Liquid level control method of dual-loop water tank based on model prediction

A technology of model prediction and liquid level control, which is applied in the direction of liquid level control, adaptive control, general control system, etc. It can solve the problems of difficult physical modeling parameters and not a modeling method of the double circuit water tank liquid level system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

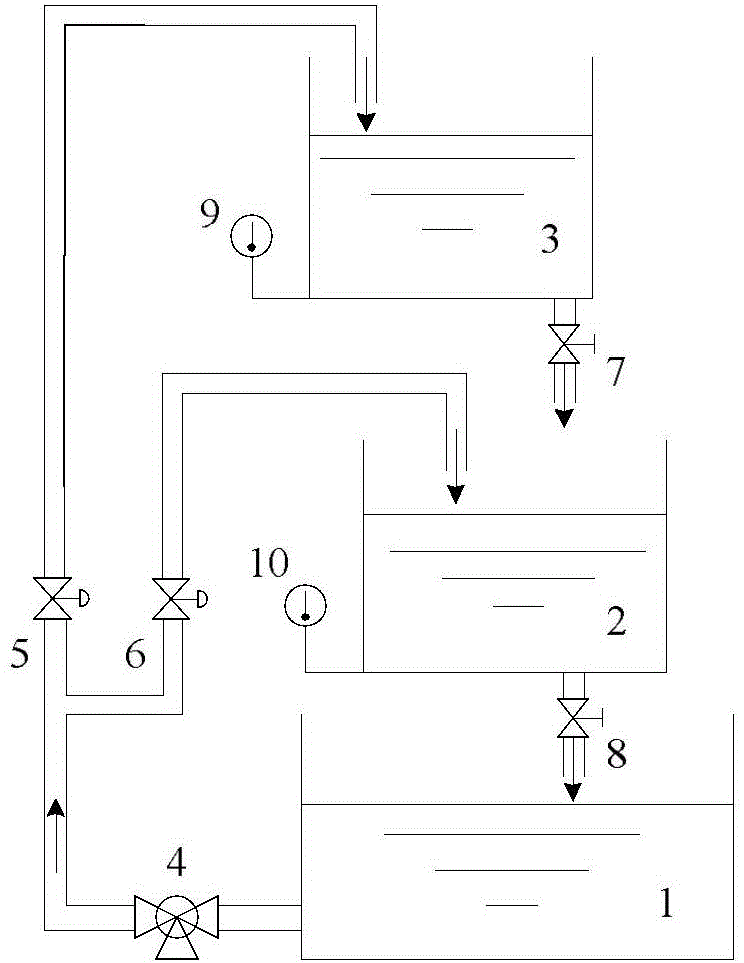

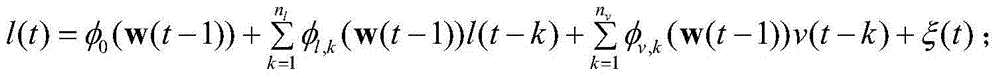

[0019] The connection block diagram of the double circuit water tank liquid level system of the present invention is as follows figure 1 As shown, the double-circuit water tank liquid level system is a double-circuit continuous water supply system composed of three water tanks. Among them: the water in the first water tank 1 is pumped out by the water pump 4, and injected into the third water tank 3 and the second water tank 2 through the electric control valves 5 and 6 respectively; the water in the third water tank 3 and the second water tank 2 is respectively passed through the manual valve 7 , 8 leaked to the second water tank 2 and the first water tank 1; the opening of the electric control valve 5 and the valve 6 are used to control the water intake intensity; the liquid level sensors 9 and 10 are used to detect the third water tank 3 and the second water tank 2 respectively liquid level in .

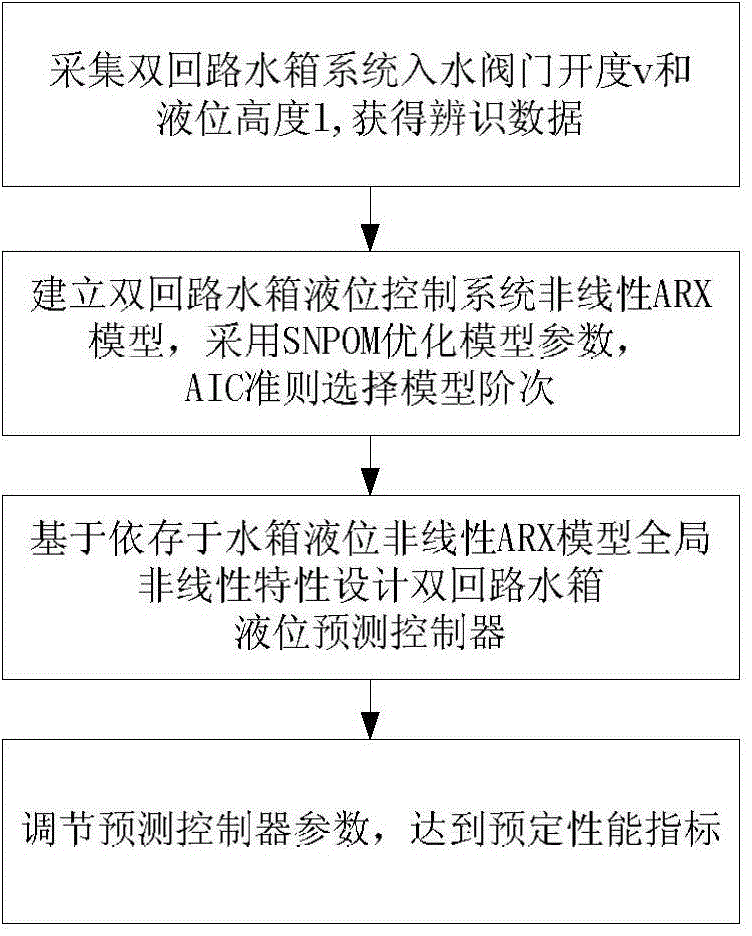

[0020] The control method of the present invention is as figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com