Method for enabling cement or concrete to have wave absorbing performance and dense surface by using silicon dioxide (SiO2) coated magnetic nanoparticles

A technology of magnetic nanoparticles and concrete surface, which is applied in the surface wave absorbing modification of cement and concrete. Cement or concrete has wave absorbing performance and compact surface field, and achieves the effect of strong magnetism, suitable for mass production and application, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

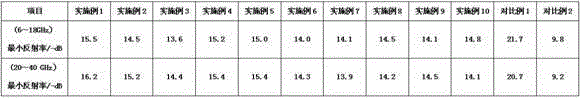

Examples

Embodiment 1

[0026] 0.1 g of Fe synthesized by co-precipitation method 3 o 4 Disperse nanoparticles in 20mL water, add 20mL ethanol and 0.1mL tetraethyl orthosilicate and mix evenly, then add 0.1mL ammonia water with a concentration of 20%, and stir at 15°C for 6h to prepare MFe 2 o 4 / SiO 2 Water dispersion: spray the water dispersion containing nanoparticles on the concrete test block under the magnetic field as the driving force. After testing, the surface hardness of the concrete has been significantly enhanced, and the reflectivity has been significantly reduced, showing good wave absorption. performance.

Embodiment 2

[0028] 0.1 g of Fe synthesized by co-precipitation method 3 o 4 Disperse nanoparticles in 30mL water, add 80mL ethanol and 0.2mL tetraethyl orthosilicate and mix evenly, then add 0.15mL ammonia water with a concentration of 23%, and stir at 30°C for 6h to obtain MFe 2 o 4 / SiO 2 Water dispersion liquid; under the magnetic field as the driving force, the solution containing nanoparticles is sprayed on the concrete test block. After testing, the surface hardness of the concrete is enhanced and it has wave-absorbing properties.

Embodiment 3

[0030] 0.1 g of Fe synthesized by co-precipitation method 3 o 4Disperse nanoparticles in 40mL water, add 100mL ethanol and 0.2mL tetraethyl orthosilicate and mix evenly, then add 0.2mL ammonia water with a concentration of 25%, and stir at 50°C for 6h to obtain MFe 2 o 4 / SiO 2 Water dispersion liquid; the solution containing nanoparticles is painted on the concrete test block under the magnetic field as the driving force. After testing, the surface hardness of the concrete is enhanced and it has wave-absorbing properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com