A complex geotechnical engineering reliability analysis device

A technology of geotechnical engineering and analysis device, applied in the field of geotechnical engineering, can solve problems such as adjusting step size, and achieve the effects of reducing workload, avoiding data errors and loss, and facilitating reliability analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

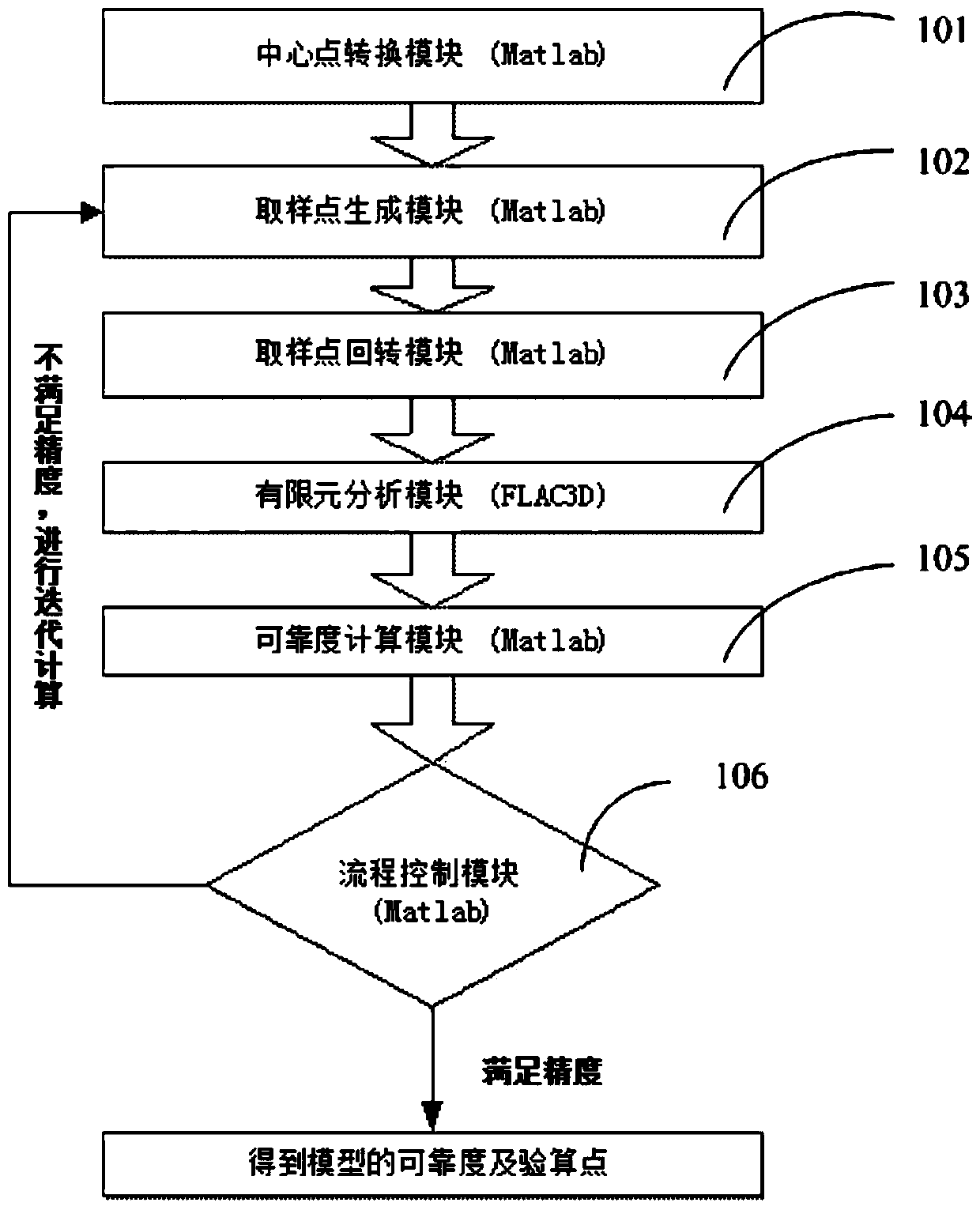

[0043] Such as figure 1 As shown, a complex geotechnical engineering reliability analysis device of the present invention consists of a center point conversion module 101, a sampling point generation module 102, a sampling point rotation module 103, a finite element analysis module 104, a reliability calculation module 105 and a process control module 106, wherein the central point conversion module 101, sampling point generation module 102, sampling point rotation module 103, reliability calculation module 105 and process control module 106 can all be realized by the functions of the numerical calculation software Matlab; and the finite element analysis module 104 Then the finite element analysis and calculation can be carried out through the finite difference program FLAC3D; since the data exchange of sampling points and limit equation values needs to be carried out between Matlab and FLAC3D, the text file is used to realize the exchange between the two programs in this emb...

Embodiment 2

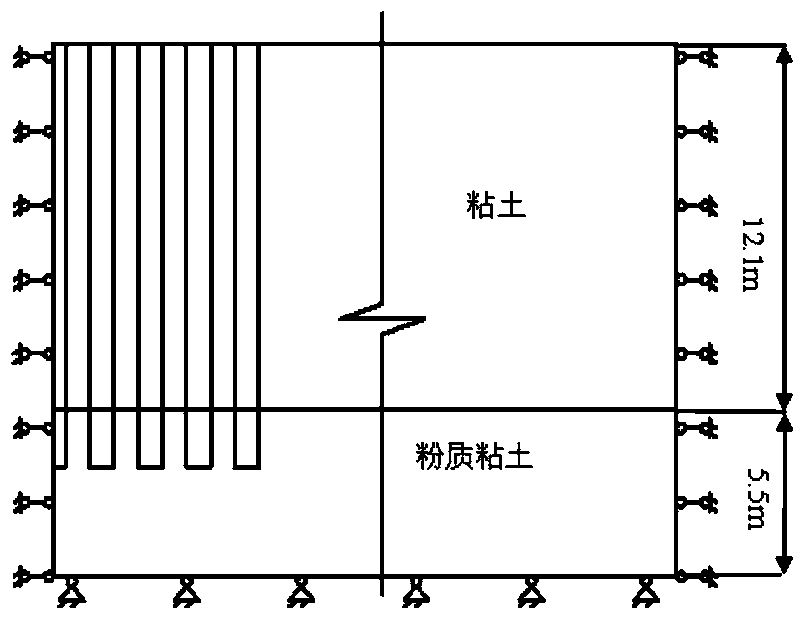

[0051] The reliability analysis device and principle proposed by the present invention will be introduced below by taking a soft soil foundation reinforced with deep mixing piles as an example. The layout of the investigated deep mixing piles and the distribution of soil layers are as follows: figure 2 and image 3 shown. The foundation soil is divided into two layers, the clay layer from 0 to -12.1 meters, and the silty clay layer from -12.1 to -17.6 meters. The pile diameter of the deep mixing pile is 0.9m, the pile spacing is 1.6m, and the pile length is 14m. The load on the foundation is 85kPa.

[0052] with E s 、c s , Represent the elastic modulus, cohesion and internal friction angle of clay respectively, and E p 、c p , Represent the modulus, cohesion and internal friction angle of the deep-stirred pile, respectively. The soil layer and deep mixing pile parameters in this embodiment are shown in Table 1. The mechanical properties of soft soil and reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com