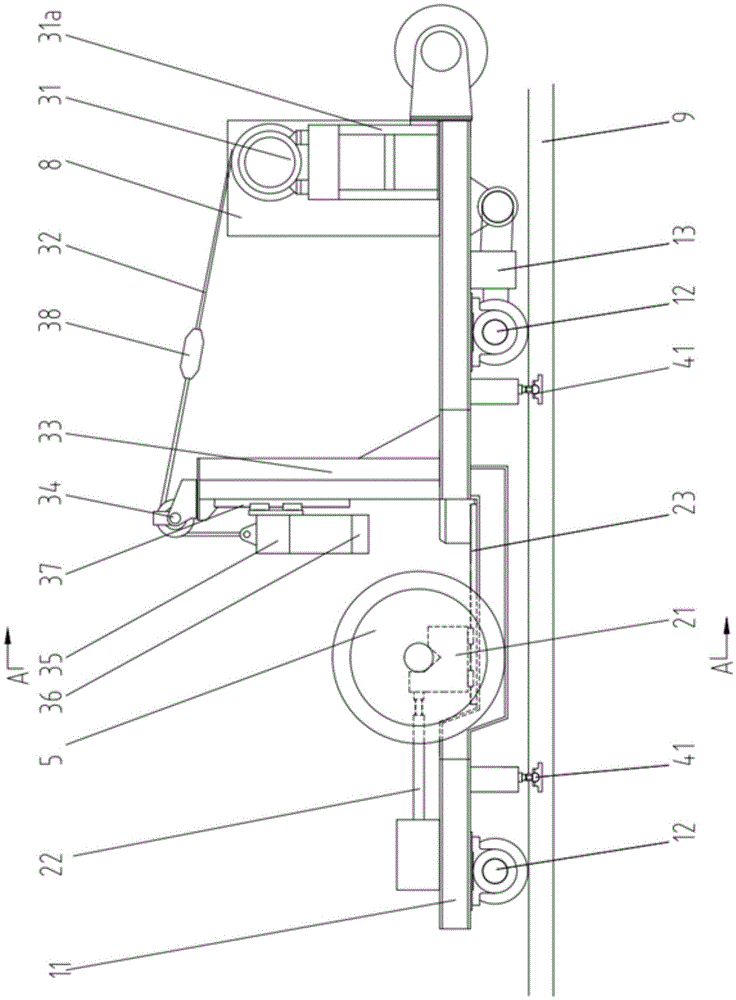

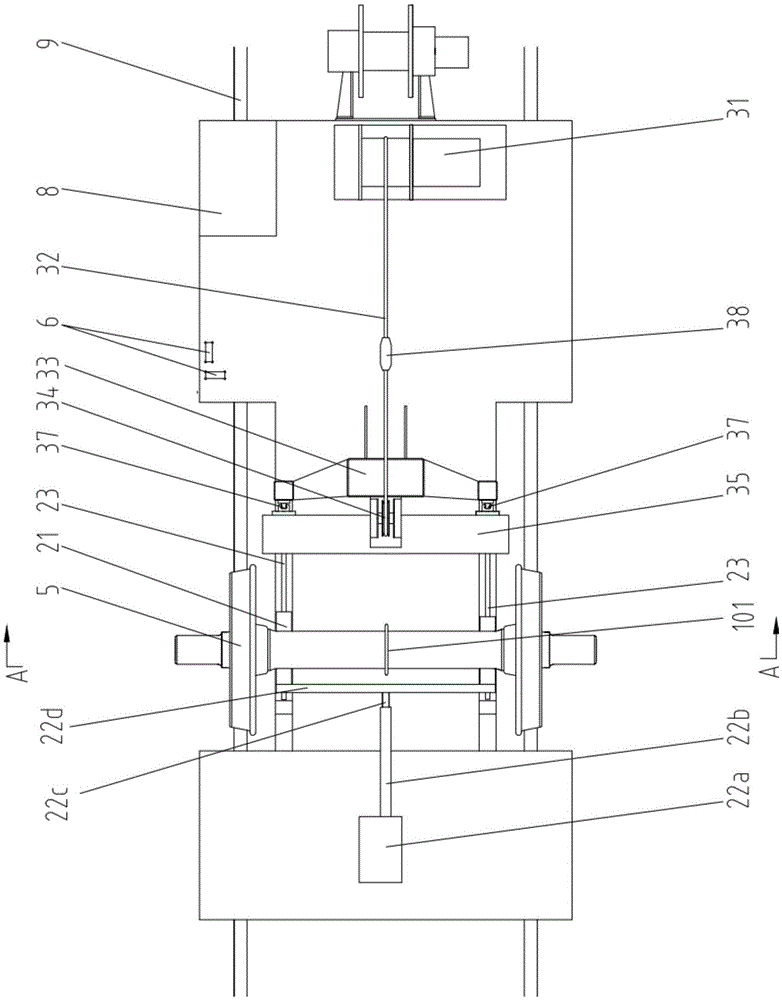

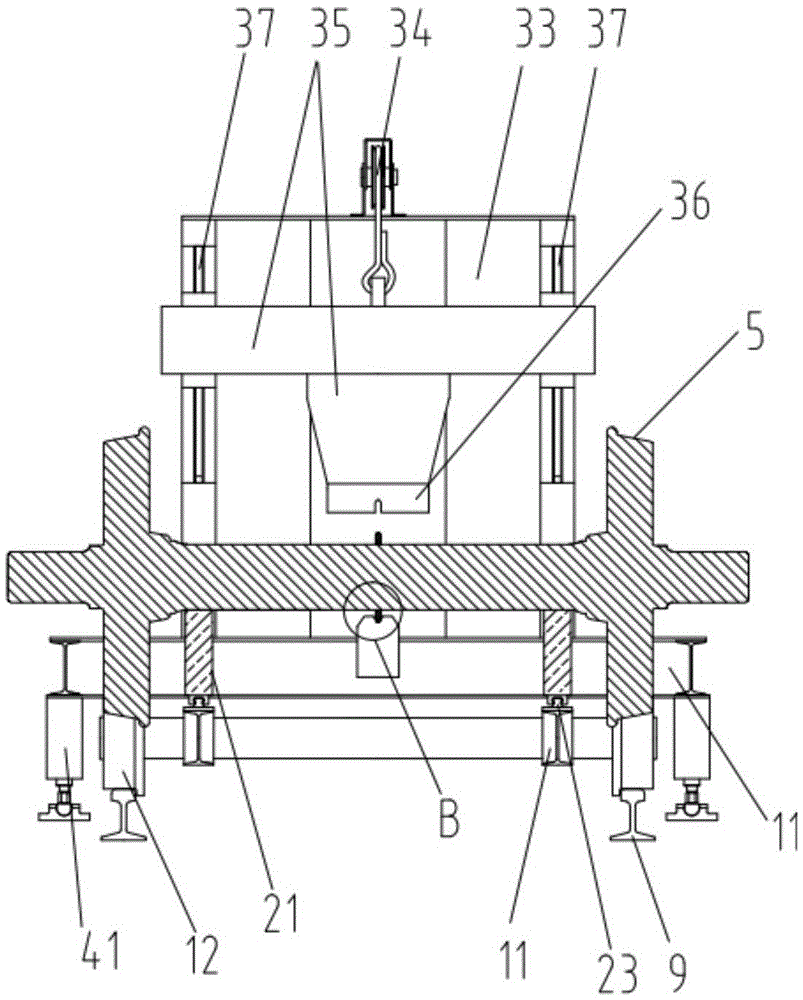

[0042] Figure 1~4 As shown, a specific embodiment of the present invention is: a railway ballastless track walking type drop axle test bench, including a load-carrying running device, a wheel set supporting and moving device, a wheel set lifting device, a vehicle wheel set 5, and a control device 8. Its structural characteristics are:

[0043] The composition of the load-carrying running device is as follows: two pairs of running wheels 12 adapted to the rails 9 of the track are installed on the bottom of the chassis 11, wherein the shafts of a pair of running wheels 12 are connected to the power mechanism 13 on the chassis 11 ;

[0044] The composition of wheelset supporting and moving device 2 is: the upper surface of underframe 11 middle part is respectively connected with a wheelset support block 21 by two longitudinal slide rails 23, and wheelsets support block 21 is also installed with underframe 11 front parts. The electric push rod mechanism 22 is connected; the axl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com