A coupler buffer

A buffer and coupler technology, which is applied to railway car body parts, traction devices, transportation and packaging, etc., can solve the problems of the buffer effect of the coupler buffer, the difficulty of increasing the impact speed, and the large impact force, and achieve a good buffer effect. , The impact speed of the carriage is high, and the effect of improving stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

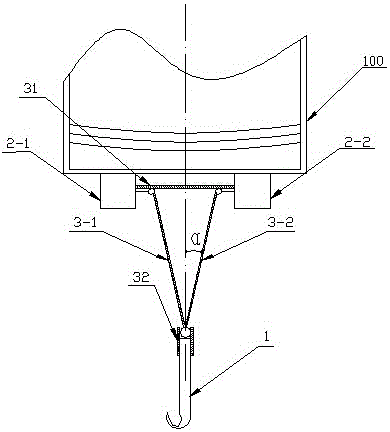

[0017] A coupler buffer, comprising a coupler 1, a left buffer 2-1 and a right buffer 2-2, the left buffer 2-1 and the right buffer 2-2 are arranged and installed in a car box along the width direction of a carriage 100. 100 at the bottom of both ends, the left buffer 2-1 is installed on the left side of the central axis of the car box, the right buffer 2-2 is installed on the right side of the central axis of the car box, and the coupler 1 is installed along the car box. The central axis of 100 is set at the bottom of both ends of the car box 100, and a limit push mechanism is installed between the left buffer 2-1 and the right buffer 2-2 and the coupler 1, and the limit push mechanism includes a left buffer. The push rod 3-1, the push rod 3-2, the lateral limiter 31 and the limiter 32 in the longitudinal direction, the left push rod 3-1 is installed on the left buffer 2-1 and the Between the coupler 1, the right push rod 3-2 is installed between the right buffer 2-2 and the ...

Embodiment 2

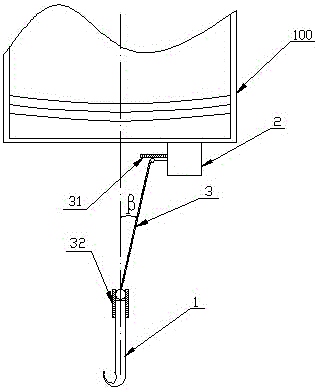

[0020] A coupler buffer includes a coupler 1 and a buffer 2, the buffer 2 is arranged and installed at the bottom of both ends of the car box 100 along the width direction of the car 100, and the coupler 1 is arranged along the central axis of the car box 100. At the bottom of the end, the buffer 2 is located on the right side of the central axis of the car box 100 , a limit push mechanism is installed between the buffer 2 and the coupler 3 , and the limit push mechanism includes a push rod 3 , a transverse limiter 31 and a longitudinal limiter 32, the push rod 3 is installed between the buffer 2 and the coupler 1, and the inner end of the push rod 3 is connected to the The compression end of the buffer 2 is connected, the outer end of the push rod 3 is connected with the hook tail of the coupler 1, and the inner end of the push rod 3 is assembled with the lateral limiter 31 , the inner end of the push rod 3 moves along the width direction of the carriage under the restriction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com