Safety composite type brake drum with rapid heat dissipation and anti-burst

A brake drum and anti-explosion technology, applied in the field of brake drums, can solve problems such as easy bursting of brake drums, and achieve the effects of eliminating potential safety hazards, improving heat dissipation, and preventing bursting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

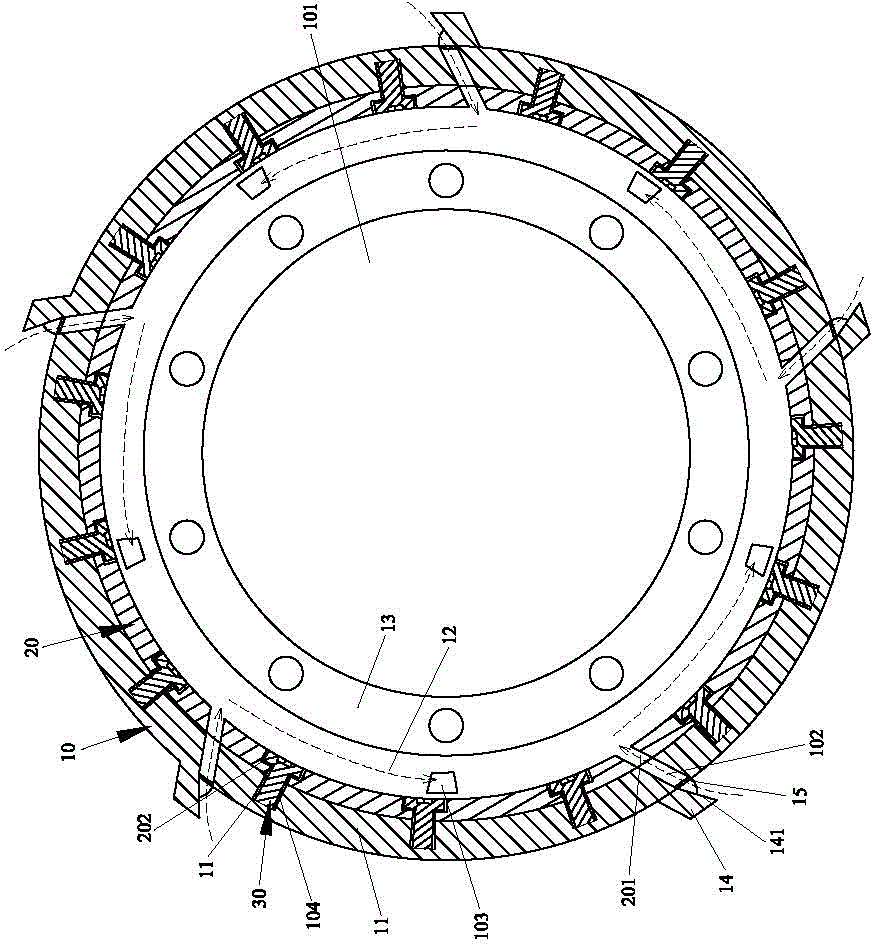

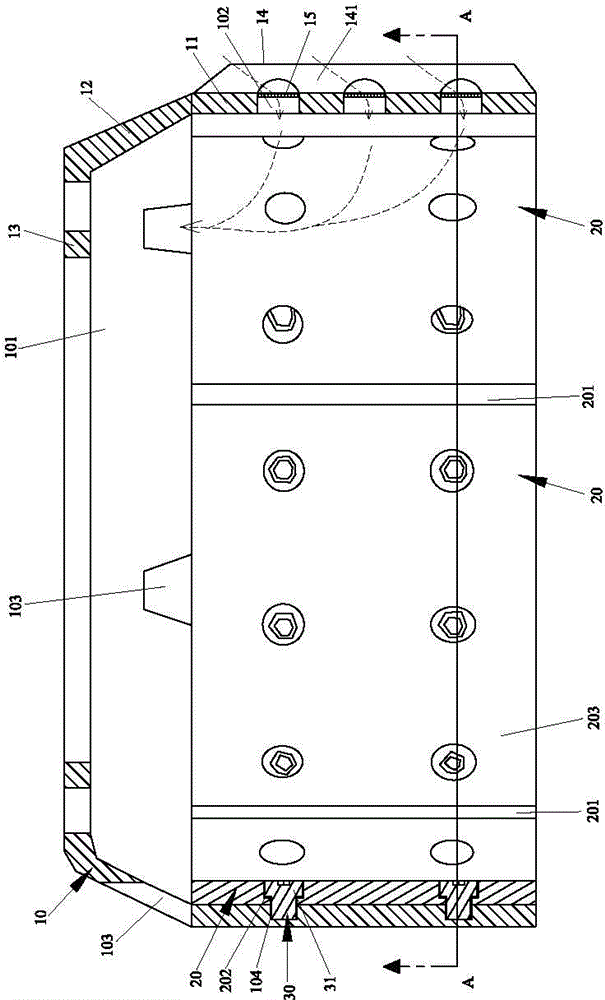

[0031] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the brake drum shell 10.

[0032] The brake drum shell 10 has an inner cavity 101. The brake drum shell 10 includes a main body part 11, a connecting part 12 and a mounting part 13 which are sequentially integrally formed and connected. A plurality of ribs 14, each rib 14 extends axially, and the ribs 14 are arranged obliquely along the rotation direction of the brake drum shell 10 to achieve a better wind resistance effect, and each rib 14 has a windshield surface 141 The connection between the windshield surface 141 and the outer ring wall of the main body 11 is provided with an air inlet hole 102, the air inlet hole 102 communicates with the inner cavity 101, and the air inlet hole 102 is an inclined hole, so that the wind enters the inner cavity In the cavity 101, and the air inlet 102 is provided with a filter screen 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com