A kind of same-bath dyeing method of dyeing acrylic cotton fabric with direct dye and cationic dye

A technology for cationic dyes and nitrile cotton fabrics, which is applied in the field of nitrile cotton fabric dyeing, can solve the problems of large consumption of energy and dyeing materials, low production efficiency, long process flow, etc., and achieve good economic benefits, improve performance, and process time. shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Firstly, the acrylic-cotton blended fabric is pretreated, the temperature is 90°C, the time is 1h, the bath ratio is 1:10, the pretreatment liquid components are: soda ash 3g / L, hydrosulfite 0.5g / L, JFC 2g / L, Soap powder 2g / L.

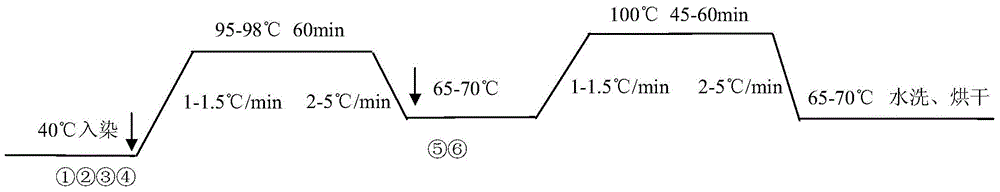

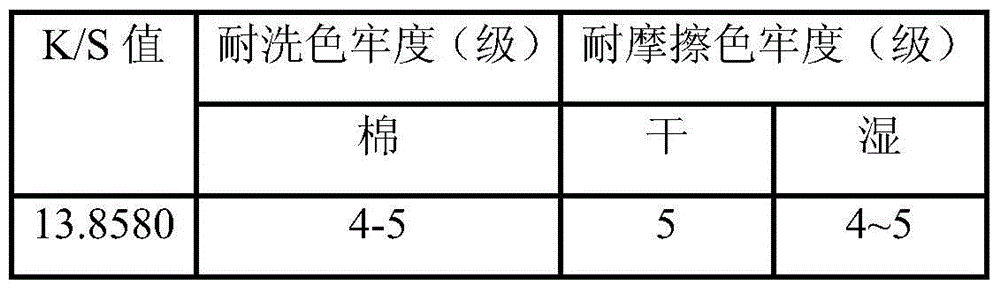

[0044] Prepare the dye solution (direct dye tinny red K-BE 2% o.w.f, Yuanming powder 10% o.w.f, leveling agent Pingping 02g / L, acetic acid 2.5% o.w.f, sodium acetate 1% o.w.f, pH value 4), heat up to 40°C, add acrylic cotton blended fabric sample (bath ratio 1:15), stir and dye for 5 minutes, heat up to 98°C at 1°C / min, stir and keep warm for 60 minutes, cool down to 65°C at 2°C / min, add cationic dyes and Dispersant (Astryla Chonghong GL-N3001% O.W.F, dispersant N 2g / L), heat up to 100°C at 1°C / min, stir and keep warm for dyeing for 60min, cool down to 65°C at 2°C / min, wash and solidify Color (fixing agent R-7551%owf, liquor ratio 1:10, 40°C treatment for 20min), drying, test performance (results are shown in Table 1).

[0045] Table 1

[004...

Embodiment 2

[0049] Firstly, the acrylic-cotton blended fabric is pretreated, the temperature is 90°C, the time is 1h, the liquor ratio is 1:10, the pretreatment solution components are: soda ash 3g / L, hydrosulfite 0.5g / L, JFC 2g / L, Soap powder 2g / L.

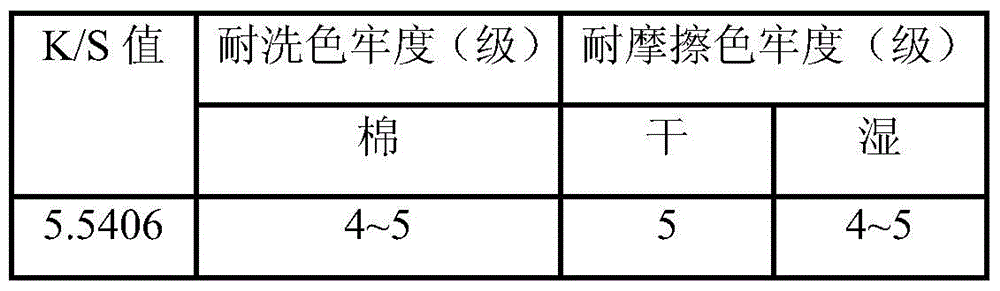

[0050] Prepare dye solution (direct dye Xilihuang K-2G 2% o.w.f, Yuanming powder 10% o.w.f, dispersant Pingping plus O2g / L, acetic acid 2.5% o.w.f, sodium acetate 1% o.w.f, pH value 4), heat up to 40 ℃, add acrylic cotton blended fabric sample (bath ratio 1:15), stir for 5 minutes, heat up to 98°C at 1°C / min, stir and keep warm for 60 minutes, cool down to 65°C at 2°C / min, add cationic dyes and disperse (Astryla Golden GL-E2001% o.w.f, dispersant N 2g / L), heat up to 100°C at 1°C / min, stir and keep warm for dyeing for 60min, cool down to 65°C at 2°C / min, wash and fix the color ( Color-fixing agent R-7551%owf, bath ratio 1:10, 20min at 40°C), drying, test performance (results are shown in Table 2).

[0051] Table 2

[0052]

[0053] (The...

Embodiment 3

[0055] Firstly, the acrylic-cotton blended fabric is pretreated, the temperature is 90°C, the time is 1h, the liquor ratio is 1:10, the pretreatment solution components are: soda ash 3g / L, hydrosulfite 0.5g / L, JFC 2g / L, Soap powder 2g / L.

[0056] Prepare the dye solution (direct dye Ceylon blue K-BE 2% o.w.f, Yuan Ming powder 10% o.w.f, dispersant Pingping plus O2g / L, acetic acid 2.5% o.w.f, sodium acetate 1% o.w.f, pH value 4), heat up to 40 ℃, add acrylic cotton blended fabric sample (bath ratio 1:15), stir for 5 minutes, heat up to 98°C at 1°C / min, stir and keep warm for 60 minutes, cool down to 65°C at 2°C / min, add cationic dyes and disperse agent (Astryla Chonglan GRL3001% o.w.f, dispersant N 2g / L), the temperature was raised to 100°C at 1°C / min, stirred and kept for dyeing for 60min, cooled to 65°C at 2°C / min, washed with water to fix the color (fixing Toner R-7551%owf, bath ratio 1:10, 40°C treatment for 20min), drying, test performance (results are shown in Table 3). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com