A fully automatic machine for making phoenix rolls

A fully automatic, phoenix rolling technology, which is applied in the direction of rolling dough sheet machines, baking, dough processing, etc., can solve the problems of insufficient standard size, affecting work efficiency, uneven temperature and color, etc., to reduce the production area and taste Crunchy and delicious, simple and easy-to-understand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

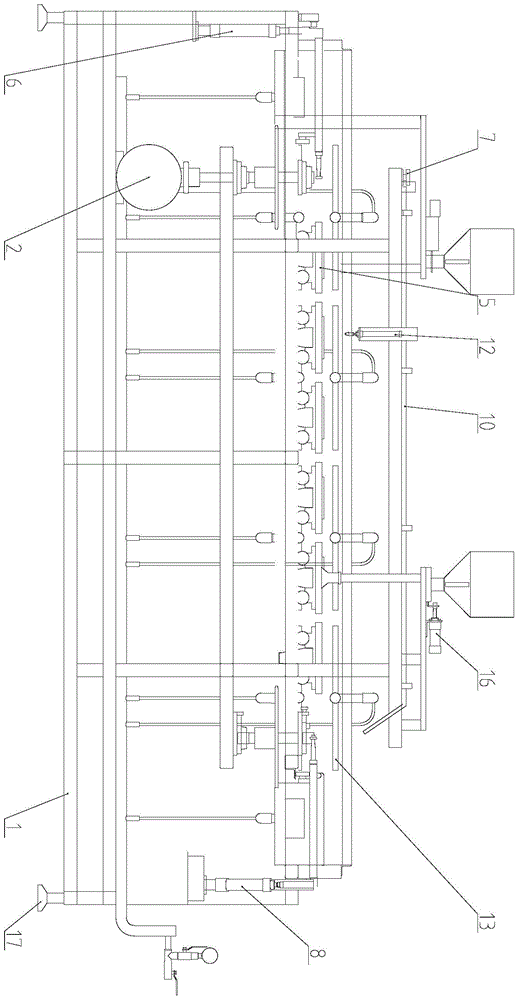

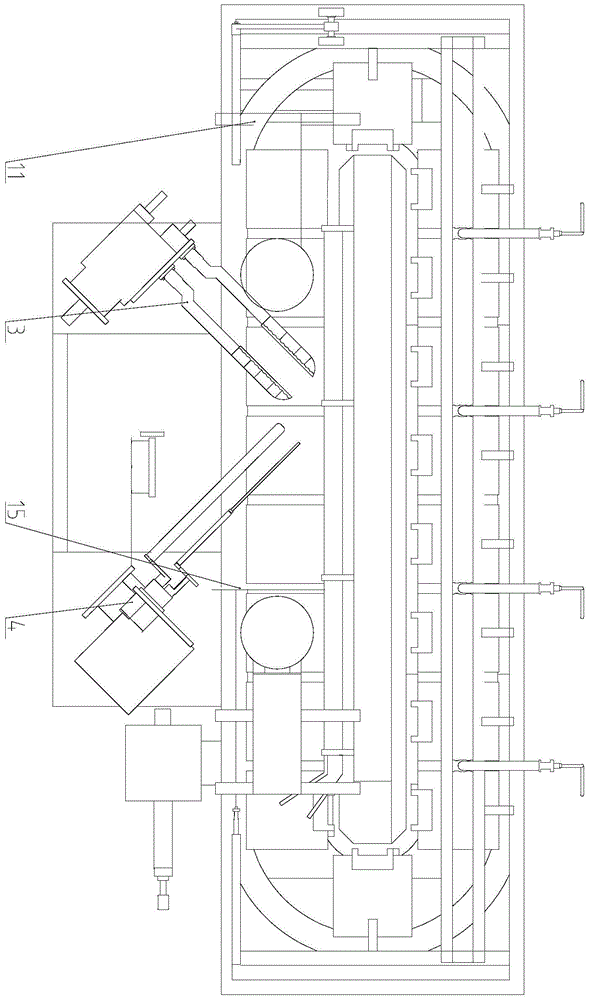

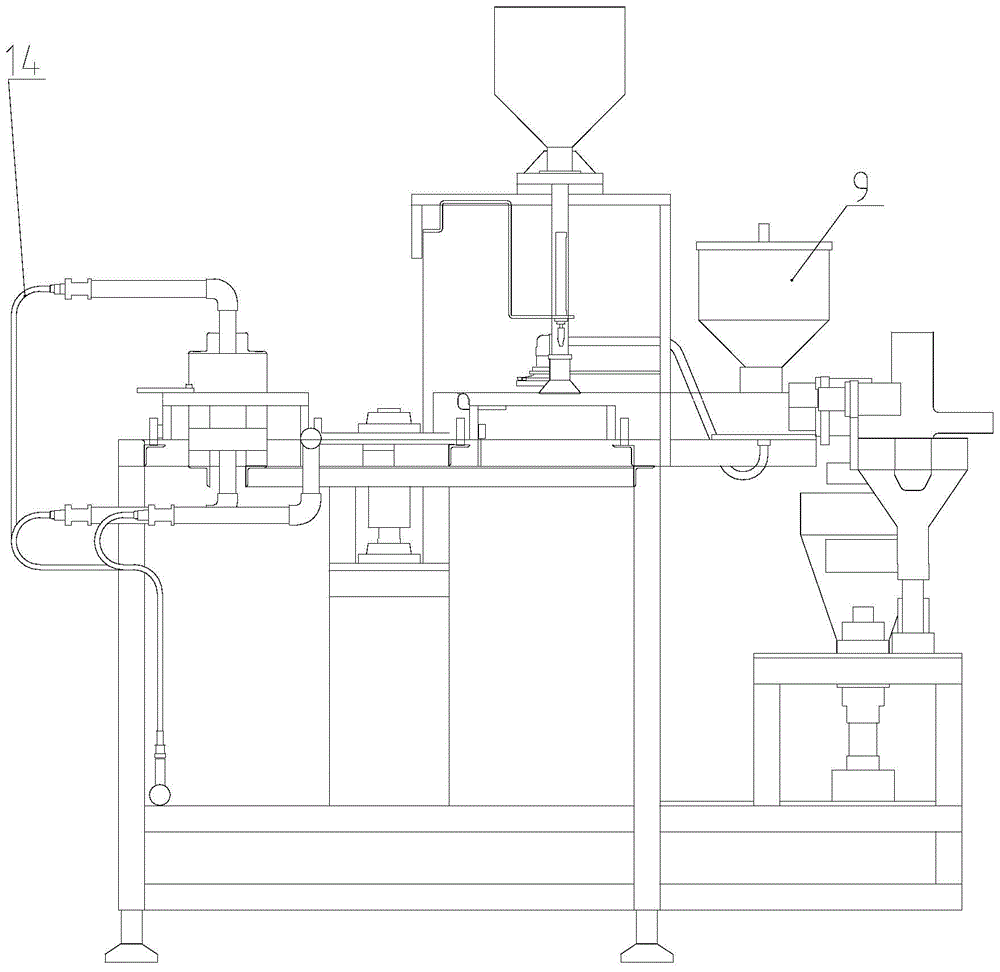

[0017] Such as Figure 1-3 As shown, a fully automatic machine for making phoenix rolls according to the embodiment of the present invention includes: a frame 1, a transmission assembly 2 is installed on the lower part of the frame 1, and a track assembly 11 is arranged on the transmission assembly 2, And on described track assembly 11, formwork assembly 5 is provided with, and described formwork assembly 5 comprises formwork, and the front portion of described frame 1 is installed with the mold opening assembly 6 that is used to open described formwork, and described frame 1 rear The mold closing assembly 8 for closing the template is installed on the upper part; the air circuit system 14 is installed behind the frame 1, and the air circuit system 14 supplies a plurality of heating systems 13 installed on the upper part of the frame 1 Gas, the upper part of the frame 1 is equipped with a grouting mechanism 9; the template limit assembly 10 is installed on the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com