Method for optimizing mining boundaries of underlying seams of strip mines

A technology of mining realm and optimization method, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of different economic stripping ratios of coal seams and the inability to maximize the economic benefits of ore deposit mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

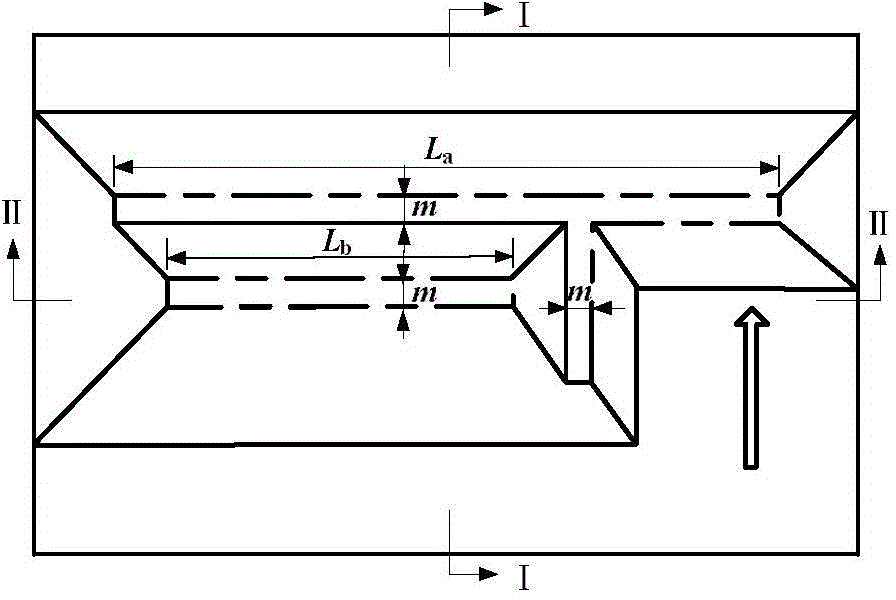

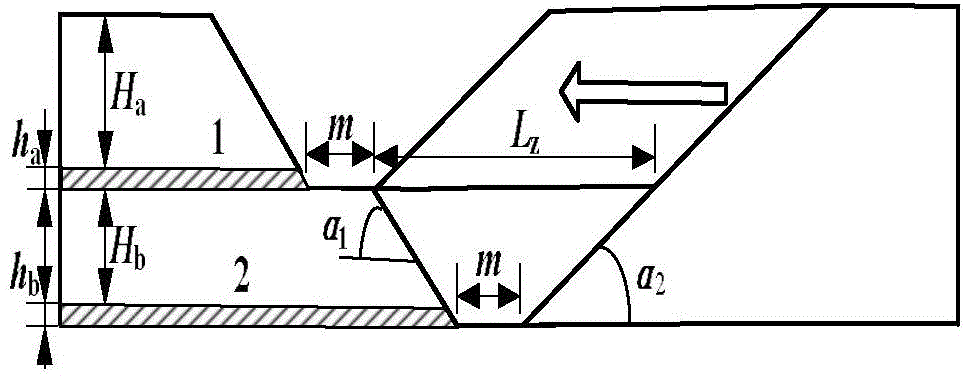

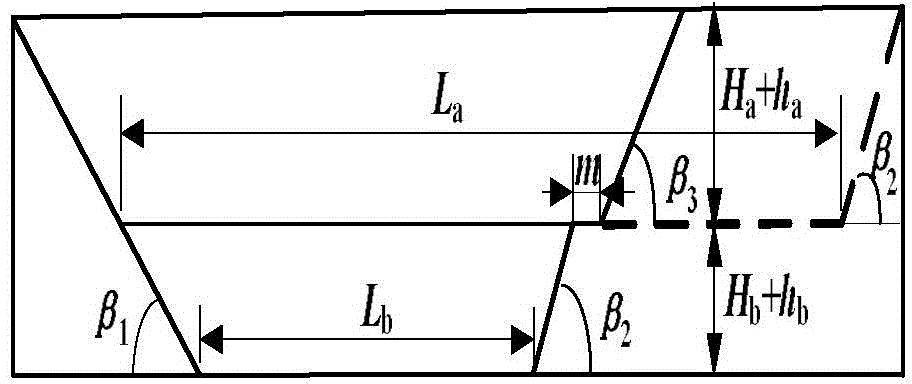

[0068] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0069] Taking a near-horizontal composite coal seam open-pit mine in Inner Mongolia as an example, there are 1 2 ,2 1 , No. 3 and other mineable coal seams, such as Figure 5 shown. In the preliminary design of the open-pit mine, it was determined that the main mining coal seam in the second mining area was 1 mineable in the whole area. 2 Coal seam, deep boundary with 1 2 Coal seam floor as boundary, 2 1 , No. 3 coal seam shall not be exploited. In line with the principle of making full use of coal resources and increasing resource recovery, the mine carried out supplementary exploration on the second mining area of the open-pit mine. According to the supplementary survey report of the second mining area, at a distance of 1 2 The average depth of the coal seam is 65m, and there is No. 3 coal seam with an average thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com