Automatic rounding machine

A rounding machine and automatic technology, which is applied in the field of plate processing equipment, can solve the problems of low utilization rate of equipment, achieve the effect of improving quality, reducing rounding cost, and ensuring rounding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

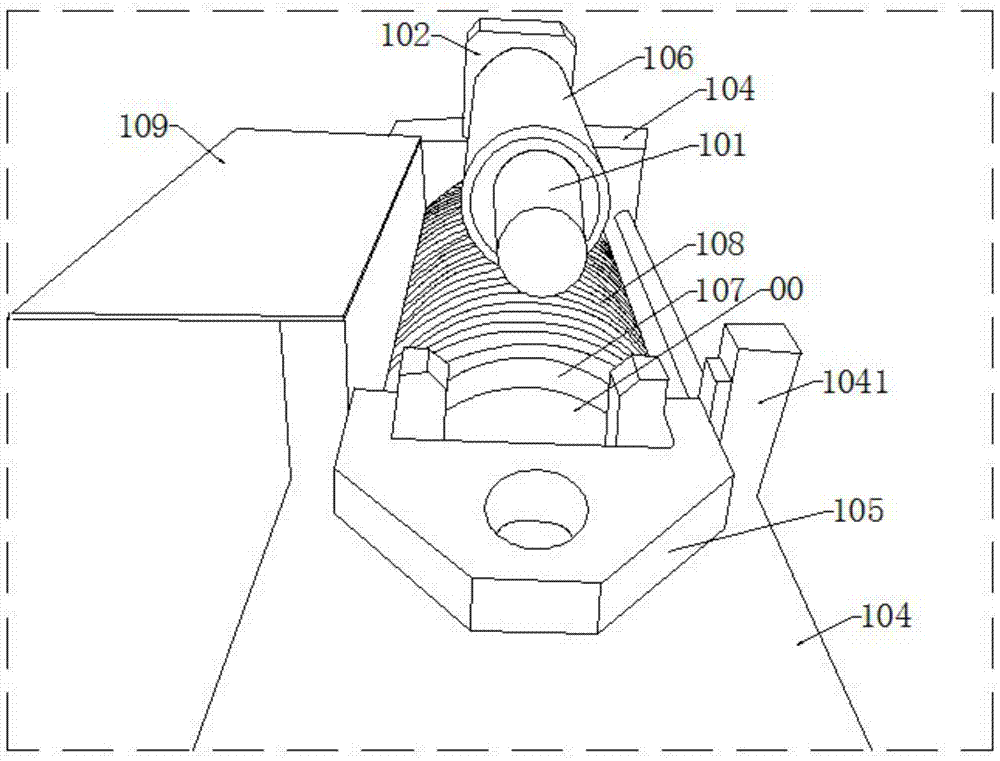

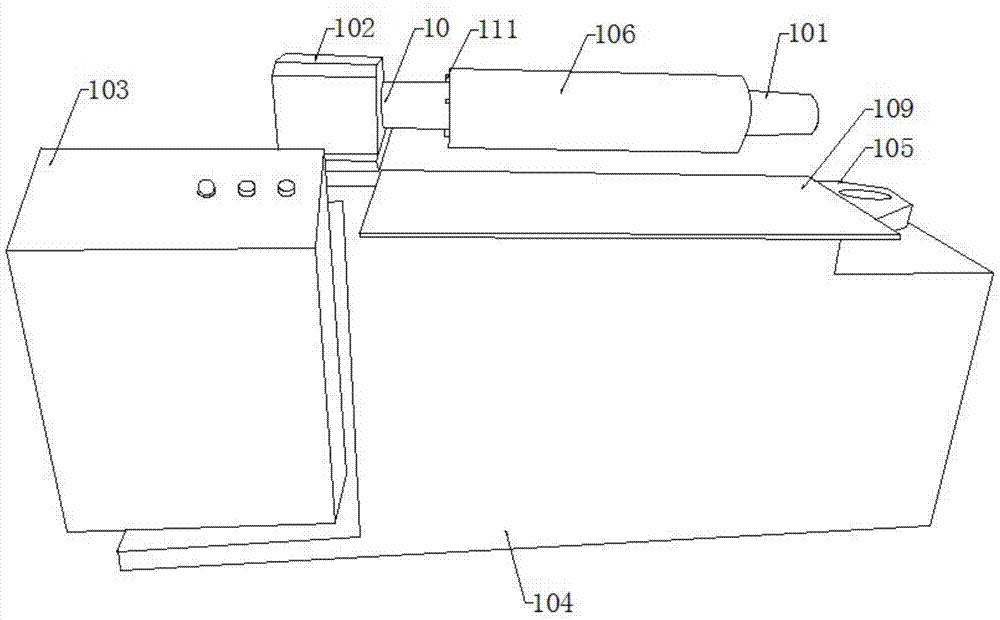

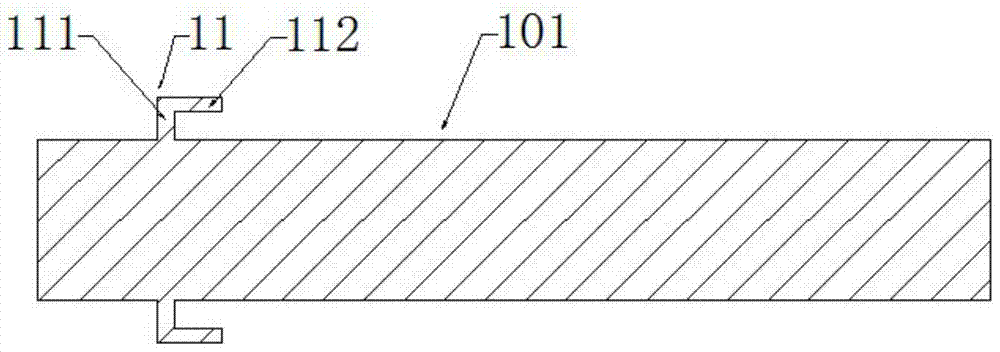

[0028] figure 1 It is a schematic diagram of the front structure of the automatic spheronizing machine provided in Embodiment 1 of the present invention; figure 2 It is a schematic diagram of the side structure of the automatic spheronizing machine provided in Embodiment 1 of the present invention; image 3 It is a schematic cross-sectional structure diagram of the upper roller of the automatic spheronizing machine provided by Embodiment 1 of the present invention; as shown in the figure, the automatic spheroidizing machine provided by Embodiment 1 of the present invention includes: a first motor 102 for driving the upper roller 101, The second motor (inside the cabinet, not shown in the figure) used to drive the lower roller (the lower roller is fixedly sleeved on the periphery, not shown in the figure) is used to control the opening and closing of the first motor 102 and the second motor platform 103, the first motor 102 is fixed on the rear panel of the cabinet 104, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com