Novel three-color stirring device of 3D printer head

A technology of a 3D printer and a stirring device, applied in the field of printing, can solve the problems that the production of finished products of various colors is not easy to achieve, and increases the difficulty of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

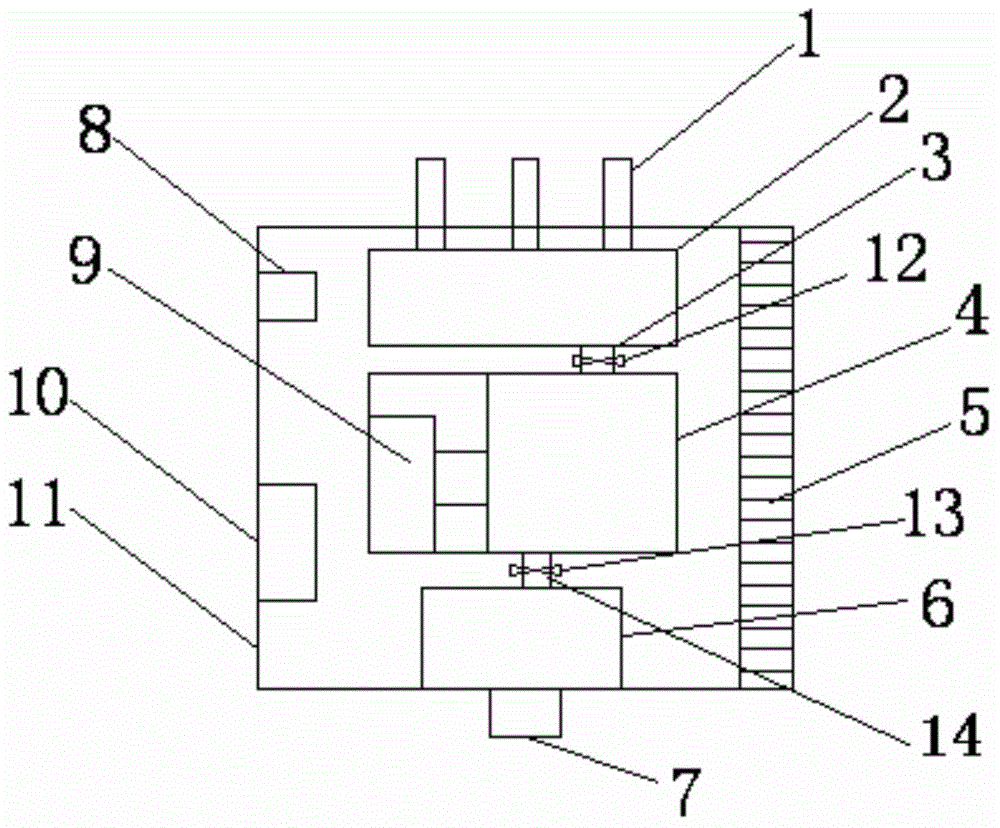

[0008] A new three-color stirring device for a 3D printer head proposed by the present invention, as shown in the figure, the stirring device includes a feed pipe port 1, a storage box 2, a first guide tube 3, a stirring chamber 4, and a heater 5 , the material box 6 to be used, the discharge port 7, the temperature tester 8, the stirring actuator 9, the stirring controller 10, the housing 11, the first electromagnetic valve 12, the second electromagnetic valve 13, and the second guide pipe 14; The feed pipe port 1 is connected to the material storage box 2, and the material storage box 2 and the stirring chamber 4 are connected through the first guide tube 3, and the first electromagnetic valve 12 is arranged on the first guide tube 3, A stirring actuator 9 is arranged in the stirring chamber 4, a second flow guide pipe 14 is arranged below the stirring chamber 4, and a second electromagnetic valve 13 is arranged on the second flow guide pipe 14, and the second flow guide pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com