Steel reinforcement framework machine end portion longitudinal bar locker

A steel skeleton and locking device technology, which is applied to the manufacture of ring nets, other household appliances, household appliances, etc., can solve the problems of inconvenient operation, easy eccentricity, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

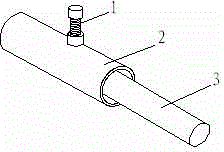

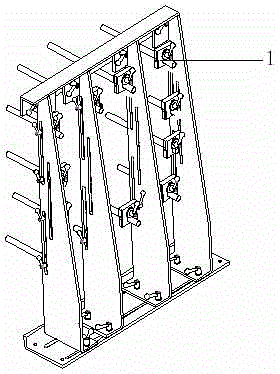

[0016] Such as figure 2 , image 3 , Figure 4 As shown, the threaded installation hole 9 provided on the rib block 2 of the end longitudinal rib locker 1 of the present invention is installed on the supporting component of the steel frame machine, that is, the end longitudinal rib adjustable fixed locking device, by bolts.

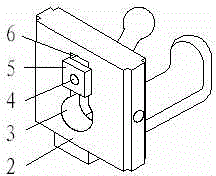

[0017] The rib piercing block 2 of the end longitudinal rib locker 1 of the present invention is provided with a circular rib piercing hole 3 and a rectangular locking hole 6. The rib piercing hole 3 communicates with the locking hole 6. Tight hole 6 width; Screw mandrel 4 is worn in the locking hole 6, and screw mandrel 4 is provided with elastic sleeve 12 and locking block 5 that are positioned at both sides of piercing rib block 2; Elastic sleeve 12 is provided with handle 11 and locking Pressing plate 8, the locking pressing plate 8 is an eccentric circle; the locking block 5 is provided with a threaded hole that is screwed with the screw mandrel 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com