Adjusting mechanism for steering tubular column

A steering column and adjustment mechanism technology, applied in the field of auto parts, can solve problems such as poor structural reliability and operation convenience, complex connection structure between cams, handles and friction plates, etc., and achieve simple and easy adjustment operation and simple structure , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

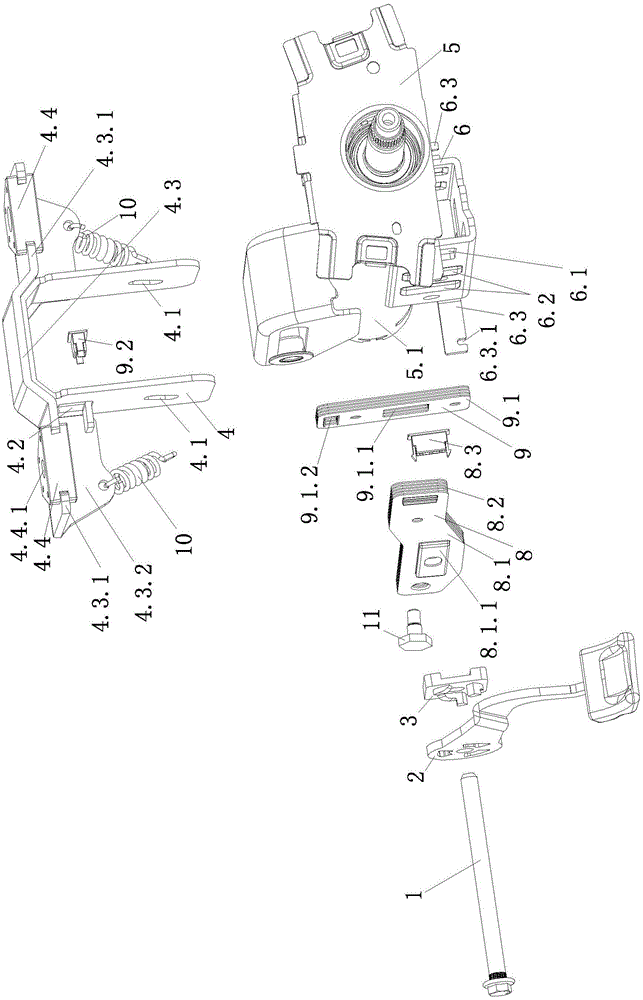

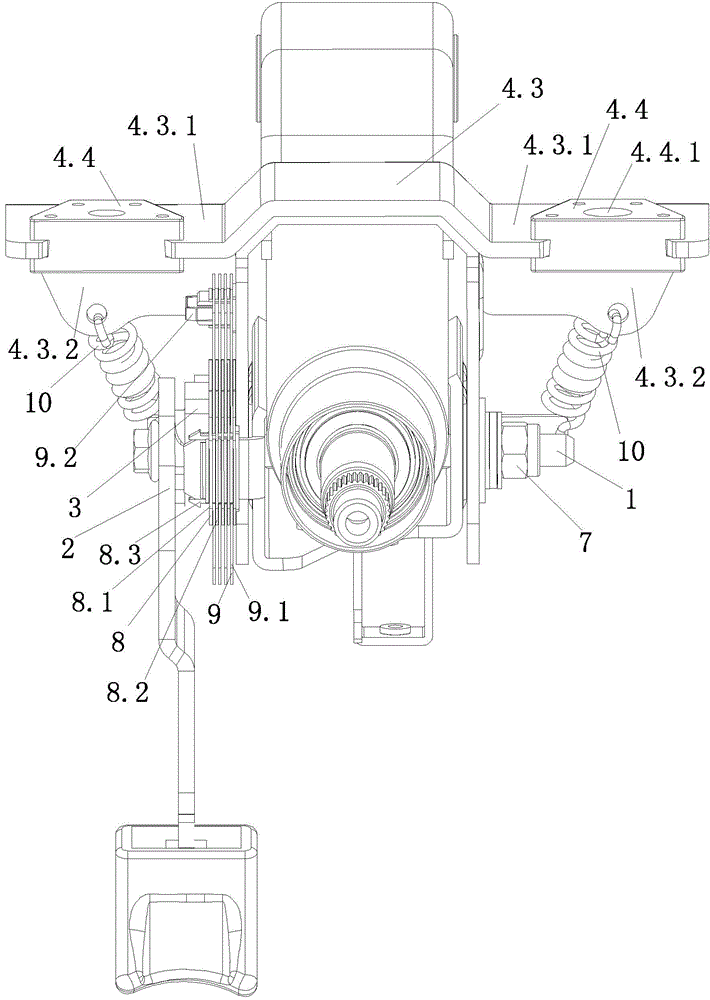

[0017] like figure 1 , figure 2 and image 3As shown, the present invention includes a connecting bolt 1, an adjusting handle 2, a cam 3, a fixed bracket 4, a steering column assembly 5, a lower bracket 6, an axial friction plate group 8 and a radial friction plate group 9; the steering column assembly Component 5 includes a steering column 5.1; wherein the structural details of the connecting bolt 1, the adjustment handle 2, the steering column assembly 5 and the structural details of the left side of the cam 3 are not repeated here because they are known technologies; 4 is an inverted U shape, and the fixed bracket 4 is fixedly connected to the cross beam of the vehicle; the lower bracket 6 is U-shaped, and the free ends of the two side walls of the lower bracket 6 are fixedly connected to the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com