Roller-type continuous cold-bending forming method of stainless steel roof side beams

A roof side beam and cold-bending forming technology, which is applied in the roll-type continuous cold-bending forming of stainless steel roof side beams for subway car bodies, and in the field of roller-type continuous cold-bending forming of stainless steel roof side beams. Problems such as low processing efficiency of side beams, difficulty in controlling the size of arcs, and lack of continuous cold-bending forming have achieved the effects of flexible size, fast and flexible delivery, and outstanding performance in corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

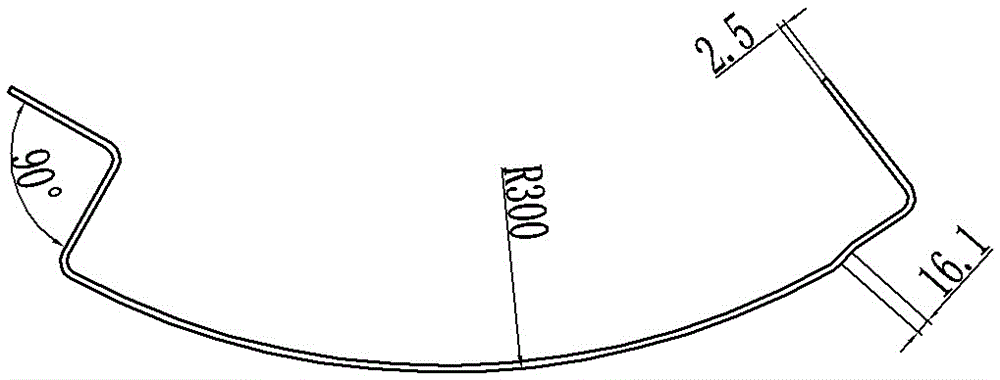

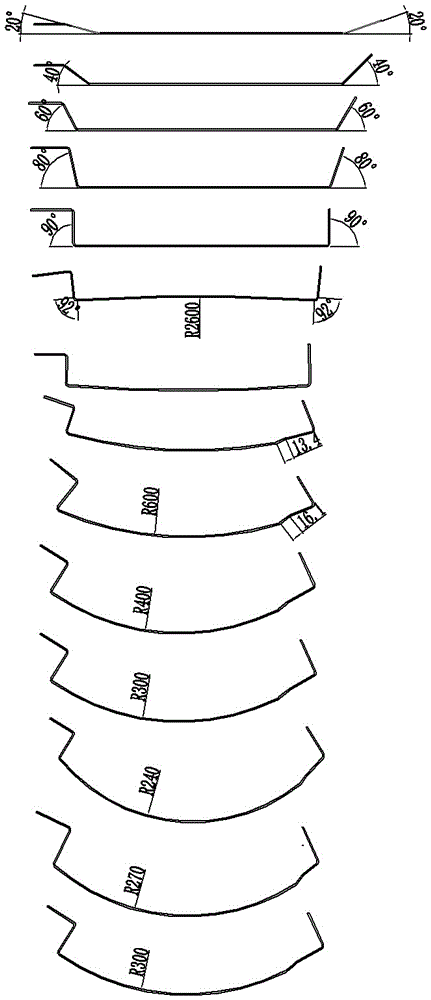

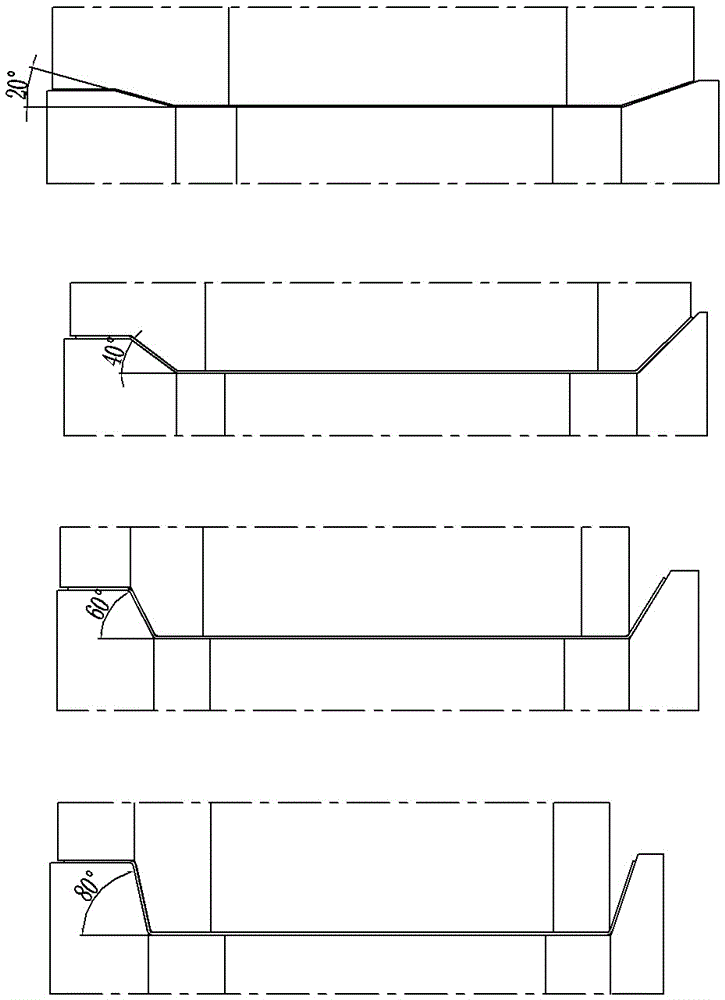

[0028] Combine below Figure 1 to Figure 7 The present invention is described in detail with specific examples.

[0029] The important step of utilizing the method of the present invention to manufacture the roof side beam is continuous cold-bending deformation, and the key to continuous cold-bending deformation is the selection of the deformation process, mode and deformation angle. The specific manufacturing process of the roof side beam includes:

[0030] (1) Slitting strip steel: Slitting stainless steel coils into the width designed by the process on the slitting unit to ensure that the surface is clean and free of scratches and other defects;

[0031] (2) Uncoiling and leveling: the slitting stainless steel coil is opened by the uncoiler on the cold roll forming unit, and the strip is leveled by the leveler;

[0032] (3) Shear butt welding: After cutting the head of the strip steel, use a welding machine to weld the head of the strip steel billet and the tail of the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com