Weft yarn detector for air-jet looms

A technology of air-jet looms and detectors, which is applied to looms, auxiliary weaving equipment, textiles, etc., and can solve problems such as difficult inspection of weft yarns by stroboscopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] will now refer to Figures 1 to 5 An embodiment of the present invention will be described.

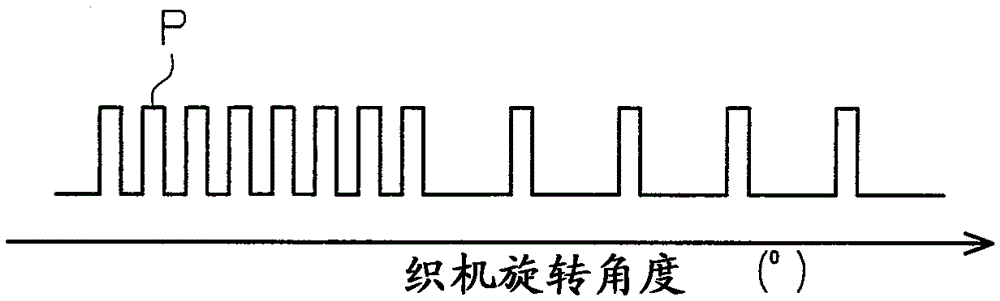

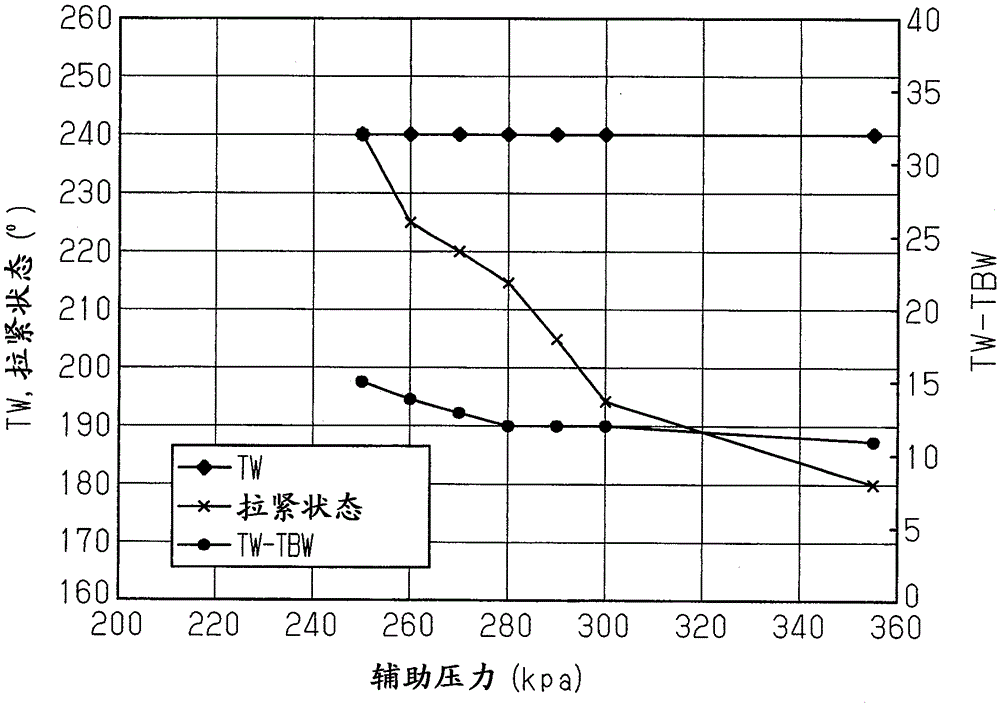

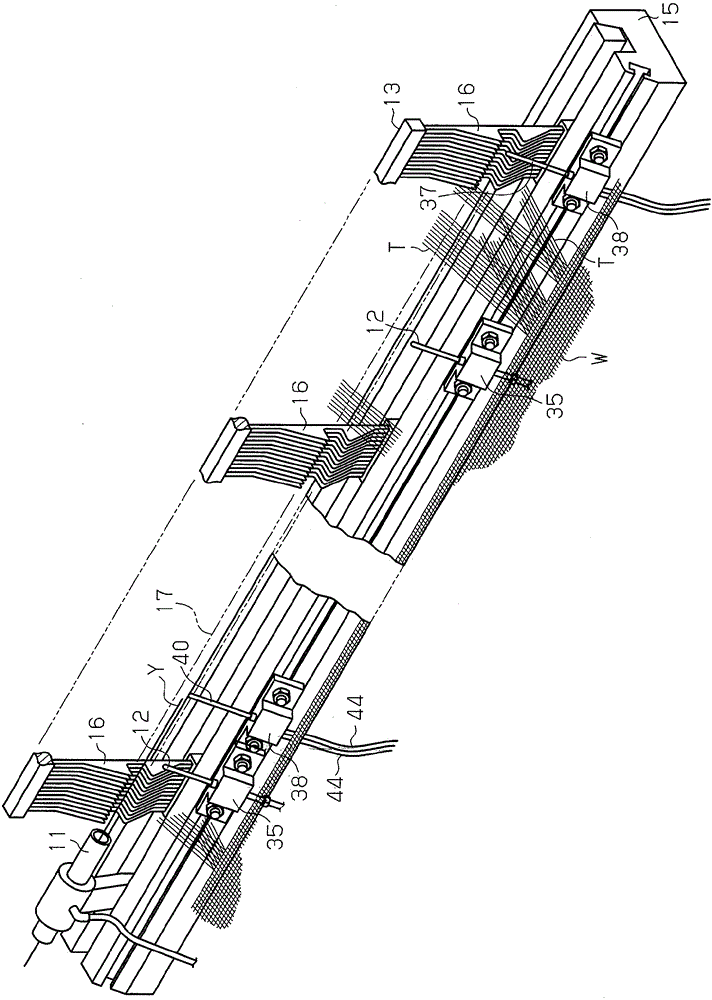

[0019] Such as figure 1 and 2 As shown in , the air jet loom includes a main nozzle 11 used in weft insertion, an auxiliary nozzle 12 used in weft insertion, a reed 13, and a weft yarn measuring and storing device 14 of winding type. Such as figure 2 As shown in , the main nozzle 11 , the auxiliary nozzle 12 and the reed 13 are fixed to the sley 15 . The reed 13 comprises a plurality of reed teeth 16 arranged in the weft insertion direction. Each reed tooth 16 has a guide notch 16a ( image 3 shown in ). The guide recesses 16 a of the reed teeth 16 form passages or reed passages 17 in the reed 13 .

[0020] Such as figure 1 As shown in , the main nozzle 11 is connected to a sump 19 for the main nozzle 11 via a pipeline. The main nozzle tank 19 is connected to the source pressure tank 18 . The solenoid valve 20 is provided between the main nozzle 11 and the main noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com