A kind of manufacturing method of delaying body of electronic detonator

An electronic detonator and manufacturing method technology, applied in the direction of detonator, offensive equipment, etc., can solve the problems of inaccurate welding positioning, low production efficiency, blind fire of the detonator, etc., and achieve the improvement of tensile strength, welding quality and work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the utility model is further described below, but the scope of protection is not limited to the description.

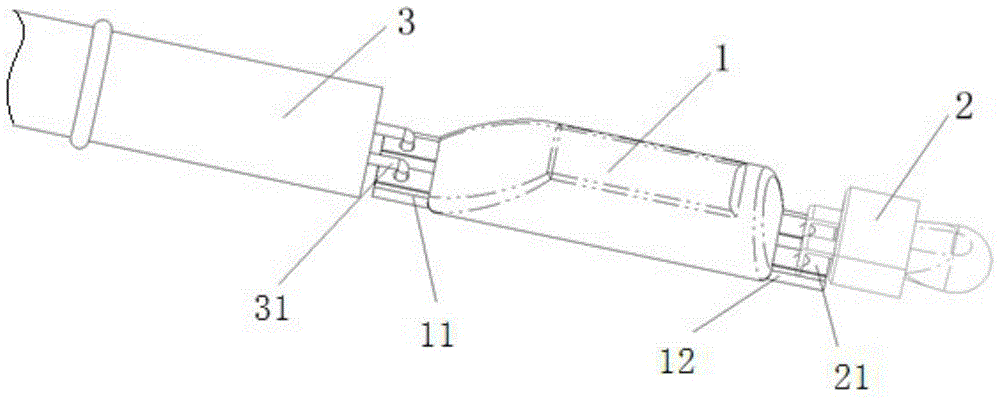

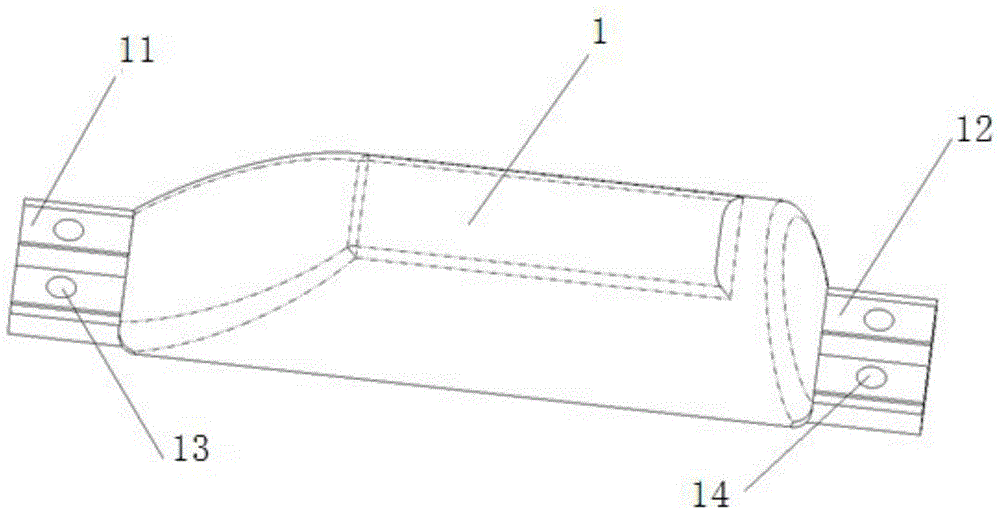

[0023] A kind of electronic detonator extension body manufacturing method provided by the present invention, such as Figure 1~5 As shown, the electronic detonator delay body includes an electronic delay circuit board 1, an ignition charge 2 and a detonator foot wire 3, and the manufacturing method includes the following steps:

[0024] (1) make the detonator foot wire connection hole 13 that can pass through the pin of the detonator foot wire 3 respectively by molding or cutting the detonator foot wire pad 11 at one end of the electronic delay circuit board 1, the same The method is to make a charge connection hole 14 that can pass through the pin of the ignition charge 2 on the charge pad 12 at the other end of the electronic delay circuit board 1;

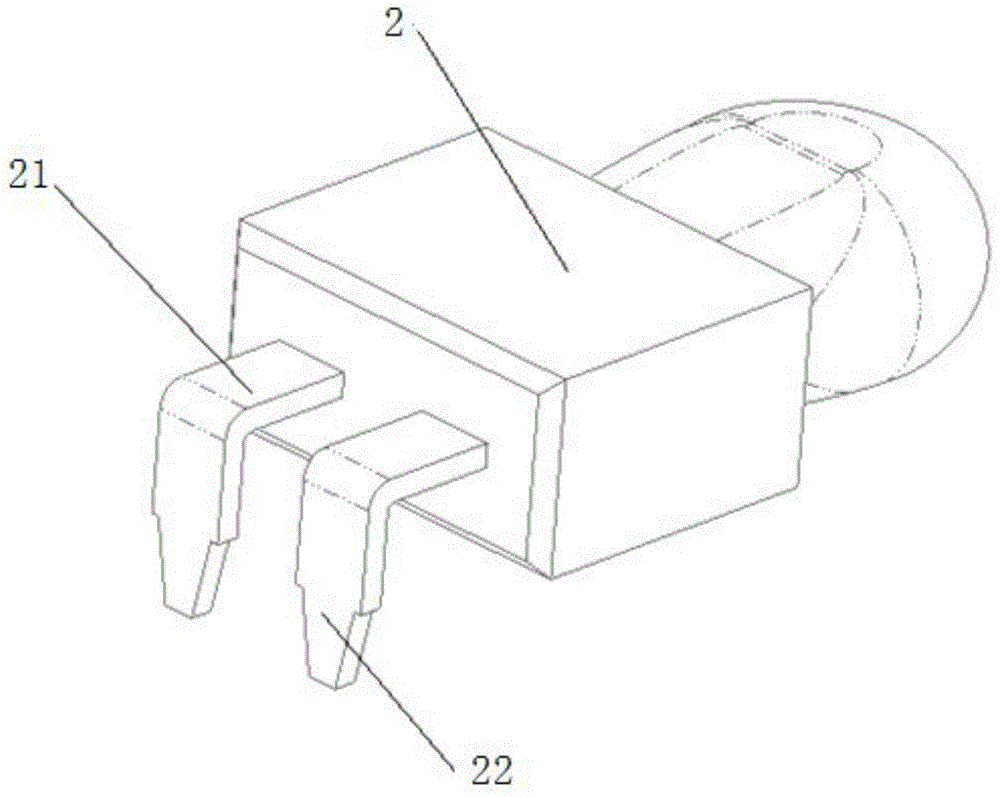

[0025] (2) The pin 21 of the ignition charge 2 is bent to form a bent section 22 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com